-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

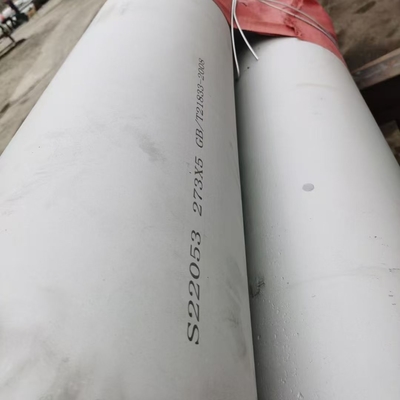

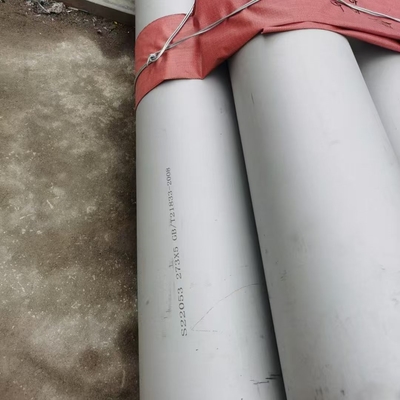

EN 1.4462 Duplex Stainless Steel Pipe Tube NB10 - NB400 Alloy Seamless Pipes for Oil and Gas

| Place of Origin | China |

|---|---|

| Brand Name | DELTA |

| Certification | ISO |

| Model Number | S31803 / S32205 / S22053 / 2205 |

| Minimum Order Quantity | 1000 kgs |

| Price | 7-10 USD/Kg |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | L/C,T/T,Western Union |

| Supply Ability | 4 Ton per week |

| Products | Stainless Steel Seamless Pipe | Grade | S31803 / S32205 / S22053 / 2205 |

|---|---|---|---|

| Diameter | DN10 - DN400 | Length | 6m Or Custom Cutting Any Length As Request |

| Standard | ASTM EN | Service | Cutting |

| Loading Port | Shanghai Port | Thickness | 4.0 - 50.0mm |

| Highlight | EN 1.4462 duplex stainless steel pipe,seamless stainless steel pipe for oil and gas,duplex stainless steel tube NB10 to NB400 |

||

EN 1.4462 Duplex Stainless Steel Pipe Tube NB10 - NB400 Alloy Seamless Pipes for Oil and Gas

Products Specification

| Products Name | Duplex 2205 Stainless Steel Seamless Pipe |

Grade: |

304 304L 309S 310S 314 315 316L 316Ti 317L 321 329 347H 410 2205 2507 S32760 904L 254SMO and equal grade in GB JIS EN DIN Standard |

| Standards: | ASTM A213M-94b ASTM A249M-94a ASTM A269-94a ASTM A312M-94b,ect. ASTM A790 |

| DIN 17456-85 DIN 17458-85 DIN 17459-92.ect | |

| JIS G3446-1994 JIS G3448-1997 JIS G3459-1997 JIS G3463-1994,ect. | |

| GB13296-1991 GB14975-2002 GB14976-2002,ect. | |

| Size: | ND5 - DN400 |

| Length: | 6m length or cutting any length as request |

| Applications: | fluid and gas transport, structure , boiler, heat exchanger, super heater |

1. Introduction

EN 1.4462 (also known as X2CrNiMoN22-5-3, UNS S31803/S32205, or Duplex 2205) is a ferritic-austenitic stainless steel widely used in aggressive environments. Its dual-phase microstructure combines high strength (approximately twice that of standard austenitic steels like 316L) with exceptional corrosion resistance, especially in chloride-rich settings such as oil and gas extraction, seawater systems, and chemical processing. Seamless pipes in nominal bore (NB) sizes from NB10 (10 mm) to NB400 (400 mm) are critical for high-pressure applications in offshore platforms, pipelines, and heat exchangers.

2. Chemical Composition

The alloy’s corrosion resistance stems from its balanced composition, with chromium for passivation, molybdenum for pitting resistance, and nitrogen for strength stabilization:

Table 1: Chemical Composition (wt.%)

| Element | Range | Key Role |

|---|---|---|

| Cr | 21.00–23.00% | Corrosion resistance |

| Ni | 4.50–6.50% | Austenite stability |

| Mo | 2.50–3.50% | Pitting/crevice resistance |

| N | 0.08–0.20% | Strength enhancement |

| C | ≤0.030% | Prevents sensitization |

| Mn | ≤2.00% | Austenite formation |

| Si | ≤1.00% | Deoxidation agent |

| P, S | ≤0.030%, ≤0.020% | Impurity control |

3. Mechanical Properties

1.4462 offers superior mechanical performance compared to standard austenitic grades, enabling thinner pipe walls and weight reduction:

Table 2: Mechanical Properties (Solution-Annealed)

| Property | Value Range | Test Condition |

|---|---|---|

| Tensile Strength | 620–880 MPa | ≥640 MPa typical |

| Yield Strength (0.2%) | 450–550 MPa | Min. 450 MPa |

| Elongation (A₅) | 25–30% | Min. 25% |

| Hardness | ≤270 HB | Brinell |

| Density | 7.8 g/cm³ | 20°C |

4. Key Characteristics

-

Corrosion Resistance: Excellent resistance to chloride-induced stress corrosion cracking (SCC), pitting, and crevice corrosion, outperforming 316L in seawater and H₂S environments.

-

High Strength: Yield strength (~450 MPa) is ~2× higher than 316L, allowing reduced material use and cost savings.

-

Weldability: Compatible with TIG, MIG, and SMAW using ER2209/ER2594 filler wires; post-weld heat treatment not required.

-

Temperature Limits: Suitable for -50°C to 300°C; prolonged exposure >300°C may cause embrittlement.

-

Magnetic Properties: Exhibits ferromagnetism due to its dual-phase structure.

5. Standards & Equivalent Grades

Manufacturing Standards:

-

Pipe Production: EN 10216-5 (seamless pressure pipes).

-

General Material: ASTM A789/A790 (seamless pipes), ASTM A182 F51 (fittings).

Equivalent Grades:

| Region/System | Designation | |

|---|---|---|

| EN | 1.4462/X2CrNiMoN22-5-3 | |

| UNS | S31803, S32205 | |

| ASTM | F51, Duplex 2205 | |

| AFNOR | Z2CND22-5Az | |

| JIS | SUS329J3L |

6. Applications in Oil & Gas

1.4462 seamless pipes are ideal for critical hydrocarbon and corrosive media transport:

-

Offshore Platforms: Risers, subsea pipelines (NB100–NB400 sizes).

-

Downhole Equipment: Casing tubes, wellhead components (NB10–NB50).

-

Processing Units: Heat exchanger tubes, pressure vessels, and acid-resistant piping.

-

Midstream Infrastructure: Gathering pipelines, LNG plant piping.

7. Export Packaging & Transportation

-

Packaging:

-

Bundling: Pipes ≤159 mm OD, wrapped with waterproof material and steel straps.

-

Wooden Crates: For precision-finished pipes or small diameters (≤50 mm OD).

-

Surface Protection: Polished/annealed surfaces covered with plastic caps and anti-rust film.

-

-

Transport:

-

Shipping Terms: FOB, CFR, CIF (sea freight for bulk orders)

-

Lead Time: ~35 days from order confirmation

-

Certifications: EN 10204 3.1, PED 2014/68/EU, and NACE MR0175 for sour service

-

![]()

![]()

![]()

![]()