All Products

-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Alloy 904L / UNS N8904 Stainless Steel Pipes Tubing Seamless Steel Pipe for Chemical Area

Product Details

| Products | Stainless Steel Seamless Pipe | Grade | 904L |

|---|---|---|---|

| Diameter | DN10 - DN400 | Length | 6m Or Custom Cutting Any Length As Request |

| Standard | ASTM EN | Service | Cutting |

| Loading Port | Shanghai Port | Thickness | 4.0 - 50.0mm |

| Highlight | Alloy 904L stainless steel pipes,Seamless steel pipe for chemical area,UNS N8904 stainless steel tubing |

||

Product Description

Alloy 904L / UNS N8904 Stainless Steel Pipes Tubing Seamless Steel Pipe for Chemical Area

Products Specification

| Products Name | 904L Stainless Steel Seamless Pipe |

Grade: |

304 304L 309S 310S 314 315 316L 316Ti 317L 321 329 347H 410 2205 2507 S32760 904L 254SMO and equal grade in GB JIS EN DIN Standard |

| Standards: | ASTM A213M-94b ASTM A249M-94a ASTM A269-94a ASTM A312M-94b,ect. ASTM A790 |

| DIN 17456-85 DIN 17458-85 DIN 17459-92.ect | |

| JIS G3446-1994 JIS G3448-1997 JIS G3459-1997 JIS G3463-1994,ect. | |

| GB13296-1991 GB14975-2002 GB14976-2002,ect. | |

| Size: | ND5 - DN400 |

| Length: | 6m length or cutting any length as request |

| Applications: | fluid and gas transport, structure , boiler, heat exchanger, super heater |

Alloy 904L (UNS N8904) seamless steel pipes are high-performance materials engineered for extreme corrosion resistance in chemical processing and industrial environments. This super austenitic stainless steel offers a unique combination of mechanical strength, formability, and durability, making it ideal for applications involving aggressive acids, chlorides, and high-temperature conditions.

Key Parameters

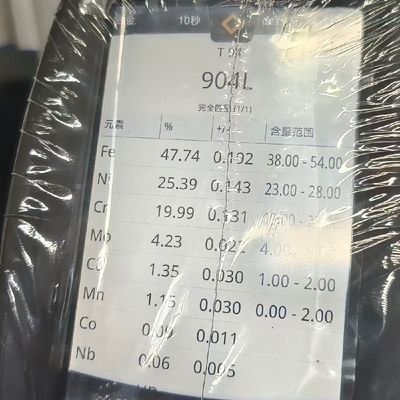

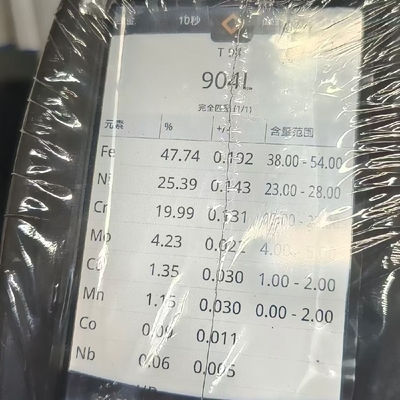

Chemical Composition of 904L Stainless Steel Pipe

- Carbon (C): ≤0.03%

- Chromium (Cr): 18.0–20.0%

- Nickel (Ni): 23.0–25.0%

- Molybdenum (Mo): 3.0–4.0%

- Copper (Cu): 4.0–5.0%

- Manganese (Mn): ≤2.00%

- Silicon (Si): ≤1.00%

- Phosphorus (P): ≤0.035%

- Sulfur (S): ≤0.030%

Mechanical Properties of 904L Stainless Steel Pipe

- Tensile Strength: ≥490 MPa

- Yield Strength (0.2% Offset): ≥216 MPa

- Elongation at Break: ≥35%

- Hardness: ≤230 HB

Physical Properties of 904L Stainless Steel Pipe

- Density: 8.24 g/cm³

- Melting Point: 1300–1390°C

- Thermal Conductivity: ~10 W/m·K (at 100°C)

- Maximum Service Temperature: 450°C

Standards of 904L Stainless Steel Pipe

Alloy 904L seamless pipes comply with international and industry standards, including:

- ASTM A312 / ASME SA-312 (seamless and welded pipes)

- EN 10216-5 (seamless steel tubes for pressure purposes)

- DIN 1.4539 (German standard equivalent)

- JIS SUS 890L (Japanese specification)

- ASTM B677 (seamless tubes for general corrosion resistance)

Performance Advantages of 904L Stainless Steel Pipe

-

Exceptional Corrosion Resistance

- Acidic Environments: Resistant to sulfuric, phosphoric, and acetic acids, even at high concentrations .

- Chloride Resistance: Strong immunity to pitting, crevice corrosion, and stress corrosion cracking (SCC) in chloride-rich media like seawater and brine .

- Passive Film Stability: High chromium and molybdenum content form a protective oxide layer, ensuring long-term durability .

-

Mechanical Integrity

- Retains strength and toughness across a wide temperature range, including cryogenic conditions .

- Excellent weldability with nickel-based fillers (e.g., Alloy 625) .

-

Formability

- Easy to fabricate into complex shapes without compromising corrosion resistance .

Equivalent Grades

- UNS N08904 (USA)

- EN 1.4539 / DIN 1.4539 (Europe)

- JIS SUS 890L (Japan)

- 00Cr20Ni25Mo4.5Cu (China)

- NAS 255 (Japan)

Packaging of 904L Stainless Steel Pipe

To ensure safe transportation and storage, Alloy 904L pipes are:

- Protected Internally/Externally: Coated with anti-corrosive oil or plastic film .

- Ends Sealed: Fitted with plastic caps to prevent debris ingress .

- Bundle Secured: Wrapped in waterproof paper or woven fabric, then strapped with steel bands or placed in wooden crates .

- Marine-Grade Packaging: Suitable for long-distance shipping, including ocean transport .

Applications of 904L Stainless Steel Pipe

Alloy 904L seamless pipes excel in demanding chemical and industrial sectors:

-

Chemical Processing

- Reactors, heat exchangers, and pipelines handling sulfuric acid, fertilizers, and organic solvents .

-

Oil & Gas

- Offshore platforms, seawater injection systems, and refinery equipment exposed to chloride and H₂S .

-

Pharmaceutical & Food Industries

- Sanitary pipelines and reactors requiring corrosion resistance and compliance with hygiene standards .

-

Environmental Engineering

- Flue gas desulfurization (FGD) systems, wastewater treatment plants, and acid recovery units .

-

Marine & Desalination

- Seawater desalination plants, condensers, and marine heat exchangers .

![]()

![]()

![]()

![]()

Recommended Products