All Products

-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

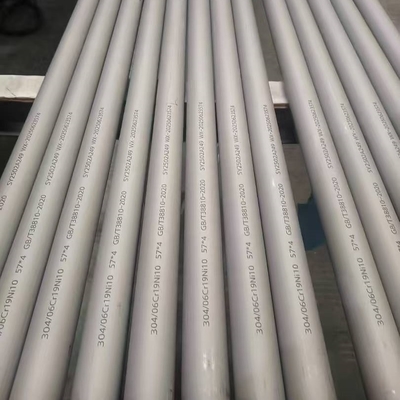

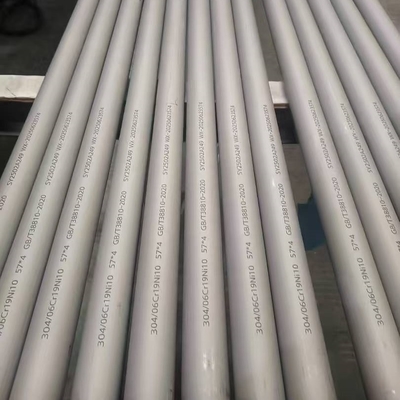

317L Stainless Steel Pipe Tube in 6m Length SS317L Alloy Seamless Pipe UNS S31703 Tubing

Product Details

| Products | Stainless Steel Seamless Pipe | Grade | 317L |

|---|---|---|---|

| Diameter | DN10 - DN400 | Length | 6m Or Custom Cutting Any Length As Request |

| Standard | ASTM EN | Service | Cutting |

| Loading Port | Shanghai Port | Thickness | 4.0 - 50.0mm |

| Highlight | 317L stainless steel seamless pipe,SS317L alloy tubing 6m length,UNS S31703 stainless steel pipe |

||

Product Description

317L Stainless Steel Pipe Tube in 6m Length SS317L Alloy Seamless Pipe UNS S31703 Tubing

Products Specification

| Products Name | 317L Stainless Steel Seamless Pipe |

Grade: |

304 304L 309S 310S 314 316L 316Ti 317L 321 329 347H 410 2205 2507 S32760 904L 254SMO and equal grade in GB JIS EN DIN Standard |

| Standards: | ASTM A213M-94b ASTM A249M-94a ASTM A269-94a ASTM A312M-94b,ect. |

| DIN 17456-85 DIN 17458-85 DIN 17459-92.ect | |

| JIS G3446-1994 JIS G3448-1997 JIS G3459-1997 JIS G3463-1994,ect. | |

| GB13296-1991 GB14975-2002 GB14976-2002,ect. | |

| Size: | ND5 - DN400 |

| Length: | 6m length or cutting any length as request |

| Applications: | fluid and gas transport, structure , boiler, heat exchanger, super heater |

317L stainless steel pipe is a high-performance austenitic stainless steel product known for its excellent corrosion resistance, high-temperature strength, and versatility. Below is a detailed introduction to 317L stainless steel seamless pipes, focusing on their parameters, standards, specifications, equivalent grades, characteristics, and applications.

Chemical Composition (Key Parameters)

The chemical composition of 317L stainless steel is strictly controlled to ensure its corrosion resistance and mechanical properties. The typical composition (by weight) is as follows:

- Carbon (C): ≤ 0.03% (low carbon content enhances weldability and resistance to intergranular corrosion)

- Chromium (Cr): 18.00 - 20.00% (primary element for oxidation and corrosion resistance)

- Nickel (Ni): 11.00 - 15.00% (stabilizes the austenitic structure, improving ductility and toughness)

- Molybdenum (Mo): 3.00 - 4.00% (greatly enhances resistance to pitting and crevice corrosion, especially in chloride environments)

- Manganese (Mn): ≤ 2.00%

- Silicon (Si): ≤ 1.00%

- Phosphorus (P): ≤ 0.045%

- Sulfur (S): ≤ 0.030%

Mechanical Properties

317L stainless steel pipes exhibit excellent mechanical performance, making them suitable for high-pressure and harsh environments:

- Tensile strength: ≥ 485 MPa

- Yield strength (0.2% offset): ≥ 170 MPa

- Elongation: ≥ 40% (high ductility for forming and fabrication)

- Hardness (Brinell): ≤ 217 HB

Standards

317L stainless steel seamless pipes are manufactured in compliance with international and industry standards to ensure quality and consistency. Common standards include:

- ASTM A312: Standard specification for seamless and welded austenitic stainless steel pipes.

- ASTM A269: Specification for seamless and welded austenitic stainless steel tubing for general service.

- ASME SA312 / SA269: Similar to ASTM standards, adopted for pressure vessel and boiler applications.

- EN 10216-5: European standard for seamless stainless steel tubes for pressure purposes.

Specifications (6m Length Focus)

The 6m length 317L seamless pipes are available in a range of dimensions to meet diverse application needs:

- Outer Diameter (OD): Typically from 6mm to 630mm (custom sizes available upon request).

- Wall Thickness (WT): From 0.8mm to 20mm (schedule 5S, 10S, 40S, 80S, etc., per ASTM standards).

- Length: Standard 6m (20 feet), with options for cut-to-length or longer lengths (e.g., 12m) based on requirements.

- Surface Finish: Annealed and pickled (AP), polished (BA/EP), or sandblasted, depending on application needs (e.g., hygiene-critical industries prefer polished surfaces).

Equivalent Grades

317L stainless steel is known by different designations across global standards. Its equivalent grades include:

- UNS S31703 (USA)

- EN 1.4438 (European Union)

- JIS SUS317L (Japan)

- GB 00Cr19Ni13Mo3 (China, obsolete; current equivalent may vary)

Key Characteristics

317L stainless steel pipes stand out due to the following properties:

- Superior Corrosion Resistance: The high molybdenum content (3-4%) makes 317L more resistant to pitting, crevice corrosion, and stress corrosion cracking than 304 or 316 stainless steel, especially in chloride-rich environments (e.g., seawater, chemical processing).

- Low Carbon Content: The "L" in 317L indicates low carbon, which minimizes carbide precipitation during welding, reducing the risk of intergranular corrosion.

- High-Temperature Performance: Maintains strength and oxidation resistance at elevated temperatures (up to 800°C), suitable for high-heat applications.

- Excellent Ductility and Weldability: Easily formed, bent, or welded using standard methods (e.g., TIG, MIG welding) without significant loss of properties.

- Hygienic and Non-Magnetic: Austenitic structure ensures non-magnetic behavior, and smooth surface finishes make it suitable for food, pharmaceutical, and sanitary applications.

Applications

Thanks to its robust properties, 317L stainless steel seamless pipes are widely used in the following industries:

- Chemical Processing: For transporting corrosive chemicals, acids (e.g., sulfuric acid), and solvents.

- Oil and Gas: In offshore platforms, subsea pipelines, and refineries, where resistance to saltwater and sour gases (H₂S) is critical.

- Pharmaceutical and Food Processing: Hygienic tubing for sterile fluid transfer, as it is easy to clean and resistant to bacterial growth.

- Desalination Plants: For handling brine and seawater during the desalination process.

- Power Generation: In boilers, heat exchangers, and flue gas desulfurization systems, where high temperatures and corrosion resistance are required.

- Marine Engineering: For shipbuilding components, such as seawater cooling systems and exhaust pipes.

![]()

![]()

![]()

![]()

Recommended Products