All Products

-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

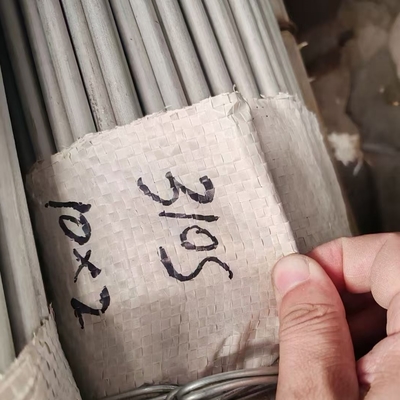

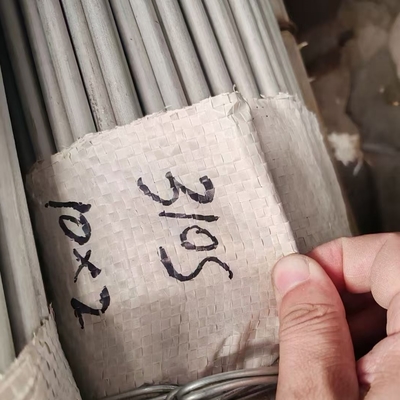

310S Stainless Steel Seamless Pipe DN10-DN300 SCH10S 40S 80S

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

xProduct Details

| Products | Stainless Steel Seamless Pipe | Grade | 310S / 1.4845 |

|---|---|---|---|

| Diameter | DN10 - DN400 | Length | 6m Or Custom Cutting Any Length As Request |

| Standard | ASTM EN | Service | Cutting |

| Loading Port | Shanghai Port | Thickness | 4.0 - 50.0mm |

| Highlight | 310S stainless steel seamless pipe,stainless steel pipe SCH10S,seamless pipe DN10-DN300 |

||

Product Description

DN10 - DN300 310S Stainless Steel Seamless Pipe SCH10S SCH40S SCH80S in 6m Length

Products Specification

| Products Name | 310S Stainless Steel Seamless Pipe |

Grade: |

304 304L 309S 310S 314 316L 316Ti 321 329 347H 410 2205 2507 S32760 904L 254SMO and equal grade in GB JIS EN DIN Standard |

| Standards: | ASTM A213M-94b ASTM A249M-94a ASTM A269-94a ASTM A312M-94b,ect. |

| DIN 17456-85 DIN 17458-85 DIN 17459-92.ect | |

| JIS G3446-1994 JIS G3448-1997 JIS G3459-1997 JIS G3463-1994,ect. | |

| GB13296-1991 GB14975-2002 GB14976-2002,ect. | |

| Size: | ND5 - DN400 |

| Length: | 6m length or cutting any length as request |

| Applications: | fluid and gas transport, structure , boiler, heat exchanger, super heater |

Introduction of 310S Stainless Steel Tube

Parameters

●

Chemical Composition:

○

Carbon (C): ≤0.08

○

Silicon (Si): ≤1.50

○

Manganese (Mn): ≤2.00

○

Phosphorus (P): ≤0.035

○

Sulfur (S): ≤0.030

○

Nickel (Ni): 19.00-22.00

○

Chromium (Cr): 24.00-26.00

●

Physical Properties:

○

Density: 7.98 kg/dm³

○

Melting Point: 1398-1453°C

○

Specific Heat Capacity (0-100°C): 0.5 kg/(kg·K)

○

Thermal Conductivity (100°C): 14.2 W/(m·K)

○

Thermal Conductivity (500°C): 18.6 W/(m·K)

○

Coefficient of Linear Expansion (0-100°C): 15.8×10⁻⁶/K

○

Coefficient of Linear Expansion (0-525°C): 17.5×10⁻⁶/K

○

Electrical Resistivity (20°C): 0.78 Ω·mm²/m

○

Young's Modulus (20°C): 200 GPa

○

Magnetic: Non-magnetic

●

Mechanical Properties:

○

Tensile Strength (RM): 520 MPa

○

Yield Strength (Rp0.2): 205 MPa

○

Elongation (A): 40%

○

Reduction of Area (Z): 50%

Standards

●

International Standards:

○

GB-T (China): Digital Grade: 2520, New Grade: 06Cr25Ni20, Old Grade: 0Cr25Ni20

○

ASTM (USA): A312 TP310S

○

SAE (USA): /

○

UNS (USA): 310

○

JIS (Japan): SUH310

○

DIN (Germany): 1.4841

○

EN (Europe): X15CrNiSi25-21

○

NF (France): Z12CN25-20

○

BS (UK): 310S31

○

Swedish: 142361

○

NTR (Norway): APFIS

Advantages

●

Excellent High-Temperature Performance: Capable of withstanding temperatures up to 1200°C, making it ideal for high-temperature applications.

●

Superior Oxidation and Corrosion Resistance: High chromium and nickel content provide excellent resistance to oxidation and corrosion, including resistance to sulfuric acid, phosphoric acid, and organic acids.

●

Good Creep Strength: Maintains strength and stability at high temperatures over extended periods.

●

Excellent Weldability: Low sulfur content ensures good weldability using various welding methods such as TIG, MIG, and arc welding.

●

High Strength and Durability: Combines high tensile strength with excellent durability, ensuring long-lasting performance in demanding environments.

Packaging

●

Standard Packaging: Tubes are typically packed in wooden crates or steel bundles to ensure protection during transportation.

●

Custom Packaging: Available upon request to meet specific customer needs, including anti-corrosion coatings and specialized labeling.

Applications

●

Petroleum and Chemical Industries: Used in heat exchangers, reactor internals, and piping systems due to its resistance to high temperatures and corrosive environments.

●

Power Generation: Ideal for boiler tubes, superheater tubes, and other components in power plants and gas turbines.

●

Food Processing: Suitable for heating and cooling systems in food processing equipment due to its hygiene and corrosion resistance.

●

Aerospace and Defense: Utilized in high-temperature components such as exhaust systems and structural parts.

●

Nuclear Industry: Applied in nuclear power plants for components that require high resistance to radiation and corrosion.

●

Furnace and Heating Applications: Commonly used in furnace tubes, burners, and combustion chambers due to its excellent(high-temperature performance).

310S stainless steel tubes offer a combination of high-temperature resistance, corrosion resistance, and mechanical strength, making them a preferred choice for a wide range of industrial applications.

![]()

![]()

![]()

![]()

Recommended Products