-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

310S Stainless Steel Seamless Pipe for High Temperature Applications

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Products | Stainless Steel Seamless Pipe | Grade | 310S / 1.4845 |

|---|---|---|---|

| Diameter | DN10 - DN400 | Length | 6m Or Custom Cutting Any Length As Request |

| Standard | ASTM EN | Service | Cutting |

| Loading Port | Shanghai Port | Thickness | 4.0 - 50.0mm |

| Highlight | 310S stainless steel seamless pipe,high temperature stainless steel pipe,seamless pipe for industrial use |

||

Heat Resistant 310S / 1.4845 Stainless Steel Seamless Pipe for Boiler and Heat Exchangers

Products Specification

| Products Name | 310S Stainless Steel Seamless Pipe |

Grade: |

304 304L 309S 310S 314 316L 316Ti 321 329 347H 410 2205 2507 S32760 904L 254SMO and equal grade in GB JIS EN DIN Standard |

| Standards: | ASTM A213M-94b ASTM A249M-94a ASTM A269-94a ASTM A312M-94b,ect. |

| DIN 17456-85 DIN 17458-85 DIN 17459-92.ect | |

| JIS G3446-1994 JIS G3448-1997 JIS G3459-1997 JIS G3463-1994,ect. | |

| GB13296-1991 GB14975-2002 GB14976-2002,ect. | |

| Size: | ND5 - DN400 |

| Length: | 6m length or cutting any length as request |

| Applications: | fluid and gas transport, structure , boiler, heat exchanger, super heater |

Introduction to 310S Stainless Steel Tubing

310S stainless steel tubing is a high-alloy austenitic stainless steel specifically designed for exceptional resistance to oxidation (scaling) and corrosion at elevated temperatures. It is the low-carbon version of the basic 310 alloy, which significantly enhances its suitability for high-temperature applications by minimizing carbide precipitation during welding or exposure in the critical temperature range (800°F - 1500°F / 427°C - 816°C).

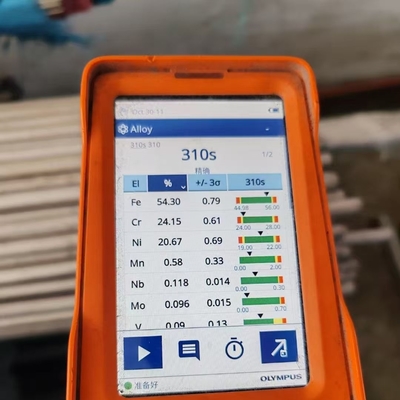

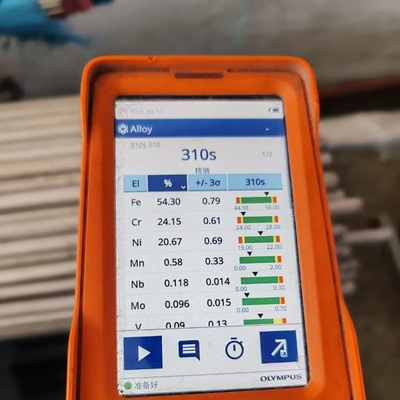

Key Parameters & Chemical Composition:

-

Common Grades: UNS S31008, AISI 310S, EN 1.4845

-

Chemical Composition (Typical Weight %):

-

Carbon (C): ≤ 0.08% (Low carbon for improved weldability & high-temp stability)

-

Chromium (Cr): 24.0 - 26.0% (Provides primary oxidation resistance)

-

Nickel (Ni): 19.0 - 22.0% (Stabilizes austenitic structure, enhances ductility & corrosion resistance)

-

Manganese (Mn): ≤ 2.00%

-

Silicon (Si): ≤ 1.50%

-

Phosphorus (P): ≤ 0.045%

-

Sulfur (S): ≤ 0.030%

-

Iron (Fe): Balance

-

-

Density: 7.98 g/cm³ (0.288 lb/in³)

-

Melting Point: ~1400°C - 1450°C (2550°F - 2640°F)

-

Continuous Service Temperature: Up to 1150°C (2100°F) in oxidizing atmospheres. Intermittent use up to 1035°C (1900°F).

-

Thermal Expansion: Relatively high (comparable to other austenitics like 304), ~16-18 μm/m·°C (20-100°C).

-

Thermal Conductivity: ~14 W/m·K (at 100°C).

-

Electrical Resistivity: ~0.85 μΩ·m.

-

Magnetic Properties: Essentially non-magnetic (austenitic structure).

Common Standards & Specifications:

310S tubing is manufactured to meet various international standards depending on dimensions, tolerances, testing, and intended use. Key standards include:

-

ASTM (American Society for Testing and Materials):

-

A213/A213M: Specification for Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger Tubes.

-

A269/A269M: Specification for Seamless and Welded Austenitic Stainless Steel Tubing for General Service.

-

A312/A312M: Specification for Seamless, Welded, and Heavily Cold Worked Austenitic Stainless Steel Pipes. (Often covers larger diameters/pipes).

-

A789/A789M: Specification for Seamless and Welded Ferritic/Austenitic Stainless Steel Tubing for General Service.

-

-

ASME (American Society of Mechanical Engineers): SA213, SA269, SA312, SA789 (Often identical to ASTM specs but adopted for Boiler & Pressure Vessel Code use).

-

EN (European Norm):

-

EN 10216-5: Seamless steel tubes for pressure purposes - Technical delivery conditions - Part 5: Stainless steel tubes.

-

EN 10296-2: Welded circular steel tubes for mechanical and general engineering purposes - Technical delivery conditions - Part 2: Stainless steel.

-

-

DIN (Deutsches Institut für Normung): DIN 17458 (Seamless circular tubes), DIN 17456 (Welded circular tubes).

-

JIS (Japanese Industrial Standards): JIS G 3463 (Stainless steel boiler and heat exchanger tubes), JIS G 3459 (Stainless steel pipes).

-

GOST (Russian Standards): GOST 9941 (Seamless hot-deformed tubes), GOST 11068 (Welded tubes).

Key Advantages:

-

Outstanding High-Temperature Oxidation Resistance: The high chromium (Cr) and nickel (Ni) content forms a stable, protective chromium oxide (Cr₂O₃) scale, preventing further oxidation even under severe cyclic heating conditions up to 1150°C (2100°F).

-

Excellent Carburization Resistance: Performs well in carburizing atmospheres compared to lower alloyed stainless steels.

-

Good Sulfidation Resistance: Offers reasonable resistance to sulfur-containing atmospheres at high temperatures.

-

Good Creep & Rupture Strength: Maintains strength better than standard austenitic grades (like 304/316) at sustained high temperatures.

-

Corrosion Resistance: Excellent general corrosion resistance in many aqueous environments (similar to 304/304L), and superior pitting/crevice corrosion resistance compared to 304 due to higher Cr & Ni. Resists nitric acid well.

-

Low Carbon Content (310S): Minimizes sensitization (chromium carbide precipitation at grain boundaries) during welding or high-temperature exposure, preventing intergranular corrosion and maintaining ductility. This is the key difference vs. 310.

-

Formability & Weldability: Good formability and weldability (using standard austenitic procedures like TIG, MIG, SAW), though its high strength can require more force for forming. Post-weld annealing is generally not required due to low carbon content.

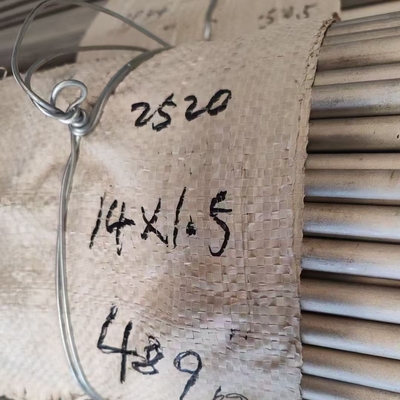

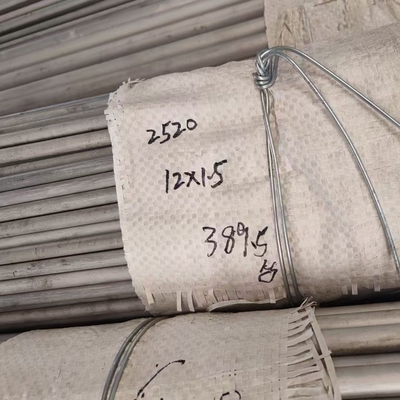

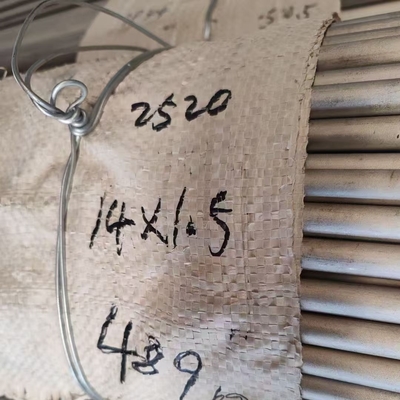

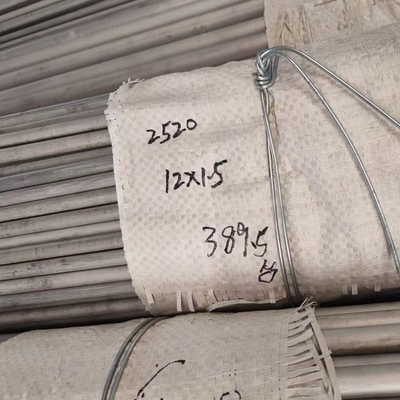

Typical Packaging:

Packaging aims to protect the tubing surface from damage, scratching, and corrosion during handling, storage, and transport. Common methods include:

-

Bundling: Tubes are securely strapped together (plastic or steel bands) into bundles.

-

End Protection: Plastic or metal end caps are often fitted to protect tube ends and threads (if present).

-

Wrapping: Bundles may be wrapped in:

-

Waterproof Paper / VCI Paper: Protects against moisture and provides basic physical protection. VCI (Vapor Corrosion Inhibitor) paper releases corrosion-inhibiting vapors.

-

Plastic Shrink Wrap / Polyethylene Film: Provides a moisture barrier and good physical protection.

-

Hessian / Burlap: Sometimes used over wrap for additional abrasion resistance (less common now).

-

-

Wooden Crates / Pallets: Bundles are placed on sturdy wooden pallets or enclosed within wooden crates for heavy loads, long-term storage, or demanding transport (especially sea freight). Wood must often comply with ISPM 15 for international shipping.

-

Identification: Each bundle or crate is clearly labeled with material grade (310S), size, length, heat number, quantity, standard, manufacturer, and other relevant order information.

Primary Applications:

310S tubing excels in environments involving high temperatures and corrosive atmospheres:

-

Furnace Components: Radiant tubes, muffles, retorts, combustion tubes, thermowells, burner nozzles, furnace conveyors, annealing covers.

-

Heat Exchangers & Boilers: Tubing for superheaters, reheaters, heat recovery systems, and other components in high-temperature, corrosive service (especially where oxidation resistance is paramount).

-

Chemical & Petrochemical Processing: Tubing in reactors, reformers, crackers, and piping systems handling hot corrosive gases, acids (like nitric), and catalysts.

-

Power Generation: Boiler tubes, superheater tubes, and other high-temperature components in fossil fuel and waste-to-energy plants.

-

Heat Treating Equipment: Fixtures, baskets, trays, and furnace internals exposed to repeated high temperatures.

-

Aerospace: Certain high-temperature exhaust components and engine parts.

-

Food Processing: Equipment requiring high-temperature sterilization and good corrosion resistance.

-

Kilns & Incinerators: Structural components and tubing exposed to high heat and combustion gases.

![]()

![]()

![]()

![]()