-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

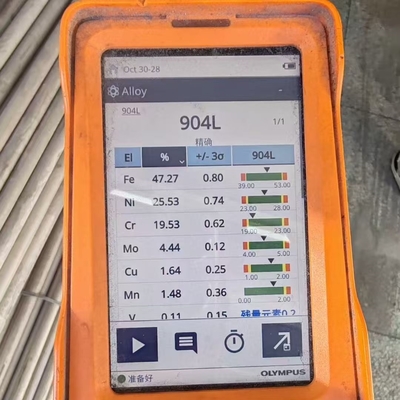

UNS N08904 / Alloy 904L Stainless Steel Seamless Pipe Pickling Annealing SS Pipes

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Products | Stainless Steel Seamless Pipe | Grade | 904L |

|---|---|---|---|

| Diameter | DN10 - DN400 | Length | 6m Or Custom Cutting Any Length As Request |

| Standard | ASTM EN | Service | Cutting |

| Loading Port | Shanghai Port | Thickness | 4.0 - 50.0mm |

| Highlight | SS Seamless Pipe,Annealing SS Seamless Pipe,Alloy 904L Seamless Pipe |

||

UNS N08904 / Alloy 904L Stainless Steel Seamless Pipe Pickling Annealing SS Pipes

Products Specification

| Products Name | 904L Stainless Steel Seamless Pipe |

Grade: |

304 304L 309S 310S 314 316L 316Ti 321 329 347H 410 2205 2507 S32760 904L 254SMO and equal grade in GB JIS EN DIN Standard |

| Standards: | ASTM A213M-94b ASTM A249M-94a ASTM A269-94a ASTM A312M-94b,ect. |

| DIN 17456-85 DIN 17458-85 DIN 17459-92.ect | |

| JIS G3446-1994 JIS G3448-1997 JIS G3459-1997 JIS G3463-1994,ect. | |

| GB13296-1991 GB14975-2002 GB14976-2002,ect. | |

| Size: | ND5 - DN400 |

| Length: | 6m length or cutting any length as request |

| Applications: | fluid and gas transport, structure , boiler, heat exchanger, super heater |

904L Stainless Steel Pipe: A Fusion of Corrosion Resistance and Mechanical Excellence

In the realm of high-performance engineering materials, 904L stainless steel pipe stands as a testament to metallurgical innovation. Designed for environments where conventional alloys falter, this austenitic stainless steel offers a unique blend of corrosion resistance, thermal stability, and mechanical robustness. Below, we explore its composition, properties, applications, and considerations through detailed text and structured tables, providing a comprehensive overview for industrial professionals and material engineers.

1. Chemical Composition: The Foundation of Corrosion Resistance

The superior performance of 904L originates from its carefully optimized chemical makeup. Unlike standard stainless steels (e.g., 304 or 316), 904L incorporates elevated levels of nickel (Ni), chromium (Cr), molybdenum (Mo), and copper (Cu), which synergistically enhance its resistance to aggressive chemicals. The low carbon content (<0.02%) minimizes carbide precipitation during welding, ensuring consistent corrosion resistance even after thermal processing.

| Element | Weight Percentage (%) | Role in Performance |

| Chromium (Cr) | 19.0–23.0 | Forms a protective Cr₂O₃ passive layer, resisting oxidation and general corrosion. |

| Nickel (Ni) | 23.0–28.0 | Enhances stability in austenitic structure, improves resistance to reducing acids and chloride stress corrosion. |

| Molybdenum (Mo) | 4.0–5.0 | Boosts resistance to pitting, crevice corrosion, and high-temperature oxidation in acidic media. |

| Copper (Cu) | 1.0–2.0 | Enhances resistance to non-oxidizing acids like sulfuric acid by promoting the formation of a protective copper-rich layer. |

| Carbon (C) | ≤0.02 | Minimizes intergranular corrosion by preventing carbide (Cr₂₃C₆) formation at grain boundaries during welding or heat treatment. |

| Manganese (Mn) | ≤2.0 | Stabilizes the austenitic structure and acts as a deoxidizer during manufacturing. |

| Silicon (Si) | ≤1.0 | Improves resistance to scaling at high temperatures and aids in casting. |

| Sulfur (S) | ≤0.03 | Maintains machinability while keeping impurities low. |

2. Mechanical Properties: Balancing Strength and Ductility

904L stainless steel pipe exhibits a favorable combination of strength, ductility, and formability, making it suitable for both structural and high-pressure applications. Its austenitic microstructure provides excellent toughness even at low temperatures, while its resistance to stress corrosion cracking (SCC) outperforms many lower-alloyed counterparts.

| Property | Value | Significance |

| Tensile Strength | 490–690 MPa | Ensures structural integrity under dynamic or static loads, such as in pipelines or pressure vessels. |

| Yield Strength (0.2% Offset) | ≥215 MPa | Indicates the stress at which permanent deformation begins, critical for design safety margins. |

| Elongation at Break | ≥35% | Demonstrates high ductility, enabling cold forming, bending, and welding without cracking. |

| Hardness (HB) | ≤220 | Balances machinability with resistance to wear in moderate-friction environments. |

| Impact Toughness (Charpy V, 20°C) | ≥200 J | Exhibits excellent toughness, making it suitable for cryogenic applications or areas prone to thermal shock. |

3. Physical Properties: Adaptability to Diverse Environments

904L’s physical characteristics allow it to perform reliably across a wide temperature range and in corrosive media. Its low thermal conductivity and moderate coefficient of thermal expansion reduce thermal stress in systems with frequent temperature fluctuations.

| Property | Value | Application Relevance |

| Density | 8.0 g/cm³ | Similar to other austenitic steels, impacting weight calculations for structural designs. |

| Thermal Conductivity | 11.2 W/m·K (at 100°C) | Low conductivity minimizes heat loss/gain in thermal transfer systems, though it requires attention in high-temperature insulation. |

| Coefficient of Thermal Expansion | 16.5 × 10⁻⁶/°C (20–100°C) | Matches well with common construction materials, reducing stress from thermal expansion/contraction. |

| Melting Range | 1350–1400°C | High melting point allows use in moderate-temperature processes without phase degradation. |

| Magnetic Permeability | Non-magnetic | Ideal for applications sensitive to magnetic interference, such as medical equipment or precision instruments. |

4. Manufacturing Processes: Precision for Performance

904L pipes are produced through two primary methods, each tailored to specific application needs:

- Seamless Pipes: Manufactured via hot piercing and cold drawing/rolling, these pipes have no weld seams, making them ideal for high-pressure (e.g., >100 bar) or high-integrity applications like oil & gas pipelines or chemical reactors.

- Welded Pipes: Fabricated from rolled sheets using TIG, laser, or plasma welding, welded pipes offer cost efficiency for lower-pressure systems (e.g., <50 bar). Post-weld solution annealing (1100–1150°C, rapid cooling) restores the uniform austenitic structure, eliminating intergranular corrosion risks.

Surface finishes, such as pickling or electro-polishing, are often applied to remove machining residues and enhance the passive oxide layer, critical for marine or pharmaceutical environments.

5. Industrial Applications: Where Durability is Non-Negotiable

904L’s resistance to strong acids, chlorides, and high salinity has cemented its role in industries where material failure could lead to catastrophic downtime or safety hazards.

| Industry | Application Scenarios | Challenging Media |

| Chemical Processing | Transport of sulfuric acid (5–50% concentration), phosphoric acid, formic acid, and organic solvents. | Reducing acids that attack conventional steels. |

| Oil & Gas | Offshore platform pipelines, downhole tubing, and refinery equipment. | Brine, hydrogen sulfide (H₂S), and CO₂-rich environments causing pitting and SCC. |

| Pulp & Paper | Bleaching lines (chlorine dioxide, hypochlorite) and digester systems. | Chloride-based bleaching agents and acidic pulping liquors. |

| Desalination | Seawater intake pipes, reverse osmosis (RO) membranes, and condenser tubes. | High-salinity water (30–40k ppm Cl⁻) and biocides like chlorine. |

| Pharmaceutical & Food | Process piping, storage tanks, and heat exchangers. | Citric acid, saline solutions, and cleaning agents (CIP/SIP processes). |

| Marine Engineering | Shipboard piping, coastal infrastructure, and seawater cooling systems. | Seawater erosion, chloride-induced corrosion, and biofouling. |

6. Advantages and Considerations

Key Advantages:

- Exceptional Corrosion Resistance: Outperforms 316L in reducing acids (e.g., sulfuric acid) and high-chloride environments.

- Weldability: Low carbon content and post-weld heat treatment ensure consistent performance after fabrication.

- Temperature Range: Reliable from cryogenic (-196°C) to moderate high temperatures (400°C).

- Design Flexibility: High ductility allows complex forming without compromising strength.

Considerations:

- Cost: Higher nickel and molybdenum content increase material costs (~3–4x more expensive than 304 stainless steel).

- Machinability: Its toughness can cause tool wear; requires carbide or cobalt-based tools with high cutting speeds and ample lubrication.

- Heat Transfer: Lower thermal conductivity may necessitate larger surface areas in heat exchanger designs.

7. Conclusion: A Premium Choice for Demanding Environments

904L stainless steel pipe is not just a material—it’s a solution for industries where compromise is not an option. Its carefully engineered composition, robust mechanical properties, and proven performance in hostile environments make it a cornerstone of modern industrial infrastructure. While its upfront cost and machining requirements demand careful consideration, the long-term benefits—reduced maintenance, extended service life, and operational reliability—justify its use in mission-critical applications. As global industries continue to push the boundaries of efficiency and sustainability, 904L remains a benchmark for high-performance corrosion-resistant piping.

By integrating advanced metallurgy with practical engineering, 904L exemplifies how material science can solve some of the most challenging environmental and operational hurdles, ensuring safety, efficiency, and longevity in even the harshest conditions.

![]()

![]()

![]()

![]()