All Products

-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

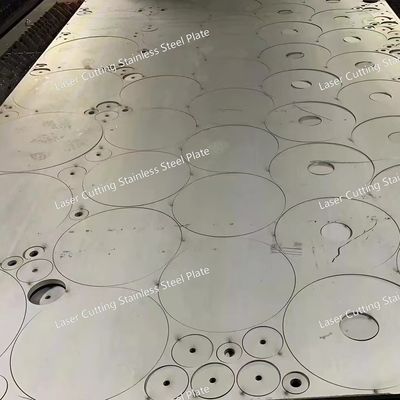

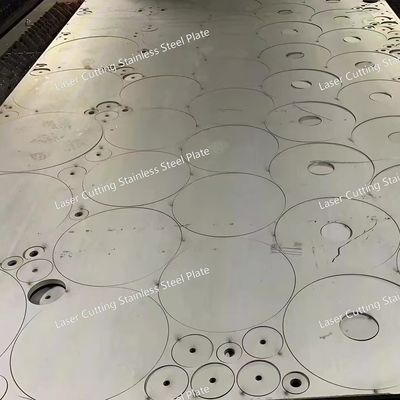

Laser Cutting Alloy 904L Stainless Steel Plate Thickness 3.0 - 20.0mm UNS N08904 Round Disc

| Place of Origin | China |

|---|---|

| Brand Name | TISCO BAOSTEEL |

| Certification | ISO |

| Model Number | 304 304L 316L 310S 321 2205 2507 904L 254SMO.etc |

| Minimum Order Quantity | 500 kgs |

| Price | 5000 - 7200 USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | T/T, Western Union |

| Supply Ability | 20Ton per week |

Product Details

| Products | Stainless Steel Plate | Grade | 304 304L 316L 310S 321 2205 2507 904L 254SMO.etc |

|---|---|---|---|

| Thickness | 0.6 - 30.0mm | Width | 1219mm 1500mm 1800mm 2000mm |

| Surface | NO.1 2B | Brand | BAOSTEEL TISCO |

| Standard | ASTM A240/240M | Loading Port | Shanghai Port |

| Highlight | Alloy 904L Stainless Steel Plate,UNS N08904 Stainless Steel Plate |

||

Product Description

Laser Cutting Alloy 904L Stainless Steel Plate Thickness 3.0 - 20.0mm UNS N08904 Round Disc

Products Specification

| Products Name | Laser Cutting Stainless Steel Plate |

| Main Grades | Stainless Steel J1, J2, J4, 201, 202, 301, 304, 304H, 304L, 309, 309S, 310, 310S, 316, 316L, 316TI, 317L, 321, 321H, 347, 409, 410, 410S, 420, 430, 441, 904L,630,631,254SMO,654SMO,253MA,2205,2507.etc |

| Thickness | 0.6 - 30.0mm |

| Width | 1250mm,1500mm ,1800mm,2000mm, or custom other size as request |

| Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, AS PER CUSTOMER’S REQUIREMENT |

| Service | Laser Cutting |

| Form | Plate / sheet |

| Cutting Shape | Round , Square, or any special shape as request |

| Test Certificate | Yes. |

| Finish | NO.1, 2B, 2D, 2H, 2R, No.4, HAIRLINE, SCOTCH BRITE, SATIN FINISH, NO.8, BA. |

| Brand | TISCO, LISCO,BAOSTEEL , POSCO, JISCO |

Laser Cutting of 904L Stainless Steel Plates

1. Overview of 904L Stainless Steel Plates

904L is a super austenitic stainless steel renowned for its exceptional resistance to corrosion, particularly in aggressive environments containing sulfuric acid, phosphoric acid, and chloride solutions. Its high nickel, chromium, and molybdenum content, combined with copper additions, make it a preferred material for demanding industrial applications.

1.1 Key Parameters

- Chemical Composition: Cr (19-23%), Ni (23-28%), Mo (4-5%), Cu (1-2%), C (≤0.02%), Si (≤1%), Mn (≤2%), P (≤0.03%), S (≤0.01%), N (≤0.1%). The synergistic effect of Cr, Ni, Mo, and Cu enhances resistance to both uniform and localized corrosion (e.g., pitting, crevice corrosion).

- Mechanical Properties:

- Tensile strength: 490-690 MPa

- Yield strength: ≥215 MPa

- Elongation: ≥35%

- Hardness: ≤230 HBW

- Corrosion Resistance: Excellent in reducing acids (e.g., sulfuric acid up to 50°C) and chloride-rich environments (pitting resistance equivalent number, PREN ≥40).

1.2 Common Sizes

904L stainless steel plates are available in dimensions suited for heavy-duty industrial use:

- Thickness: Typically 0.8 mm to 100 mm (custom thicknesses available for specialized equipment).

- Width & Length: Standard sizes include 1220×2440 mm, 1500×3000 mm, 2000×6000 mm. Larger or smaller sizes can be produced via cutting or rolling for specific projects.

1.3 Standards

904L plates adhere to strict international standards to ensure consistency in performance:

- ASTM A240/A240M (USA)

- EN 10088-4 (Europe)

- JIS G4305 (Japan)

- GB/T 3280 (China)

1.4 Key Characteristics

- Superior Corrosion Resistance: Outperforms standard austenitic steels (e.g., 316L) in harsh environments, including sulfuric acid, acetic acid, and seawater, due to its high Mo and Cu content.

- Good Mechanical Properties: Balances strength and ductility, allowing for forming, bending, and welding without compromising integrity.

- Resistance to Stress Corrosion Cracking (SCC): Performs well in chloride-induced SCC scenarios, critical for offshore or chemical processing applications.

- Weldability: Can be welded using TIG or MIG methods with matching fillers, though low carbon content minimizes carbide precipitation.

1.5 Applications

904L stainless steel plates are indispensable in industries requiring extreme corrosion resistance:

- Chemical Processing: Storage tanks, pipelines, and reactors handling sulfuric acid, phosphoric acid, and organic acids.

- Oil & Gas: Offshore platforms, subsea equipment, and desalination plants (resistant to seawater and brines).

- Pharmaceuticals: Equipment for sterile processing and acid-based cleaning solutions.

- Food & Beverage: Machinery for acidic food processing (e.g., citrus juices) to prevent contamination.

- Pollution Control: Scrubbers and waste treatment systems handling corrosive effluents.

2. Laser Cutting of 904L Stainless Steel Plates

Laser cutting, utilizing a focused high-energy laser beam, is an ideal method for shaping 904L plates, even with their high alloy content, due to its precision and minimal impact on material properties.

2.1 Advantages of Laser Cutting

- Exceptional Precision: Achieves tight tolerances (±0.03 mm) and smooth, burr-free edges (Ra ≤10 μm), critical for sealing surfaces in chemical tanks or pressure vessels.

- Minimal Heat-Affected Zone (HAZ): Laser cutting limits HAZ to 0.05-0.3 mm, preserving 904L’s corrosion resistance (unlike plasma cutting, which may expand HAZ and compromise anti-corrosive properties).

- Complex Geometry Handling: Easily cuts intricate shapes (e.g., custom flanges, precision slots, or curved profiles) that are difficult with mechanical methods like milling or sawing.

- Non-Contact Process: Eliminates tool wear and material deformation, ensuring consistent quality across large batches—vital for 904L, a high-cost material where waste must be minimized.

- Efficiency: Faster than waterjet cutting for thin to medium thicknesses (0.8-25 mm), reducing lead times for both prototypes and mass production.

- Narrow Kerf: A kerf width of 0.1-0.4 mm minimizes material loss, optimizing cost-efficiency for expensive 904L plates.

2.2 Processing Range

Laser cutting for 904L stainless steel plates is effective within the following parameters:

- Thickness: 0.8 mm to 30 mm (using fiber lasers with 6-15 kW power; thicker plates may require higher power or oxygen assist gas to enhance melting).

- Size Capacity: Handles large plates up to 6000×2000 mm, with automated systems enabling continuous processing for industrial-scale orders.

- Design Flexibility: Supports 2D cutting of any CAD-designed shape, from simple rectangles to complex components like chemical reactor internals or offshore flange patterns.

![]()

![]()

![]()

![]()

Recommended Products