All Products

-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

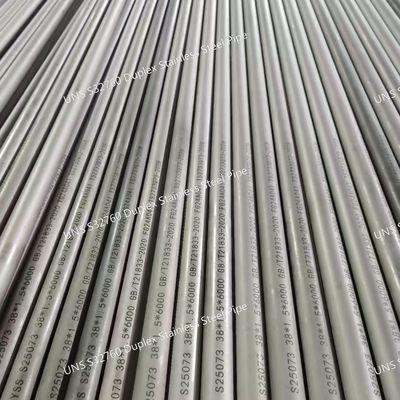

Super Duplex UNS S32760 / EN 1.4501 Stainless Steel Seamless Pipe

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

xProduct Details

| Products | Stainless Steel Seamless Pipe | Grade | S32760 |

|---|---|---|---|

| Diameter | DN10 - DN400 | Length | 6m Or Custom Cutting Any Length As Request |

| Standard | ASTM EN | Service | Cutting |

| Loading Port | Shanghai Port | Thickness | 4.0 - 50.0mm |

Product Description

Super Duplex UNS S32760 / EN 1.4501 Stainless Steel Seamless Pipe

Products Specification

| Products Name | s32760 Duplex Stainless Steel Seamless Pipe |

Grade: |

304 304L 309S 310S 314 316L 316Ti 321 329 347H 410 2205 2507 S32760 904L 254SMO and equal grade in GB JIS EN DIN Standard |

| Standards: | ASTM A213M-94b ASTM A249M-94a ASTM A269-94a ASTM A312M-94b,ect. |

| DIN 17456-85 DIN 17458-85 DIN 17459-92.ect | |

| JIS G3446-1994 JIS G3448-1997 JIS G3459-1997 JIS G3463-1994,ect. | |

| GB13296-1991 GB14975-2002 GB14976-2002,ect. | |

| Size: | ND5 - DN400 |

| Length: | 6m length or cutting any length as request |

| Applications: | fluid and gas transport, structure , boiler, heat exchanger, super heater |

Introduction to S32760 Duplex Stainless Steel Pipe

S32760 duplex stainless steel pipe, also known as super duplex stainless steel, is a high-performance alloy renowned for its exceptional combination of strength, corrosion resistance, and durability. Here’s a detailed overview:

Chemical Composition

The key elements of S32760 include:

- Chromium (Cr): 24–26%

- Nickel (Ni): 6–8%

- Molybdenum (Mo): 3–5%

- Tungsten (W): 0.5–1%

- Nitrogen (N): 0.2–0.3%

- Carbon (C): ≤0.03%

- Other elements: Iron (Fe) as the base, with small additions of copper (Cu) and manganese (Mn).

This composition creates a balanced duplex microstructure of austenite and ferrite phases, enhancing its mechanical and corrosion-resistant properties.

Mechanical Properties

- Tensile Strength: ≥750 MPa

- Yield Strength: ≥550 MPa

- Elongation: ≥25%

- Hardness (HB): ≤310

- Density: ~8.0 g/cm³

These properties make S32760 pipes suitable for high-pressure and high-stress applications, far exceeding those of standard stainless steels like 304 or 316.

Corrosion Resistance

S32760 excels in resisting:

- Pitting and Crevice Corrosion: Due to high Cr, Mo, and W content, it performs well in chloride-rich environments (e.g., seawater, brine).

- Stress Corrosion Cracking (SCC): The duplex structure and nitrogen addition significantly reduce SCC risk compared to austenitic steels.

- General Corrosion: Resistant to acids, alkalis, and organic solvents, making it ideal for chemical processing.

Applications

S32760 duplex stainless steel pipes are widely used in:

- Oil and Gas Industry: Offshore pipelines, subsea equipment, and chemical injection systems.

- Chemical and Petrochemical Plants: Reactors, heat exchangers, and pipelines for corrosive media.

- Marine Engineering: Shipbuilding, seawater desalination systems, and coastal infrastructure.

- Power Generation: Flue gas desulfurization (FGD) systems and high-temperature components.

- Food and Pharmaceutical Industries: Equipment requiring high hygiene and corrosion resistance.

Advantages

- High Strength-to-Weight Ratio: Reduces material usage and costs in structural designs.

- Superior Durability: Long service life in harsh environments, minimizing maintenance.

- Weldability: Can be welded using standard techniques, though post-weld heat treatment is sometimes recommended to optimize properties.

- Resistance to High Temperatures: Maintains stability in applications up to ~300°C.

Standards and Specifications

S32760 conforms to international standards such as:

- ASTM A790 (USA)

- EN 10216-5 (Europe)

- ISO 1127 (International)

Manufacturers typically provide certificates verifying chemical composition, mechanical properties, and non-destructive testing (NDT) results.

Comparison with Other Duplex Steels

| Grade | Strength | Corrosion Resistance | Main Applications |

|---|---|---|---|

| S31803 (2205) | Moderate | Good in mild chloride environments | General industrial use |

| S32760 | High | Excellent in severe chloride and acidic conditions | Offshore, chemical processing |

| S32750 (2507) | Very high | Similar to S32760 but with slightly lower W content | Demanding marine and oil & gas |

Conclusion

S32760 duplex stainless steel pipe stands out as a premium material for critical applications where extreme corrosion resistance and high strength are non-negotiable. Its unique microstructure and alloy composition make it a preferred choice for industries operating in challenging environments, ensuring reliability and cost-effectiveness over the long term.

Recommended Products