-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

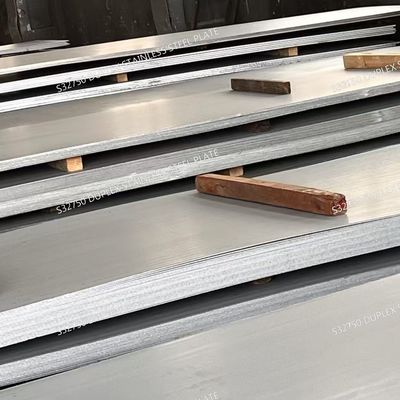

S32750 Stainless Steel Plate High Strength Superior Pitting Resistance Alloy 2507 NO.1 Surface Grade

| Place of Origin | China |

|---|---|

| Brand Name | TISCO BAOSTEEL |

| Certification | ISO |

| Model Number | S32750 / 2507 |

| Minimum Order Quantity | 500 kgs |

| Price | 5000 - 7200 USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | T/T, Western Union |

| Supply Ability | 20Ton per week |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Products | Stainless Steel Plate | Grade | S32750 / 2507 |

|---|---|---|---|

| Thickness | 1.0 - 80.0mm | Width | 1500mm 1800mm 2000mm |

| Surface | NO.1 | Brand | BAOSTEEL TISCO |

| Standard | ASTM A240/240M | Loading Port | Shanghai Port |

| Highlight | S32750 Stainless Steel Plate,Superior Pitting Resistance Steel Plate,High Strength Stainless Steel Plate |

||

S32750 Stainless Steel Plate High Strength and Superior Pitting Resistance Alloy 2507

Products Specification

| Products Name | S32750 Duplex Stainless Steel Plate |

| Main Grades | Stainless Steel J1, J2, J4, 201, 202, 301, 304, 304H, 304L, 309, 309S, 310, 310S, 316, 316L, 316TI, 321, 321H, 347, 409, 410, 410S, 420, 430, 441, 904L,630,631,254SMO,253MA,2205,2507.etc |

| Thickness | 3.0 - 80.0mm |

| Width | 1250mm,1500mm ,1800mm,2000mm, or custom other size as request |

| Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, AS PER CUSTOMER’S REQUIREMENT |

| Type of Material | Laser Cutting |

| Form | Plate / coil |

| Test Certificate | Yes. |

| Finish | NO.1, 2B, 2D, 2H, 2R, No.4, HAIRLINE, SCOTCH BRITE, SATIN FINISH, NO.8, BA. |

| Brand | TISCO, LISCO,BAOSTEEL , POSCO, JISCO |

Overview

SAF 2507 (UNS S32750, EN 1.4410) is a super duplex stainless steel characterized by a balanced microstructure of approximately 50% ferrite (α) and 50% austenite (γ). This dual-phase structure combines exceptional strength, superior corrosion resistance, and excellent toughness, making it ideal for demanding industrial applications in aggressive environments136.

Key Features

-

Exceptional Corrosion Resistance

-

PRE (Pitting Resistance Equivalent) > 43: Outstanding resistance to pitting, crevice corrosion, and stress corrosion cracking (SCC) in chloride-rich environments (e.g., seawater, chemical solutions)1710.

-

Superior to 904L and comparable to 6% Mo super-austenitic grades (e.g., 254SMO)13.

-

Resists diluted sulfuric/hydrochloric acids and organic acids (e.g., formic, acetic acid)78.

-

-

High Mechanical Strength

-

Yield Strength ≥ 550 MPa, Tensile Strength: 795–1000 MPa (twice the strength of standard austenitic steels like 316L)1810.

-

Elongation: ≥25%, Hardness: ≤ 310 HB28.

-

-

Thermal Stability

-

Low thermal expansion coefficient and high thermal conductivity410.

-

Temperature Limit: Prolonged exposure above 570°F (300°C) may reduce toughness; optimal use below this threshold410.

-

Chemical Composition (wt.%)

| Element | Cr | Ni | Mo | N | Mn | C ≤ | Si ≤ | Fe |

|---|---|---|---|---|---|---|---|---|

| Content | 24.0–26.0 | 6.0–8.0 | 3.0–4.0 | 0.24–0.32 | ≤1.2 | 0.03 | ≤0.8 | Balance |

| Trace elements: P ≤ 0.035%, S ≤ 0.020%, Cu ≤ 0.50%1410. |

Physical Properties

-

Density: 8.03 g/cm³

-

Melting Point: 1300–1390°C

-

Magnetism: Non-magnetic (annealed condition)48.

Corrosion Resistance Highlights

-

Stress Corrosion Cracking (SCC): Excellent resistance in chloride environments17.

-

Intergranular Corrosion: Low carbon content (≤0.03%) minimizes carbide precipitation risks78.

-

Erosion-Corrosion & Fatigue: High resistance in marine and acidic media110.

Heat Treatment & Fabrication

-

Solution Annealing: 1000–1052°C (rapid air/water cooling) to maintain 50/50 α/γ phase balance28.

-

Welding:

-

Recommended Filler: ER2594 wire or E2594 electrode28.

-

Control heat input to avoid detrimental phase formation (e.g., sigma, chi phases)68.

-

Applications

SAF 2507 plates are widely used in:

-

Oil & Gas: Offshore platforms, heat exchangers, seawater piping, subsea components17.

-

Chemical Processing: Reactors, pressure vessels, acid-handling equipment38.

-

Desalination Plants: High-pressure RO systems, seawater pipelines15.

-

Pollution Control: Flue gas desulfurization (FGD) scrubbers, absorber towers38.

-

Marine & Structural: Propeller shafts, corrosion-resistant structural parts310.

Available Plate Specifications

| Parameter | Range |

|---|---|

| Thickness | 0.3 mm – 350 mm |

| Width | Standard: 1219–1500 mm |

| Surface Finish | 2B, polished, or customized |

| Standards | ASTM A240, ASME SA-182 |

Custom sizes and processing (e.g., cutting, grinding) available189.

Key Considerations

-

Avoid High Temperatures: Prolonged use >300°C degrades toughness410.

-

Cost Efficiency: Higher initial cost than 2205 duplex steel but cost-effective vs. nickel alloys18.

-

Certifications: Supplied with mill test reports (MTRs) per ASTM standards89.

Why Choose SAF 2507 Plates?

-

Weight Savings: High strength allows thinner sections vs. conventional steels610.

-

Longevity: Nano-scale Cr-Mo-N segregation at phase boundaries enables self-repairing passive films6.

-

Extreme Environment Suitability: Validated for 3000m deep-sea pressure and hydrogen-rich conditions6.

![]()

![]()

![]()

![]()