All Products

-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

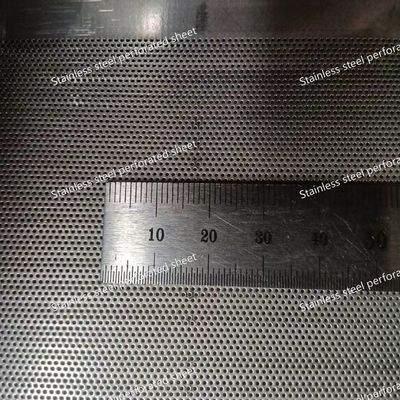

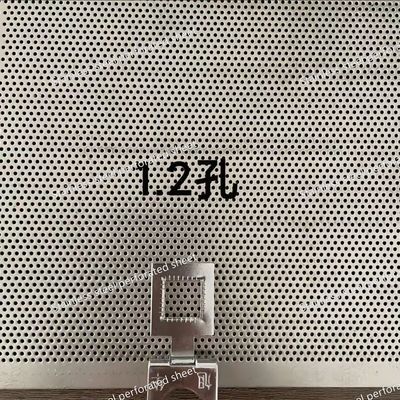

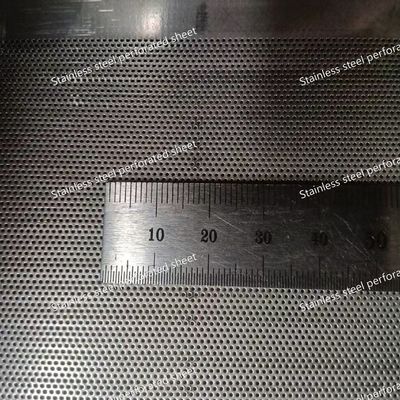

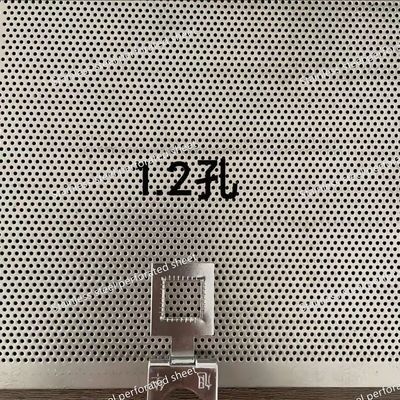

Alloy 904L / UNS N08904 Stainless Steel Perforated Sheets Thickness 0.3 - 3.0mm With Hole Diameter 0.1-20.0mm

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

xProduct Details

| Highlight | Alloy 904L Stainless Steel Perforated Sheets,UNS N08904 Stainless Steel Perforated Sheets,Stainless Steel Perforated Sheets Thickness 0.3mm |

||

|---|---|---|---|

Product Description

Alloy 904L / UNS N08904 Stainless Steel Perforated Sheets Thickness 0.3 - 3.0mm With Hole Diameter 0.1-20.0mm

Products Specification:

| Product Name | Stainless Steel Perforated Sheet |

| Grade | 201 304L 304 309S 310S 321 317L 316L 316Ti 2205 2507 904L 254SMO 409L 436 441.etc |

| Hole Shape | Diamond, Round, Square, Hexagon |

| Size for mesh panel | 1000*2000mm, 1200*2400mm, 1250mm*2500mm, as customized |

| Hang Thickness | 0.3mm-10mm |

| Hole Size | Diameter 0.1 - 10.0mm |

| Techniqe | Perforated |

| Application | Office Ceiling, Building protection, Indoor decoration |

Product Overview

Our 904L stainless steel perforated plates are skillfully manufactured, taking full advantage of the exceptional properties of 904L, a high - alloy austenitic stainless steel. These plates feature precisely punched holes in various patterns, providing customized solutions that meet the diverse requirements of multiple industries, blending functionality with excellent corrosion resistance.

Parameters

- Material Composition: 904L stainless steel is composed of approximately 19% chromium, 23% nickel, 4.5% molybdenum, and 1% copper. This unique chemical composition endows it with outstanding resistance to general corrosion, pitting, and crevice corrosion in a wide range of acidic environments.

- Tensile Strength: ≥490 MPa, ensuring reliable mechanical strength for various applications.

- Yield Strength: ≥220 MPa, offering stable structural performance under load.

- Elongation: ≥35%, providing good formability during the manufacturing process while maintaining structural integrity.

- Density: 8.0 g/cm³, contributing to a balance between strength and weight.

Specifications

- Thickness: Available in a range from 0.5mm to 8.0mm, catering to different load - bearing and design needs of projects.

- Hole Patterns: A diverse selection of patterns is provided, including round holes (diameter 1mm - 60mm), square holes (side length 2mm - 60mm), slot holes (width 2mm - 15mm, length customizable), hexagonal holes, and custom - designed patterns upon request.

- Plate Sizes: Standard sizes vary from 1000mm×2000mm to 1500mm×6000mm. Non - standard sizes can be custom - fabricated according to specific project requirements.

- Surface Finish: Options include 2B finish (smooth cold - rolled), BA finish (bright annealed), mirror finish, and hairline finish, enhancing both the aesthetic appearance and practical functionality of the plates, such as reducing the adhesion of dirt and facilitating cleaning.

Advantages

- Exceptional Corrosion Resistance: 904L stainless steel demonstrates excellent resistance to a wide variety of corrosive media, especially in sulfuric acid - containing environments, as well as in phosphoric acid, nitric acid, and chloride - containing solutions. It outperforms many other stainless steel grades in highly corrosive conditions, making it suitable for applications where long - term exposure to aggressive chemicals is expected.

- Good Mechanical Properties: With a balanced combination of strength and ductility, 904L stainless steel perforated plates can withstand mechanical stresses and deformations without cracking or breaking easily. This ensures the durability and reliability of the plates in different working conditions.

- High - Temperature Resistance: It maintains good mechanical properties and corrosion resistance at elevated temperatures, making it applicable for use in equipment and structures operating in high - temperature environments, such as heat exchangers and industrial furnaces.

- Easy Fabrication and Welding: Despite its high - alloy content, 904L stainless steel has good fabricability and weldability. It can be easily formed into various shapes and sizes, and welded using common welding methods, which simplifies the manufacturing and installation processes for different projects.

Corresponding Standards and Grades

- Standards: Complies with international standards such as ASTM A240/A240M (specification for chromium and chromium - nickel stainless steel plates, sheets, and strips for pressure vessels and general applications), EN 10088 - 2 (European standard for stainless steels), and JIS G4305 (Japanese industrial standard for cold - rolled stainless steel sheets and strips).

- Grades: Internationally recognized grades include ASTM N08904, EN 1.4539, and JIS SUS890L.

Applications

- Chemical Industry: Widely used in chemical reactors, storage tanks, pipelines, and heat exchangers for handling various corrosive chemicals, such as sulfuric acid, phosphoric acid, and chloride - based solutions. Its excellent corrosion resistance ensures the safe and long - term operation of chemical processing equipment.

- Petrochemical Industry: Applied in equipment and facilities in oil refineries and gas processing plants, where it can resist the corrosion caused by crude oil, refined products, and chemical additives, enhancing the reliability and lifespan of petrochemical infrastructure.

- Wastewater Treatment: Used in wastewater treatment plants for components that come into contact with corrosive wastewater, such as treatment tanks, drainage pipes, and filtration systems. 904L stainless steel's resistance to corrosion from various pollutants in wastewater helps maintain the functionality of the treatment facilities.

- Food and Beverage Industry: Suitable for use in food processing equipment, storage containers, and conveyor systems, as it meets the strict hygiene requirements of the industry and is resistant to corrosion from food acids and cleaning agents, ensuring food safety and equipment durability.

- Marine and Offshore Applications: Although not as chloride - resistant as some duplex stainless steels in extreme marine environments, 904L stainless steel is still used in certain marine applications, such as parts of ships and offshore structures where it can provide good corrosion resistance against seawater and marine atmospheres, reducing maintenance costs and extending the service life of components.

![]()

![]()

![]()

![]()

Recommended Products