All Products

-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

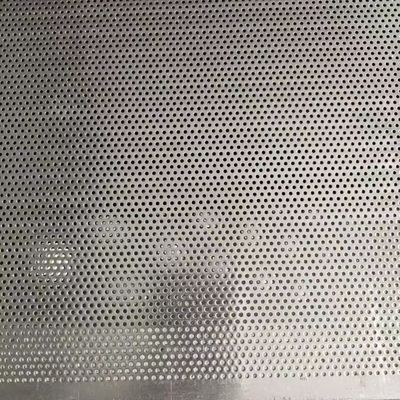

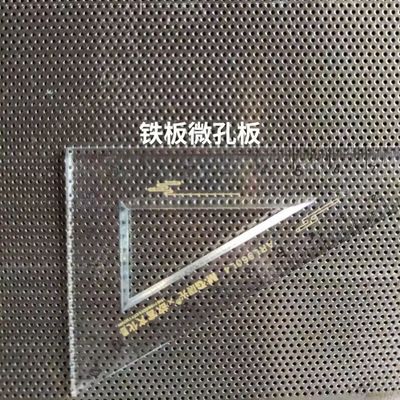

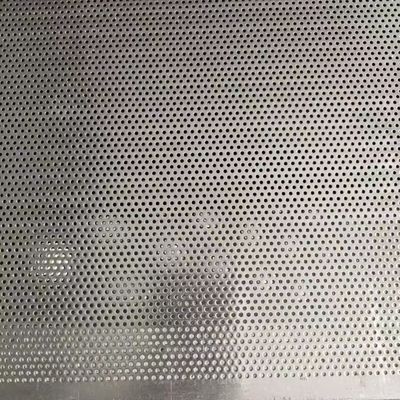

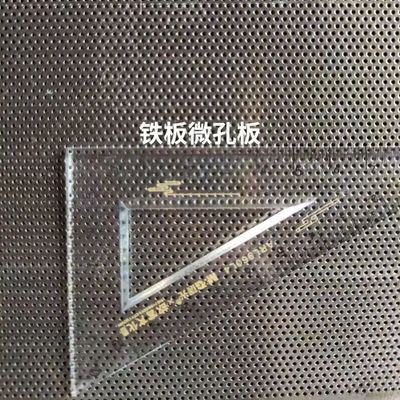

Premium 304 Stainless Steel Micro-Holes Sheets With Precise Micropores Corrosion Resistant High Durability

| Place of Origin | China |

|---|---|

| Brand Name | TISCO |

| Certification | ISO |

| Model Number | 304 316L 430 410S.etc |

| Minimum Order Quantity | 500 kgs |

| Price | 2100 - 3200 USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | T/T, Western Union, L/C |

| Supply Ability | 10 Ton per week |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

xProduct Details

| Products | Stainless Steel Micro Perforated Sheet | Grade | 304 201 316L 430 410S.etc |

|---|---|---|---|

| Hole Diameter | 0.1 - 10.0mm | Size | 1000*2000mm 1219*2438mm 1500*3000mm |

| Thickness | 0.3 - 3.0mm | Type | Cold Rolled |

| Surface | 2B | Application | Industrial |

| Packing | Wooden Pallets | ||

| Highlight | 304 Stainless Steel Micro-Holes Sheets,Corrosion Resistant Stainless Steel Sheet,Precise Micropores Stainless Steel Sheet |

||

Product Description

Premium 304 Stainless Steel Micro-Holes Sheets With Precise Micropores Corrosion Resistant & High Durability

Products Specification:

| Product Name | Stainless Steel Perforated Sheet |

| Grade | 201 304L 304 309S 310S 321 317L 316L 316Ti 2205 2507 904L 254SMO 409L 436 441.etc |

| Hole Shape | Diamond, Round, Square, Hexagon |

| Size for mesh panel | 1000*2000mm, 1200*2400mm, 1250mm*2500mm, as customized |

| Hang Thickness | 0.3mm-10mm |

| Hole Size | Diameter 0.1 - 10.0mm |

| Techniqe | Perforated |

| Application | Office Ceiling, Building protection, Indoor decoration |

304 Stainless Steel Perforated Mesh Sheet Product Information

1. Basic Parameters

Our 304 stainless steel perforated mesh board is available in a wide range of specifications. The standard board sizes vary from small pieces suitable for detailed applications, starting at 300mm×300mm, to large - scale boards up to 2500mm×6000mm, meeting diverse project demands. The thickness of the board ranges from 0.5mm to 5mm, providing options for different load - bearing and durability requirements. As for the holes, a vast array of shapes can be produced, including round, square, rectangular, triangular, hexagonal, and custom - designed shapes. Hole diameters for round holes typically range from 0.5mm to 100mm, while side lengths for square and rectangular holes can be customized according to specific needs. The hole pitch (distance between holes) can also be precisely adjusted, with common ranges from 1mm to 100mm, enabling control over the open area percentage of the mesh board, which usually ranges from 10% to 70%.

2. Material Characteristics

Constructed from high - grade 304 stainless steel, which conforms to international standards such as ASTM A240/A240M - 22 and EN 10088 - 2. This material is an austenitic stainless steel alloy, containing approximately 18% chromium and 8% nickel. The high chromium content forms a passive oxide film on the surface, which provides exceptional corrosion resistance, protecting the board from rusting in various environments, including those with moisture, mild chemicals, and atmospheric pollutants. The nickel addition enhances the material's ductility, toughness, and resistance to stress corrosion cracking, ensuring the board maintains its structural integrity under different conditions.

3. Manufacturing Process

The production of our 304 stainless steel perforated mesh sheet employs advanced punching techniques. High - precision CNC punching machines are utilized to ensure accurate hole positioning and consistent hole quality. The punching process can be adjusted according to the specific requirements of hole shape, size, and density. For complex hole patterns, computer - aided design (CAD) software is used to create detailed punching templates, which are then translated into instructions for the punching machines. After punching, the edges of the board are carefully deburred to remove any sharp edges, ensuring safety during handling and installation. Additionally, for some special requirements, processes such as bending, rolling, and welding can be applied to further shape the mesh board.

4. Performance Advantages

- High Strength and Durability: Due to the inherent strength of 304 stainless steel, the perforated mesh board exhibits excellent load - bearing capacity. It can withstand significant mechanical stress, making it suitable for applications where structural stability is crucial, such as industrial platforms and heavy - duty partitions.

- Corrosion and Rust Resistance: As mentioned, the unique alloy composition provides superior protection against corrosion. This makes the board ideal for outdoor applications, coastal areas, and industries with high humidity or exposure to chemicals, ensuring a long service life with minimal maintenance.

- Ventilation and Filtration: The precisely designed hole patterns allow for efficient air and fluid flow, making it an excellent choice for ventilation systems, air filters, and sieving applications in industries like food processing, pharmaceuticals, and chemical engineering.

- Aesthetic Appeal: The clean and uniform appearance of the perforated pattern, combined with the sleek surface of stainless steel, gives the board an attractive look. It can be used in architectural applications for decorative facades, interior partitions, and furniture design, adding a modern and stylish touch to the space.

5. Surface Treatments

To further enhance the performance and appearance of the 304 stainless steel perforated mesh board, various surface treatments are available:

- Polishing: A polishing treatment can create a mirror - like finish, significantly improving the aesthetic appeal of the board. It also makes the surface easier to clean and more resistant to dirt and stains, which is beneficial for applications in the food and medical industries.

- Brushing: Brushed finish gives the board a textured, satin - like appearance. This treatment can hide minor scratches and fingerprints, making it a popular choice for architectural and decorative applications where a more understated look is desired.

- Powder Coating: Powder coating provides a wide range of color options, enhancing the board's visual appeal while also adding an extra layer of protection against corrosion and abrasion. It is suitable for both indoor and outdoor applications where color - matching or additional protection is required.

- Anodizing: Although less common for stainless steel, anodizing can be applied to create a hard, durable oxide layer on the surface, improving wear resistance and providing a unique color finish.

6. Application Fields

- Architecture and Construction: Used as building facades, sunscreens, balcony guards, interior partitions, and decorative panels, adding both functionality and aesthetic value to buildings.

- Industrial Applications: Employed in factories for machine guards, ventilation systems, noise barriers, and industrial sieves. It is also used in the automotive industry for engine cooling, air intake grilles, and exhaust shields.

- Filtration and Separation: Ideal for applications in the food processing, pharmaceutical, chemical, and water treatment industries, where it is used for filtering, sieving, and separating materials based on size and particle characteristics.

- Furniture and Interior Design: Incorporated into furniture design, such as room dividers, cabinet doors, and table tops, providing a modern and stylish look while maintaining functionality.

7. Customization Services

We understand that each project has unique requirements. Therefore, we offer comprehensive customization services for our 304 stainless steel perforated mesh sheets. Customers can customize the board size, thickness, hole shape, hole size, hole pitch, surface treatment, and even special processing requirements. Our experienced engineering team will work closely with customers, using CAD/CAM technology to provide detailed design drawings and technical support throughout the customization process, ensuring that the final product meets all specifications and application needs.

8. Quality Assurance

Quality is our top priority. From raw material procurement to the final product delivery, every step of the production process is strictly monitored. All 304 stainless steel raw materials are sourced from reliable suppliers and undergo strict quality inspection upon arrival. During production, in - process quality control checks are carried out at various stages, including punching, edge processing, and surface treatment. The finished products are inspected according to international quality standards, such as ISO 9001:2015, to ensure dimensional accuracy, surface quality, and mechanical properties. We also provide material certificates and quality inspection reports for each batch of products, giving customers full confidence in the quality and reliability of our 304 stainless steel perforated mesh sheet

![]()

![]()

![]()

![]()

Recommended Products