All Products

-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

316Ti Stainless Steel Plate Stocked in Various Thickness & Sizes Laser Cutting

| Place of Origin | China |

|---|---|

| Brand Name | TISCO BAOSTEEL |

| Certification | ISO |

| Model Number | 316Ti / 1.4571 |

| Minimum Order Quantity | 500 kgs |

| Price | 3000 - 3500 USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | T/T, Western Union |

| Supply Ability | 20Ton per week |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

xProduct Details

| Products | Stainless Steel Plate | Grade | 316Ti / 1.4571 |

|---|---|---|---|

| Thickness | 0.6 - 80.0mm | Width | 1500mm 1219mm 1000mm |

| Surface | NO.1 | Brand | BAOSTEEL TISCO |

| Standard | ASTM A240/240M | Loading Port | Shanghai Port |

Product Description

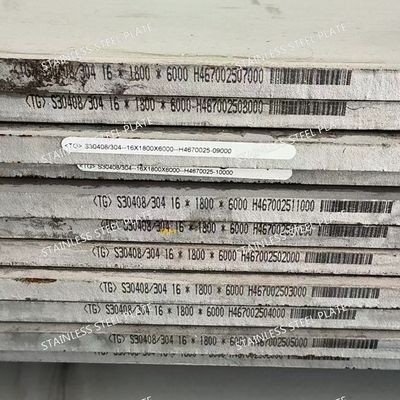

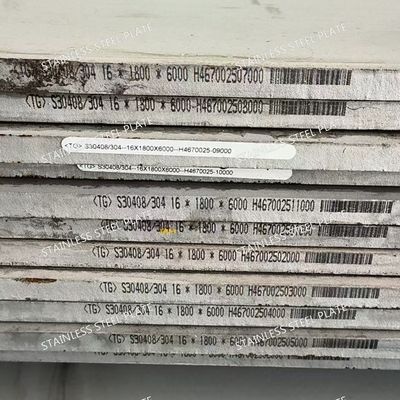

316Ti Stainless Steel Plate Stocked in Various Thickness & Sizes Laser Cutting

Products Specification

| Products Name | 316Ti Stainless Steel Plate |

| Main Grades | Stainless Steel J1, J2, J4, 201, 202, 301, 304, 304H, 304L, 309, 309S, 310, 310S, 316, 316L, 316TI, 321, 321H, 347, 409, 410, 410S, 420, 430, 441, 904L,630,631,254SMO,253MA,2205,2507.etc |

| Thickness | 3.0 - 80.0mm |

| Width | 1250mm,1500mm ,1800mm,2000mm, or custom other size as request |

| Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, AS PER CUSTOMER’S REQUIREMENT |

| Type of Material | Laser Cutting |

| Form | Plate / coil |

| Test Certificate | Yes. |

| Finish | NO.1, 2B, 2D, 2H, 2R, No.4, HAIRLINE, SCOTCH BRITE, SATIN FINISH, NO.8, BA. |

| Brand | TISCO, LISCO,BAOSTEEL , POSCO, JISCO |

316Ti Stainless Steel Sheet Product Information

In the dynamic world of industrial materials, the 316Ti stainless steel sheet emerges as a game - changer, offering a blend of resilience, versatility, and efficiency that addresses the most pressing challenges across diverse sectors.

A Cut Above: The Alloy Formula

At the heart of 316Ti's prowess lies its meticulously crafted alloy composition. Carbon is tightly regulated below 0.08%, a strategic move that thwarts carbide formation and subsequent intergranular corrosion. The chromium - nickel matrix, with chromium at 16.00 - 18.00% and nickel at 10.00 - 14.00%, acts as a formidable shield against oxidation. Molybdenum, present in the range of 2.00 - 3.00%, supercharges resistance to pitting and crevice corrosion, particularly in chloride - rich settings. But it's the addition of titanium that truly sets 316Ti apart. By sequestering carbon atoms, titanium ensures the material's integrity remains intact even when subjected to thermal cycling and stress - prone environments.

Engineering Marvel: Physical and Mechanical Traits

- Physical Attributes: With a density of 7.98 g/cm³, 316Ti strikes the perfect balance between heft and strength. Its broad melting range of 1375 - 1450 °C makes it adaptable to high - temperature applications, while a thermal conductivity of 16 W/m·K at 100 °C enables efficient heat management. The coefficient of thermal expansion, measured at 16.0×10⁻⁶/K (20 - 100 °C), guarantees dimensional stability through temperature swings.

- Mechanical Mastery: Boasting a tensile strength of ≥515 MPa and a yield strength (0.2% offset) of ≥205 MPa, 316Ti stands firm under heavy loads. Its 40% elongation at break and ≤200 HB hardness endow it with remarkable ductility, allowing for complex shaping without compromising structural integrity.

Features that Redefine Standards

Corrosion Resistance: A Shield Against the Elements

In the unforgiving marine environment, where salt spray and humidity conspire against materials, 316Ti stainless steel sheets have proven their mettle. Take, for instance, the construction of a major offshore wind farm. Our 316Ti sheets were used for the support structures, withstanding the corrosive sea air for over a decade without significant degradation. In chemical plants, handling aggressive acids and alkalis, 316Ti's superior resistance ensures that reactors and pipelines maintain peak performance, slashing maintenance costs and downtime.

High - Temperature Resilience: Performing Under Pressure

In power generation plants, 316Ti stainless steel sheets are the unsung heroes in boiler components and heat exchangers. They endure continuous exposure to temperatures up to 800 °C, resisting oxidation and creep deformation. This reliability translates to extended equipment lifespans and reduced replacement cycles, boosting overall plant efficiency.

Fabrication - Friendly: From Concept to Reality

Our 316Ti sheets are designed with fabricators in mind. Cold - forming processes like stamping and bending are seamless, enabling the creation of intricate designs for architectural projects. Welding is a breeze too; our sheets maintain their corrosion - resistant properties at the joints, ensuring the final product is as robust as intended.

Precision - Engineered Manufacturing

Our production process is a testament to technological innovation. Starting with electric arc furnace melting, we ensure precise alloy composition. The material then undergoes hot rolling for initial shaping, followed by cold rolling for a refined finish and tight tolerances. Advanced heat - treatment techniques optimize its mechanical properties. Rigorous quality control checks at every stage, including non - destructive testing and chemical analysis, guarantee that each sheet meets the highest standards.

Tailored to Your Needs: Specifications

- Thickness: Ranging from ultra - thin 0.1 mm for delicate applications to a sturdy 80 mm for heavy - duty structures.

- Width: Available from 400 mm to 3000 mm, catering to various project scales.

- Length: Custom lengths up to 20000 mm are offered to minimize waste.

- Surface Finishes: Choose from 2B (matte finish for general use), BA (bright finish for decorative applications), No. 4 (satin finish for architectural elements), and 8K (mirror finish for high - end designs).

Applications Across Industries

- Food and Beverage: In food processing facilities, 316Ti's hygienic surface prevents bacteria growth, making it ideal for equipment, tanks, and conveyor belts. It complies with strict food safety regulations, ensuring product integrity.

- Medical: For medical implants and surgical instruments, 316Ti's biocompatibility and corrosion resistance are non - negotiable. It provides a safe and reliable option for direct human contact applications.

- Sustainable Construction: In green building projects, 316Ti's long lifespan and recyclability contribute to environmental sustainability. Its resistance to weathering makes it perfect for outdoor facades and structural elements.

Quality Assurance and Sustainability

Our 316Ti stainless steel sheets adhere to international standards such as ASTM A240, EN 10088, and JIS G4305. We hold ISO 9001:2015 certification for quality management. Additionally, our commitment to sustainability is evident in our recycling initiatives. At the end of its service life, 316Ti can be recycled without loss of performance, reducing the environmental footprint.

![]()

![]()

![]()

![]()

Recommended Products