-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

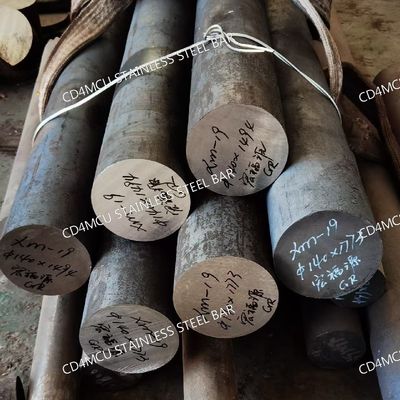

CD4MCU Super Stainless Steel Round Bar / Rod Diameter 10 - 350mm Hot Rolled Steel Bars

| Products Name | CD4MCU Stainless Steel Bar | Diameter | 10 - 350mm |

|---|---|---|---|

| Length | 6m Or Cutting Any Length As Request | Surface | Pickling Or Bright |

| Service | Cutting | Standard | ASTM DIN GB EN |

| Other Products | Round Bar, Square Bar, Flat Bar.etc | Technique | Hot Rolled |

| Highlight | CD4MCU Stainless Steel Round Bar,Hot Rolled Stainless Steel Round Bar,Super Stainless Steel Round Bar |

||

CD4MCU Super Stainless Steel Round Bar / Rod Diameter 10 - 350mm Hot Rolled Steel Bars

Products Specification

| Products Name | Stainless Steel Round Bar |

| Grade | CD4MCU |

| Products Diameter Range | φ10mm - φ350mm |

| Length | 6.1m/pcs or cutting any length as request |

| Surface | Pickling finishing, bright finishing |

| Other Grade |

304,304L,309S,310S,310H,316L,316Ti,316H,317L,321,329,347,410,420, 430F,431,440A/B/C,2205,2507,904l,254SMO,253MA,CD4MCU,XM-19,17-4PH,15-5PH,17-7PH,C276,600,601,625,718,800,800H,825,926.etc |

| Standard | ASTM JIS,GB,DIN EN |

| Service | Cutting |

| Other Shape | Square , Flat, Hexagonal, Round.etc |

| Loading Port | Shanghai Port |

| MOQ | 500 kgs |

Introduction

CD4MCU is a duplex (ferritic-austenitic) stainless steel known for its high strength, excellent corrosion resistance (especially in chloride environments), and good wear resistance. It contains a balanced microstructure of austenite and ferrite, along with additions of copper (Cu) and molybdenum (Mo) for enhanced performance in aggressive environments.

Key Parameters

-

Chemical Composition (Typical %)

-

C: ≤0.04

-

Cr: 24.5–26.5

-

Ni: 4.75–6.00

-

Mo: 1.75–2.25

-

Cu: 2.75–3.25

-

N: 0.10–0.25

-

Fe: Balance

-

-

Mechanical Properties

-

Tensile Strength: 750–1000 MPa

-

Yield Strength: ≥550 MPa

-

Elongation: ≥15%

-

Hardness: ≤290 HB

-

-

Physical Properties

-

Density: ~7.8 g/cm³

-

Melting Point: ~1420–1460°C

-

Standards

-

ASTM A995/A995M (Castings for pressure-containing parts)

-

ASTM A890 (Similar duplex stainless steel castings)

-

UNS J93370 (Unified Numbering System designation)

Key Features

-

Superior Corrosion Resistance: Resists pitting, crevice corrosion, and stress corrosion cracking (SCC) in chloride-rich environments (e.g., seawater, chemical processing).

-

High Strength: Nearly double the yield strength of standard austenitic steels (e.g., 316L).

-

Wear & Erosion Resistance: Ideal for abrasive/erosive conditions.

-

Good Weldability: Requires proper techniques (e.g., low heat input, post-weld annealing).

Similar Grades

-

F51 (1.4462) / 2205: Lower Cu content, widely used duplex steel.

-

F55 (1.4501) / 2507: Super duplex with higher Cr, Mo, and Ni.

-

CD3MN (F53): Another duplex grade but without Cu.

Applications

-

Oil & Gas: Subsea components, valves, pumps.

-

Chemical Processing: Reactors, heat exchangers, piping.

-

Marine Engineering: Propeller shafts, seawater systems.

-

Power Plants: Flue gas desulfurization (FGD) systems.

-

Pulp & Paper Industry: Bleaching equipment.

This summary provides a concise yet comprehensive technical profile of CD4MCU round bars. Let me know if you need further details!

![]()

![]()

![]()

![]()