-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

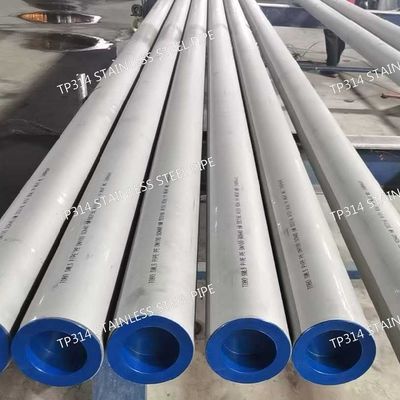

6m Length 314 Stainless Steel Seamless Pipe DN100 DN200 DN300 SCH80S SCH160S For Boiler

| Products | Stainless Steel Seamless Pipe | Grade | 314 |

|---|---|---|---|

| Diameter | DN100 - DN400 | Length | 6m Or Custom Cutting Any Length As Request |

| Standard | ASTM EN | Service | Cutting |

| Loading Port | Shanghai Port | Thickness | 4.0 - 50.0mm |

| Highlight | DN200 Stainless Steel Seamless Pipe,DN300 Stainless Steel Seamless Pipe,DN100 Stainless Steel Seamless Pipe |

||

6m Length 314 Stainless Steel Seamless Pipe DN100 DN200 DN300 SCH80S SCH160S for Boiler

Products Specification

| Products Name | Stainless Steel Seamless Pipe |

Grade: |

304 304L 309S 310S 314 316L 316Ti 321 329 347H 410 2205 2507 904L 254SMO and equal grade in GB JIS EN DIN Standard |

| Standards: | ASTM A213M-94b ASTM A249M-94a ASTM A269-94a ASTM A312M-94b,ect. |

| DIN 17456-85 DIN 17458-85 DIN 17459-92.ect | |

| JIS G3446-1994 JIS G3448-1997 JIS G3459-1997 JIS G3463-1994,ect. | |

| GB13296-1991 GB14975-2002 GB14976-2002,ect. | |

| Size: | ND5 - DN400 |

| Length: | 6m length or cutting any length as request |

| Applications: | fluid and gas transport, structure , boiler, heat exchanger, super heater |

314 stainless steel is an austenitic stainless steel containing high alloys. It is part of the 300 stainless steel series.

Unlike other stainless steels, it is popular for its resistance to oxidation and scaling at extreme temperatures because of its high chromium and nickel content. This composition facilitates its performance and makes it ideal for your applications in intense and corrosive environments.

Other Names or Designations for Stainless Steel 314

- The unified numbering system: UNS S31400

- The designation in Germany or Europe: DIN 1.4841

- Designation as per the American Iron and Steel Institute: AISI 314

- Designation as per the Japanese Industrial Standard: JIS SUS314

- The European equivalent in the EN standard: X15CrNiSi25-20

Chemical Composition of Stainless Steel Grade 314

| Element | Amount in % and Function in the Austenitic Stainless Steel Grade |

| Chromium (Cr) | Its amount ranges between 23% and 26. It forms (Cr203) a passive oxide layer with self-healing properties that protect the surface. It is important for corrosion and oxidation resistance. |

| Silicon (SI) | Its amount ranges between 1.5% and 3%. During extreme temperatures, SI enhances oxidation resistance which promotes thermal stability that enables your material to be able to withstand thermal cycling. |

| Nickel (NI) | It amounts to between 19% and 22% of Stainless Steel grade. Usually, this helps to stabilize this stainless steel grade in terms of its resistance to acidic conditions and other environments at extreme temperatures. |

| Iron (Fe) | It is the primary element in stainless steel. It is responsible for Stainless Steel’s structure and toughness. It creates the matrix for alloying elements. |

| Sulfur (S) | It amounts to less than or equal to 0.030%. It enhances machinability but you must keep it at low amounts to preserve Stainless steel’s toughness and resistance to corrosion. |

| Carbon (C) | It amounts to less than or equal to 0.25%. You must regulate Its proportion to prevent carbide precipitation at grain boundaries which lowers corrosion resistance. It enhances strength through solid solution strengthening. |

| Manganese (Mn) | It amounts to less than or equal to 0.2%. During production, it helps with deoxidization improving hot-working properties and enhancing stability at the austenitic phase. |

| Phosphorus (P) | It amounts to less than or equal to 0.045%. It is an impurity that is regulated to enhance machinability. If present in large amounts, it can tamper with the toughness and corrosion resistance of your stainless steel. |

314 Stainless Steel Properties

· Yield Strength

Yield strength is the level of stress where your material starts to deform permanently. 314 Stainless Steel has a yield strength of 205 MPa. This signifies that your 314 SS can put up with moderate loads before it deforms permanently.

It has a lower yield strength compared to some duplex stainless steels allowing it to bear with thermal expansion without breaking. This makes it efficient for your extreme temperature applications.

· Tensile Strength

Tensile strength is the highest amount of stress your material can bear while being stretched before it finally breaks. 314 SS has a high tensile strength of 655 MPa.

High tensile strength enables 314 SS to handle heavy loads and withstand mechanical stress in your applications such as furnace components. Together with perfect toughness, it ensures durability in intense thermal environments.

· Magnetic Properties

314 Stainless Steel is austenitic, which signifies that in its annealed state, it is non-magnetic.

314 SS, because of its high nickel amount, has a face-centered cubic crystal.314 SS’s non-magnetic property makes it ideal for your applications such as electronics where magnetism is not desired.

· Corrosion Resistance

314 SS has excellent resistance to corrosion particularly in oxidizing conditions. It has high chromium and silicon content that creates a protective layer that prevents oxidation and scaling at very high temperatures.

Additionally, 314 SS has high amounts of nickel that offers strong resistance to acid attacks and corrosive chemicals. It also has silicon that facilitates its resistance to scaling.

· Welding

314 Stainless Steel has an austenitic structure, high nickel and chromium amounts making it highly weldable.314 SS aids all common methods of welding like shielded metal arc welding, resistance welding, and Tungsten Inert Gas.

You are not required to Preheat and perform post-weld annealing except in extremely corrosive environments.

Here is more information on stainless steel welding.

· Heat Treatment

Your 314 Stainless steel cannot be hardened by heat treatment because of its austenitic structure but it can undergo heat processes for purposes such as solution annealing and stress relief.

Solution annealing is necessary to optimize ductility and restore the ability to withstand corrosion while stress relief is essential to minimize strength resulting from machining.

You can utilize Heat treatment properties in high-temperature environments to maintain durability and stability.

· Machinability

314 Stainless Steel is machinable but at a moderate level. It is a little bit harder to machine as ferritic grades. The high amounts of nickel and chromium content toughness and hardness of the material make machining difficult.

314 SS’s machinability falls from 40% to 50% on a free-machining steel scale rated at 100%. You can also learn more about machining stainless steel.

· Oxidation Resistance

314 SS has perfect oxidation resistance because of its high chromium and silicon content that creates a protective oxide layer on the surface that prevents oxidationand Scaling.

This makes it suitable for your applications that involve extreme temperatures.

· Cold Forming

314 SS portrays good cold-forming properties. It contains high nickel and chromium content giving it the required ductility and enabling it to be cold-formed into several complex shapes without cracking.

During forming, 314 SS displays a higher springback impact than ferritic grades. This necessitates the need for allowances for elastic recovery in design and tooling.

Main 314 SS Uses

- You can use 314 SS as a liner in your industrial furnace as it resists heat without losing its integrity.

- You can use it in steel manufacturing and glass production because of its ability to resist scaling.

- You can use 314 SS in thermal processing machines such as thermal reactors because of its ability to maintain high strength at increased temperatures. This enables thermal cycling without failure.

- 314 Stainless Steel can be used in petrochemical and chemical industries for reactors and vessels since they are resistant to oxidizing conditions ensuring durability.

- 314 SS is used in exhaust manifolds, and turbocharger housings in the automotive and aerospace industries because it combines heat resistance and mechanical strength ensuring durability.

- It is used in food processing equipment as it is corrosion resistant maintaining and making it clean over time.

- You can use 314 SS can in heat exchangers and turbine components in power plant industries. Its performance is efficient with minimal downtime.

FAQ

1. Is 314 better than 316 Stainless Steel?

314 and 316 SS are tailored for different purposes hence the better choice depends on the application. 314 SS is most suitable for high-temperature applications such as industrial heating apparatus.

On the other hand, 316 SS is most suitable for applications that need superior resistance to corrosion such as chemical industries.

2. What is the difference between 304 and 314 SS?

314SS is suitable for extreme heat applications while 304 SS is not suitable for prolonged use over high temperatures.

314 SS contains a higher level of chromium and nickel compared to 304 SS. This makes 314SS more expensive than 304 SS.

304 SS offers better corrosion resistance and has a well-balanced composition while 314 SS lacks molybdenum making it weaker in environments with chloride exposure.

3. What is the 314 Stainless Steel Equivalent?

UNS: S31400, EN: 1.4841, DIN: X15CrNiSi25-21, and JIS: SUH 310 are some of the equivalents of 314 SS.

4. Is 314 Stainless Steel Food Grade?

Yes, 314 Stainless Steel is food grade. It can be used in high-temperature food processing.

5. What is the average 314 Stainless Steel Price per Ton?

The average price of 314 Stainless steel lies between $4500 and $6500 per ton.

![]()

![]()

![]()

![]()