-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

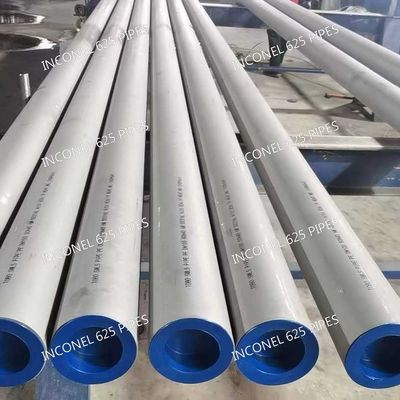

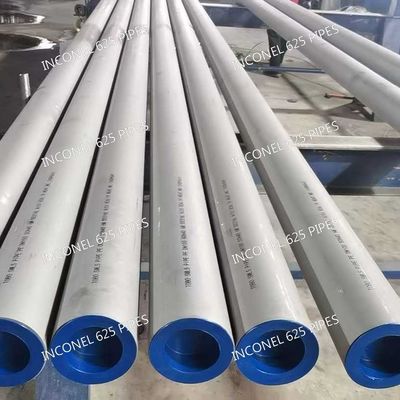

Inconel 625 Nickel Alloy Seamless Pipe UNS N06625 6m Length SCH40S Hollow Tube

| Products | Nickel Alloy Pipe | Grade | Inconel 625 |

|---|---|---|---|

| Diameter | DN10 - DN300 | Length | 6m Or Custom Cutting Any Length As Request |

| Standard | ASTM EN | Service | Cutting |

| Loading Port | Shanghai Port | Thickness | 0.5 - 40.0mm |

| Highlight | 6m Nickel Alloy Seamless Pipe Tube,SCH40S Nickel Alloy Seamless Pipe Tube,Hollow inconel 625 pipe |

||

Inconel 625 Nickel Alloy Seamless Pipe Tube UNS N06625 6m Length SCH40S Hollow Tube

Products Specification

|

Model

|

Nickel Tubes Pipes

|

|||

|

Material Grade

|

Inconel 600, Inconel 601, Inconel 625, Inconel 690, Inconel 718, Inconel 725, etc

Incoloy 800, Incoloy 825, Incoloy 925, Incoloy 800H, Incoloy 800, Incoloy926(AL-6XN), etc

Hastelloy C276, Hastelloy C22, Hastelloy C2000, Hastelloy X, etc |

|||

|

Diameter

|

a) Capillary Tube Outer Diameter: 0.2mm-6.mm

Welding Tube Outer Diameter: 6.mm- 840mm

Seamless Tube Outer Diameter: 6mm-630mm

|

|||

|

b) Capillary Tube Wall Thickness: 0.02mm-2mm

Welding Tube Wall Thickness: 0.5-150mm

Seamless Tube Wall Thickness: 0.5-60mm

|

||||

|

c) Length: ≤500mm Or in coil

|

||||

|

Tolerance

|

a) Outer Diameter: +/- 0.01mm

|

|||

|

b) Thickness: +/- 0.01mm

|

||||

|

c) Length: +/- 0.1mm

|

||||

|

Surface Treatment

|

Polishing,Annealing, Bright, Pickling

|

|||

|

Type

|

Welded,Seamless

|

|||

|

Shape

|

Round,Square,Irregular

|

|||

|

Application

|

medical treatment, petroleum, aerospace, medical equipment, air conditioning, chemical industry, electronics, accessories, food machinery, power generation, pharmaceutical and other fields.

|

|||

Inconel 625 Tubing Description

Inconel 625 is a nickel-chromium-molybdenum superalloy renowned for its exceptional corrosion resistance, high strength, and outstanding performance in extreme environments. The tubing form is widely used in aerospace, chemical processing, and marine industries due to its ability to withstand oxidation, pitting, and crevice corrosion.

Key Parameters of Inconel 625 Pipe Tube

-

Composition:

-

Nickel (Ni): ≥58%

-

Chromium (Cr): 20–23%

-

Molybdenum (Mo): 8–10%

-

Niobium (Nb): 3.15–4.15%

-

Iron (Fe): ≤5%

-

Others: Al, Ti, C, Mn, Si (trace amounts)

-

-

Mechanical Properties:

-

Tensile Strength: ≥830 MPa (120 ksi)

-

Yield Strength: ≥415 MPa (60 ksi)

-

Elongation: ≥30%

-

Hardness: ≤90 HRB

-

-

Temperature Range:

-

Cryogenic to 982°C (1800°F) (continuous service).

-

Specifications & Standards

-

ASTM Standards:

-

ASTM B444 / B444M (seamless pipe)

-

ASTM B704 / B705 (welded tubing)

-

ASTM B829 (general requirements)

-

-

Other Standards:

-

ASME SB-444, SB-704, SB-705

-

EN 10269, DIN 17752

-

NACE MR0175 (sulfide stress cracking resistance)

-

Features of Inconel 625 / Alloy 625

-

Corrosion Resistance: Excellent resistance to seawater, acidic, and chloride-rich environments.

-

High Strength: Maintains mechanical properties at elevated temperatures.

-

Oxidation Resistance: Stable in oxidizing atmospheres up to 980°C.

-

Fabrication Flexibility: Can be welded, machined, and formed with proper techniques.

Advantages of Inconel 625 / UNS N06625 Alloy

-

Long service life in harsh conditions.

-

Superior fatigue and thermal fatigue resistance.

-

Minimal need for protective coatings.

Comparable Grades

-

UNS N06625 (equivalent to Inconel 625)

-

Alloy 625 (common alternate name)

-

2.4856 (EN/DIN designation)

-

NS336 (Chinese GB standard)

Packing Method of our Pipes

-

Standard: Plastic caps on ends, wooden crates, or waterproof wrapping.

-

Customization: VCI (Vapor Corrosion Inhibitor) paper or nitrogen purging for sensitive applications.

Applications of Inconel 625 Pipes

-

Aerospace: Engine exhaust systems, fuel lines.

-

Oil & Gas: Downhole tubing, umbilicals, risers.

-

Chemical Processing: Heat exchangers, reactor vessels.

-

Marine: Seawater pipelines, offshore platforms.

-

Nuclear: Radioactive waste handling systems.

![]()

![]()

![]()

![]()