-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

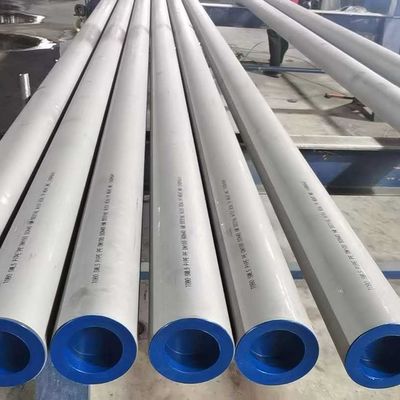

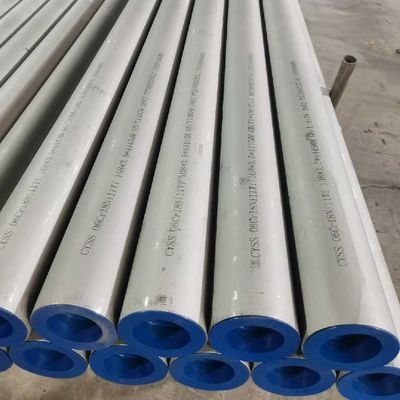

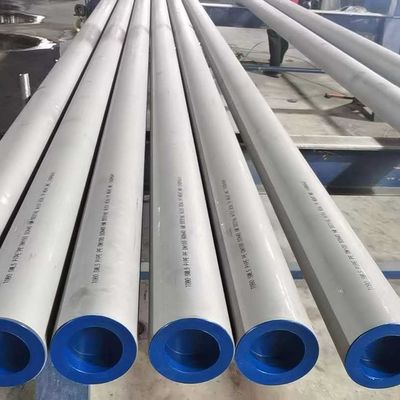

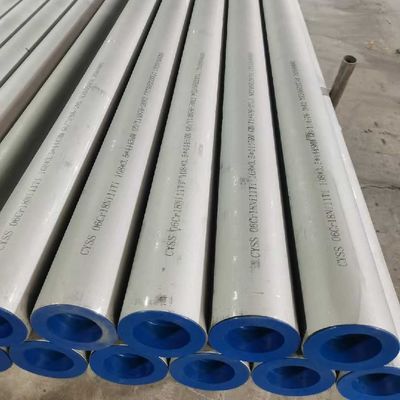

ASTM A312 TP347HFG Seamless Stainless Steel Pipe Tube

| Place of Origin | China |

|---|---|

| Brand Name | DELTA |

| Certification | ISO |

| Model Number | 201 304 316L 321 310S 314 347 2205 2507 904L.etc |

| Minimum Order Quantity | 500 kgs |

| Price | 2400 - 3500 USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | T/T, Western Union, L/C |

| Supply Ability | 10 Ton per week |

| Products | TP347HFG Stainless Steel Pipe | Grade | TP347HFG |

|---|---|---|---|

| Standard | ASTM GB EN | Length | 6m Or As Request |

| Diameter | 6 - 219mm Or As Clients Request | Wall Thickness | 0.4 - 8.0mm |

| Type | Seamless Pipe | Service | Cutting |

| Other Shape | Square, Rectangle | ||

| Highlight | ASTM A312 Stainless Steel Pipe,TP347HFG Stainless Steel Pipe,ASTM A312 Seamless Stainless Steel Tube |

||

ASTM A312 TP347HFG Seamless Stainless Steel Pipe Tube

Products Specification

| Standard | ASTM A312 |

| Pipe Type | Bright Annealed Stainless Steel Tubing |

| Grades | 304, 304L, 316, 316L, 321, 310S, 2205, 2507,347,TP347HFG |

| Dimensions | Outer Diameter (OD): 10 mm to 610mm |

| Wall Thickness | 1mm to 50.0 mm |

| Length | Up to 12 meters (custom lengths available upon request) |

| Manufacturing Process | Cold Drawn, Bright Annealed, Seamless |

| Material Surface Finish | Bright Annealed (BA), Mirror Polished, Pickling |

| End Type | Plain End (PE), Beveled End (BE), Threaded End (TE) |

| Certifications | ISO 9001, EN 10204 3.1 |

TP347HFG Stainless Steel Pipe

1. Overview

TP347HFG is a high-temperature austenitic stainless steel designed for elevated-temperature service, particularly in power plants and petrochemical industries. It is a modified version of TP347H with fine grain (FG) structure, offering improved creep resistance and long-term durability under stress at high temperatures.

2. Chemical Composition (ASTM A213/A312)

| Element | Composition (%) |

|---|---|

| Carbon (C) | 0.06–0.10 |

| Manganese (Mn) | ≤2.00 |

| Silicon (Si) | ≤0.75 |

| Phosphorus (P) | ≤0.040 |

| Sulfur (S) | ≤0.030 |

| Chromium (Cr) | 17.0–20.0 |

| Nickel (Ni) | 9.0–13.0 |

| Niobium (Nb) | 8×C min – 1.00 |

| Iron (Fe) | Balance |

Key Notes:

-

Niobium (Nb) stabilizes the alloy against sensitization and intergranular corrosion.

-

Controlled carbon content enhances high-temperature strength.

3. Mechanical Properties

| Property | Value (Typical) |

|---|---|

| Tensile Strength (Room T) | ≥515 MPa (75 ksi) |

| Yield Strength (Room T) | ≥205 MPa (30 ksi) |

| Elongation (% in 50mm) | ≥35% |

| Hardness (Brinell) | ≤201 HB |

| Creep Strength (600°C) | Excellent |

High-Temperature Performance:

-

Retains strength and oxidation resistance up to 800°C (1472°F).

-

Superior creep rupture strength compared to standard TP347H.

4. Characteristics & Advantages

Key Features:

-

Fine Grain Structure (FG): Enhances creep resistance and reduces crack propagation.

-

Oxidation & Corrosion Resistance: Performs well in sulfur-rich and steam environments.

-

Weldability: Suitable for welding with proper techniques (e.g., low heat input).

-

Thermal Stability: Resists scaling and carburization in high-temperature service.

Advantages over TP347H:

-

Longer service life in superheaters/reheaters (power boilers).

-

Reduced risk of stress corrosion cracking (SCC).

-

Better microstructural stability under cyclic heating.

5. Applications

TP347HFG is widely used in:

-

Power Generation:

-

Superheater/reheater tubes in coal-fired and biomass boilers.

-

High-pressure steam pipelines (up to 620°C).

-

-

Petrochemical Industry:

-

Crackers, reformers, and furnace tubes.

-

-

Oil & Gas:

-

Exhaust systems and heat exchangers.

-

-

Nuclear Plants:

-

Secondary steam circuits.

-

6. Standards & Certifications

-

ASTM A213/A312: Seamless/welded pipes.

-

ASME SA213/SA312: Pressure vessel compliance.

-

EN 10216-5: European standard for high-temperature tubes.

Conclusion

TP347HFG stainless steel pipes are engineered for extreme heat and pressure, combining fine-grain metallurgy with superior creep resistance. Their reliability in power plants and corrosive environments makes them a premium choice for critical high-temperature applications.

Let me know if you need additional details!

![]()

![]()

![]()

![]()