-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

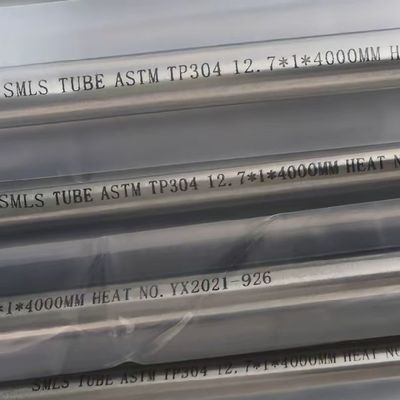

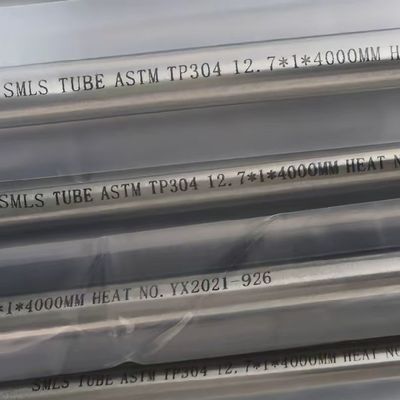

TP316L Stainless Steel Pipe 6.35*0.89 / 8*1mm,10*1mm,12.7*1.24mm / 25.1*1.65mm

| Place of Origin | China |

|---|---|

| Brand Name | DELTA |

| Certification | ISO |

| Model Number | 201 304 316L 321 310S 314 347 2205 2507 904L.etc |

| Minimum Order Quantity | 500 kgs |

| Price | 2400 - 3500 USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | T/T, Western Union, L/C |

| Supply Ability | 10 Ton per week |

| Products | BA Stainless Steel Pipe | Grade | 304 316L 321 2205 310S 904L.etc |

|---|---|---|---|

| Standard | ASTM GB EN | Length | 6m Or As Request |

| Diameter | 6 - 219mm Or As Clients Request | Wall Thickness | 0.4 - 8.0mm |

| Type | Seamless Pipe | Service | Cutting |

| Other Shape | Square, Rectangle | ||

| Highlight | 25.1*1.65mm Stainless Steel Pipe |

||

Bright Annealed AP BA EP Stainless Steel Pipe TP316L SS Pipe Precision Tube

Products Specification

| Standard | ASTM A213, ASTM A269, ASME SA213, ASME SA269 |

| Pipe Type | Bright Annealed Stainless Steel Tubing |

| Grades | 304, 304L, 316, 316L, 321, 310S, 2205, 2507 |

| Dimensions | Outer Diameter (OD): 1.00 mm to 76.2 mm |

| Wall Thickness | 0.2 mm to 6.0 mm |

| Length | Up to 12 meters (custom lengths available upon request) |

| Manufacturing Process | Cold Drawn, Bright Annealed, Seamless |

| Material Surface Finish | Bright Annealed (BA), Mirror Polished, No. 4 Finish |

| End Type | Plain End (PE), Beveled End (BE), Threaded End (TE) |

| Certifications | ISO 9001, EN 10204 3.1 / 3.2, PED, ASME |

Introduction of BA Stainless Steel Tube

BA Stainless Steel Tube, known for its excellent surface finish, cleanliness, and high dimensional accuracy, is essential for industries requiring ultra-clean, high-purity conditions. These include sectors like biopharmaceuticals, semiconductors, liquid crystal displays (LCD), solar photovoltaic systems, and other high-tech fields. BA tubing undergoes a vacuum or controlled atmosphere heat treatment, producing a bright, reflective surface without oxidation, making it ideal for applications that require purity and corrosion resistance.

Materials and Standards of BA Stainless Steel Tube

Manufacturers typically use 304 and 316L stainless steels to produce BA stainless steel tubes, ensuring excellent corrosion resistance, strength, and versatility. These tubes adhere to various international standards, such as:

- ASTM A249, ASTM A269, ASTM A270, 3A, and BPE standards for the US.

- JIS G3447 and G3459 for Japan.

Manufacturing Process of BA Stainless Steel Tube

BA Stainless Steel Tube is primarily cold-rolled, offering high dimensional precision (up to 0.2%) and superior surface quality (Ra < 0.45 µm). Unlike polished tubes, the inner surface of BA tubing retains its smoothness, thanks to the advanced annealing process. Raw materials must comply with ASTM A269; in some cases, double-melted steel is employed for enhanced purity.

Characteristics of BA Stainless Steel Tube

BA Stainless Steel Tube is highly prized for its exceptional dimensional accuracy, smooth surface, and cleanliness. Moreover, their inner surface is softer than polished alternatives, making them ideal for ultra-clean applications. Additionally, the process ensures high precision, with dimensional accuracy reaching up to ±0.05 mm and surface roughness (Ra) approaching 0.4 µm.

Heat Treatment (Bright Annealing)

The heat treatment process, or bright annealing, occurs in a reducing atmosphere, where oxygen is minimized to prevent oxidation. This controlled environment maintains the tube’s smooth, reflective surface and optimizes its mechanical properties. As a result, the tubes are free of scale and, therefore, do not require further pickling or passivation.

Cleaning and Inspection of BA Stainless Steel Tube

Before leaving the production facility, BA tubes undergo an extensive cleaning process. Ultrasonic cleaning with degreasing agents like SC2286 removes oils and contaminants, ensuring ultra-clean surfaces are suitable for high-purity environments. Inspections involve methods like eddy current testing and hydraulic pressure tests to guarantee the absence of defects.

Finishing and Packaging of BA Stainless Steel Tube

After production, BA stainless steel tubes are straightened, cut to precise lengths, and polished to remove minor imperfections. Packaging typically includes several protective layers, such as PE bags, end caps, and anti-static materials, ensuring the tubes remain contamination-free during transport and storage.

Applications of BA Stainless Steel Tube

BA stainless steel tubes find extensive use in industries requiring ultra-high purity gas or fluid transport. Specific industries and applications include:

- Biopharmaceuticals

- Semiconductors

- Clean rooms and laboratories

- LCD and solar photovoltaic manufacturing

- High-purity gas systems

- WFI (Water for Injection) systems

- Compressed air and ultra-pure chemical systems

![]()

![]()

![]()

![]()