All Products

-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

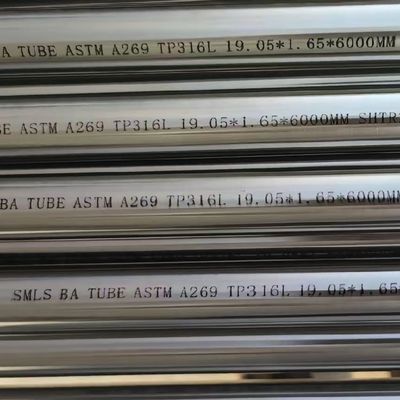

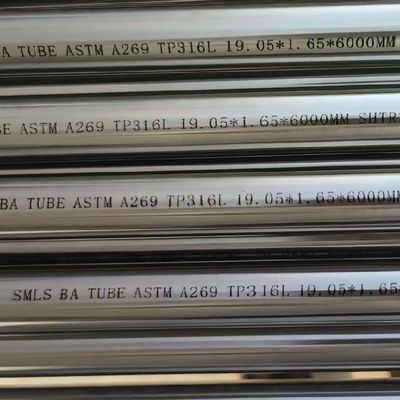

TP316L/1.4404 Stainless Steel Seamless Pipe Bright Annealed SS Pipe For Instrumentation Equipment

| Place of Origin | China |

|---|---|

| Brand Name | DELTA |

| Certification | ISO |

| Model Number | 201 304 316L 321 310S 314 347 2205 2507 904L.etc |

| Minimum Order Quantity | 500 kgs |

| Price | 2400 - 3500 USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | T/T, Western Union, L/C |

| Supply Ability | 10 Ton per week |

Product Details

| Products | BA Stainless Steel Pipe | Grade | 304 316L 321 2205 310S 904L.etc |

|---|---|---|---|

| Standard | ASTM GB EN | Length | 6m Or As Request |

| Diameter | 6 - 219mm Or As Clients Request | Wall Thickness | 0.4 - 8.0mm |

| Type | Seamless Pipe | Service | Cutting |

| Other Shape | Square, Rectangle | ||

| Highlight | 1.4404 Stainless Steel Seamless Pipe |

||

Product Description

TP316L/1.4404 Stainless Steel Seamless Pipe Bright Annealed SS Pipe For Instrumentation Equipment

Products Specification

| Standard | ASTM A213, ASTM A269, ASME SA213, ASME SA269 |

| Pipe Type | Bright Annealed Stainless Steel Tubing |

| Grades | 304, 304L, 316, 316L, 321, 310S, 2205, 2507 |

| Dimensions | Outer Diameter (OD): 1.00 mm to 76.2 mm |

| Wall Thickness | 0.2 mm to 6.0 mm |

| Length | Up to 12 meters (custom lengths available upon request) |

| Manufacturing Process | Cold Drawn, Bright Annealed, Seamless |

| Material Surface Finish | Bright Annealed (BA), Mirror Polished, No. 4 Finish |

| End Type | Plain End (PE), Beveled End (BE), Threaded End (TE) |

| Certifications | ISO 9001, EN 10204 3.1 / 3.2, PED, ASME |

. BA (Bright Annealed) Stainless Steel Tubes

Standards and Grades:

- Common Standards: ASTM A213, ASTM A269, ASTM A249, ASME BPE

- Grades: 304/304L, 316/316L, 317/317L

Manufacturing and Finishing Methods:

- Manufacturing: BA tubes can be produced through either seamless or welded processes, followed by bright annealing.

- Bright Annealing: Carried out in a controlled atmosphere (hydrogen or nitrogen) to prevent oxidation during heat treatment. To avoid any moisture that could cause oxidation, producers maintain the atmosphere at low dew points.

Characteristics:

- Surface Finish: The result is a reflective, bright, and smooth finish, free from oxides and scales.

- Corrosion Resistance: Enhanced due to the smooth, oxide-free surface.

- Surface Roughness: Ra typically below 0.8 μm.

Inspection Items:

- Tolerance of Outer Diameter & Wall Thickness: Dimensional accuracy checked according to specifications.

- Surface Roughness: A profilometer is used to measure the surface smoothness, ensuring it meets the requirements of clean industries.

- Visual and Cleanliness Inspection: Checked to ensure the bright surface is uniform and free of impurities.

- NDT: Ultrasonic or eddy current testing for weld integrity and defect detection.

Packaging Method:

- Producers individually wrap or cover BA tubes in plastic to maintain their cleanliness, preserve the bright surface, and prevent contamination or surface damage during handling.

Applications:

- Pharmaceutical and Biopharmaceutical: Due to the smooth, clean surface, BA tubes are used in sterile environments and piping systems.

- Food and Beverage: Hygienic applications where surface cleanliness is critical, especially in sanitary piping.

- High-Purity Gas Systems: BA tubes are used in systems where contaminants could affect the gas purity.

![]()

![]()

![]()

![]()

Recommended Products