-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

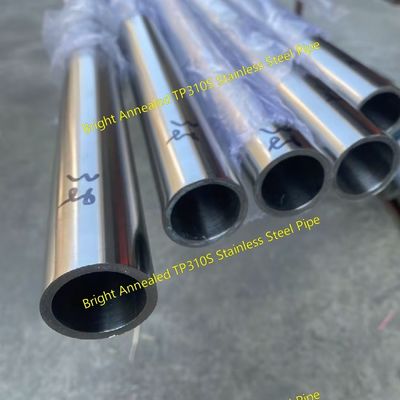

Cold Drawn 310S Stainless Steel Pipe ASTM SA269 SA213 SS Pipe Tube Bright Surface With Small Tolerance

| Place of Origin | China |

|---|---|

| Brand Name | DELTA |

| Certification | ISO |

| Model Number | 201 304 316L 321 310S 314 347 2205 2507 904L.etc |

| Minimum Order Quantity | 500 kgs |

| Price | 2400 - 3500 USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | T/T, Western Union, L/C |

| Supply Ability | 10 Ton per week |

| Products | TP310S Stainless Steel Pipe | Grade | 304 316L 321 2205 310S 904L.etc |

|---|---|---|---|

| Standard | ASTM GB EN | Length | 6m Or As Request |

| Diameter | 6 - 219mm Or As Clients Request | Wall Thickness | 0.4 - 8.0mm |

| Type | Seamless Pipe | Service | Cutting |

| Other Shape | Square, Rectangle | ||

| Highlight | Bright Surface Stainless Steel Pipe,Small Tolerance Stainless Steel Pipe,Cold Drawn Stainless Steel Pipe |

||

Cold Drawn 310S Stainless Steel Pipe ASTM SA269 SA213 SS Pipe Tube Bright Surface With Small Tolerance

Products Specification

| Standard | ASTM A213, ASTM A269, ASME SA213, ASME SA269 |

| Pipe Type | Bright Annealed Stainless Steel Tubing |

| Grades | 304, 304L, 316, 316L, 321, 310S, 2205, 2507 |

| Dimensions | Outer Diameter (OD): 1.00 mm to 76.2 mm |

| Wall Thickness | 0.2 mm to 6.0 mm |

| Length | Up to 12 meters (custom lengths available upon request) |

| Manufacturing Process | Cold Drawn, Bright Annealed, Seamless |

| Material Surface Finish | Bright Annealed (BA), Mirror Polished, No. 4 Finish |

| End Type | Plain End (PE), Beveled End (BE), Threaded End (TE) |

| Certifications | ISO 9001, EN 10204 3.1 / 3.2, PED, ASME |

1. Product introduction

310S stainless steel tube (UNS S31008) is a kind of high chromium nickel austenitic stainless steel, the Chinese brand is 0Cr25Ni20. Its high chromium (25%) and nickel (20%) content gives it excellent resistance to high temperature oxidation, corrosion resistance and good mechanical properties, suitable for high temperature and corrosive environments. Common forms include seamless and welded tubes that can be bright-annealed (BA) or pickled.

2. Chemical composition (%)

Element C≤ Si≤ Mn≤ P≤ S≤ Cr Ni

Standard value 0.08 1.0 2.0 0.045 0.03 24-26 19-22

3. Mechanical properties

Tensile strength (MPa) Yield strength (MPa) Elongation (%) Hardness (HB)

≥515 ≥205 ≥35 ≤187

4. Common specifications

- Outer diameter range: 6mm ~ 530mm (support customization)

- Wall thickness range: 0.5mm ~ 30mm

- Length: Regular 5.8m/6m, or as required.

- Surface treatment:

- Bright annealing (BA) : no oxide, Ra≤0.4μm.

- Pickling (AP) : Removal of oxide layer, matte surface.

5. Enforce standards

- Standard Type International Standard China standard European standard

- General purpose pipe ASTM A312 GB/T 14976 EN 10216-5

- Boiler/Heat Exchanger ASTM A213 GB/T 13296 -

- Welded Pipe ASTM A358 --

6. Characteristics and advantages

- High temperature resistance: the continuous use temperature can reach 1150℃ (intermittent use to 1200℃), the oxidation resistance is better than 304/316.

- Corrosion resistance: High chromium nickel resists vulcanization, chloride and weak acid and alkali corrosion.

- Processing performance: Austenitic structure is easy to cold work (such as bending, flaring).

- Smooth surface: BA treatment without polishing, suitable for clean environment (food, medicine).

- Long life: It is not easy to deform or precipitate carbide at high temperature, and the maintenance cost is low.

7. Comparison of similar brands

International Standards United States (UNS) Europe (EN) Japan (JIS) China (GB)

310S S31008 1.4845 SUS310S 0Cr25Ni20

8. Packing method

- Scratch-proof package: single PVC wrap + plastic sheath at both ends, wooden box/iron frame reinforcement.

- Moisture-proof packing: rust-proof paper + plastic film wrap (export standard).

- Special requirements: vacuum packing (high purity application) or pallet package.

9. Typical application areas

- High temperature equipment: boiler tube, heat exchanger, cracking furnace, burner nozzle.

- Chemical/petrochemical: acid medium pipeline, reactor, catalytic device.

- Environmental energy: flue gas desulfurization (FGD), waste incinerator, nuclear power components.

- Food and medicine: fermenter, sterile pipeline (BA surface required).

- Decoration project: high-grade building curtain wall, high temperature resistant decorative components.

10. Selection precautions

Reducing environment: In strongly reducing acids such as hydrochloric acid, corrosion resistance needs to be evaluated and higher grade materials (such as Hastelloy) may need to be selected.

Welding process: TIG welding is recommended to avoid intergranular corrosion caused by carbide precipitation.

![]()

![]()

![]()

![]()