-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

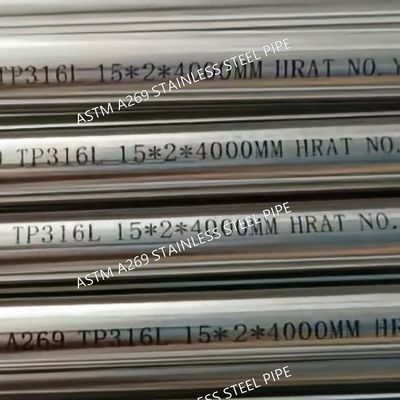

TP304 TP316L Stainless Steel Pipe Seamless Pipe Precison Cold Drawn SS Pipes ASTM A269

| Place of Origin | China |

|---|---|

| Brand Name | DELTA |

| Certification | ISO |

| Model Number | 201 304 316L 321 310S 314 347 2205 2507 904L.etc |

| Minimum Order Quantity | 500 kgs |

| Price | 2400 - 3500 USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | T/T, Western Union, L/C |

| Supply Ability | 10 Ton per week |

| Products | BA Stainless Steel Pipe | Grade | 304 316L 321 2205 310S 904L.etc |

|---|---|---|---|

| Standard | ASTM GB EN | Length | 6m Or As Request |

| Diameter | 6 - 219mm Or As Clients Request | Wall Thickness | 0.4 - 8.0mm |

| Type | Seamless Pipe | Service | Cutting |

| Other Shape | Square, Rectangle | ||

| Highlight | ASTM A269 Stainless Steel Pipe |

||

TP304 TP316L Stainless Steel Pipe Seamless Pipe Precison Cold Drawn SS Pipes ASTM A269

Products Specification

|

Product Name

|

SA269 Stainless steel pipe

|

|

Standard

|

ASTM AISI DIN, EN, GB, JIS

|

|

Steel Grade

|

200 Series: 201,202

300 Series: 301,304,304L,316,316L,316Ti,317L,321,309s,310s 400 Series: 409L,410,410s,420j1,420j2,430,444,441,436 Duplex Steel: 904L,2205,2507,2101,2520,2304 |

|

Outer Diameter

|

6-325mm(as required)

|

|

Thickness

|

0.4mm - 10.0mm |

|

Length

|

6m / pcs or custom other fixed length as request

|

|

Technique

|

Seamless/Welded

|

|

Surface

|

pickling finishing, BA , Hairline , polishing |

|

MOQ

|

500 kgs

|

|

Price Terms

|

FOB,CFR,CIF

|

Bright Annealed Stainless Steel Tube (BA tube) is a kind of high-precision stainless steel tube with special heat treatment and surface treatment, which has a smooth, bright appearance and excellent corrosion resistance. The following is a detailed introduction to bright annealed stainless steel pipes:

1. Main Grade of Bright Annealed Stainless Steel Pipe Tube

Bright annealed stainless steel pipe commonly used stainless steel grades include:

Austenitic stainless steel:

304/304L (06Cr19Ni10/022Cr19Ni10)

316/316 (06 cr17ni12mo2 l / 022 cr17ni12mo2)

321 (06Cr18Ni11Ti)

Martensitic or ferrite stainless steel:

430 (10Cr17)

420 (20Cr13)

2. Enforce standards

The production and inspection of bright annealed stainless steel pipes usually follow the following international or national standards:

International standard:

ASTM A269/A270 (Universal Seamless and Welded Austenitic Stainless Steel Pipe)

ASTM A312 (Austenitic Stainless Steel Seamless Welded Pipe)

EN 10305 (Precision Seamless Steel Pipe)

Domestic standard:

GB/T 12771 (Welded stainless steel pipe for fluid transport)

GB/T 14976 (seamless stainless steel pipe for fluid transport)

YB/T 5363 (Bright annealed stainless steel welded steel pipe)

Step 3: Characteristics

High surface finish: through bright annealing treatment (heating and cooling in an oxygen-free or protective atmosphere), the surface is free of oxidation, a mirror or matte effect, roughness (Ra) is usually ≤0.4μm.

Strong corrosion resistance: the annealing process eliminates the processing stress, improves the uniformity of the material and the resistance to intergranular corrosion.

High dimensional accuracy: suitable for occasions with strict tolerances, such as instruments, medical equipment, etc.

Clean and pollution-free: no oil, no residue on the surface, suitable for high clean environment (such as food, semiconductor industry).

4. Application field

- Medical instruments: surgical instruments, medical catheters, implants, etc. (commonly used 316L BA tube).

- Food and beverage industry: pipeline, dairy equipment, brewing equipment, etc.

- Semiconductors and electronics: high purity gas/liquid delivery systems, vacuum chambers.

- Automotive industry: fuel systems, sensor components.

- Home and decoration: high-end furniture, lamps, bathroom accessories (such as 304 BA pipe).

5. Production process

- Cold rolling or cold drawing: Obtain high dimensional accuracy.

- Bright annealing: heating to 1050~1150°C under the protection of hydrogen or nitrogen to avoid surface oxidation.

- Pickling or electrolytic polishing (optional) : Further improve the surface finish.

- Non-destructive testing: ensure that there are no cracks, pores and other defects.

6. The difference with other stainless steel pipes

- Characteristics Bright Annealing Tube (BA) Ordinary Annealing Tube (AP) Pickling Tube (AP)

- Surface specular/matte, no oxide dull, oxide matte, slightly rough

- Excellent corrosion resistance (no decarburization layer) average (need subsequent pickling) good (after pickling)

- Cost higher lower medium

Bright annealed stainless steel pipe with its high cleanliness, corrosion resistance and aesthetics, widely used in the field of hygiene and precision requirements. The selection should match the brand and standard according to the specific working conditions (such as medium, temperature, pressure).

![]()

![]()

![]()

![]()