-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

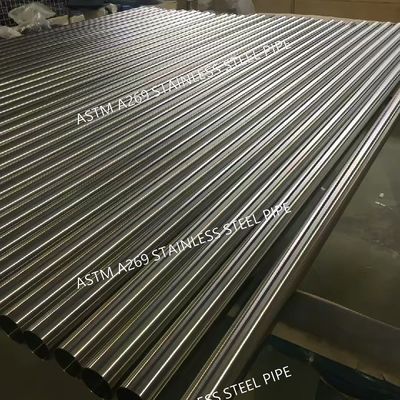

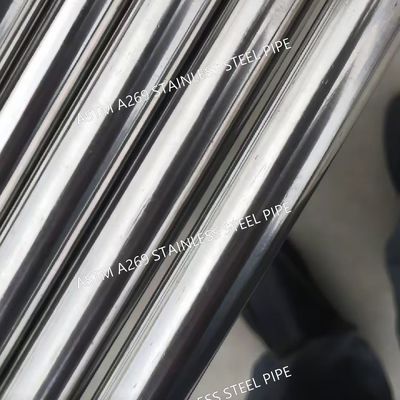

ASTM A269 TP304 Stainless Steel Seamless Pipe BA Bright Anealed Finishing

| Place of Origin | China |

|---|---|

| Brand Name | DELTA |

| Certification | ISO |

| Model Number | 201 304 316L 321 310S 314 347 2205 2507 904L.etc |

| Minimum Order Quantity | 500 kgs |

| Price | 2400 - 3500 USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | T/T, Western Union, L/C |

| Supply Ability | 10 Ton per week |

| Products | BA Stainless Steel Pipe | Grade | 304 316L 321 2205 310S 904L.etc |

|---|---|---|---|

| Standard | ASTM GB EN | Length | 6m Or As Request |

| Diameter | 6 - 219mm Or As Clients Request | Wall Thickness | 0.4 - 8.0mm |

| Type | Seamless Pipe | Service | Cutting |

| Other Shape | Square, Rectangle | ||

| Highlight | TP304 Seamless Stainless Steel Pipe,BA Bright Anealed Stainless Steel Pipe,ASTM A269 Stainless Steel Pipe |

||

ASTM A269 TP304 Stainless Steel Pipe / Seamless Pipe BA Bright Anealed Finishing

Products Specification

|

Product Name

|

Welded Stainless steel pipe

|

|

Standard

|

ASTM AISI DIN, EN, GB, JIS

|

|

Steel Grade

|

200 Series: 201,202

300 Series: 301,304,304L,316,316L,316Ti,317L,321,309s,310s 400 Series: 409L,410,410s,420j1,420j2,430,444,441,436 Duplex Steel: 904L,2205,2507,2101,2520,2304 |

|

Outer Diameter

|

6-325mm(as required)

|

|

Thickness

|

0.4mm - 10.0mm |

|

Length

|

6m / pcs or custom other fixed length as request

|

|

Technique

|

Seamless/Welded

|

|

Surface

|

pickling finishing, BA , Hairline , polishing |

|

MOQ

|

500 kgs

|

|

Price Terms

|

FOB,CFR,CIF

|

Seamless Bright Annealed Stainless Steel Tube Pipe ASTM A269

- Standard:ASTM A269 EN 10217-7

- Material:TP304/304L, TP316/316L other material is also avaliable.

- Type one: Pickling Pipe

- Size: OD:0.23''-80''(5.8-2032mm)

- WT:0.01''-1.125''(0.25-28mm)

ANSI/ASME size as under,

NPS:1/8''-80'' SCH:5/5s,10/10s,20/20s,40/40s,80/80s,120/120s,160/160s acc. to ANSI B36.19/36.10

other standard of size is for ready choice.

Length: according to clients' request.

Standard:JIS DIN GB BS ASTM(ASME) etc.

Surface Finish: Annealed,Polish,Brush etc.

Application:for fluid and gas transport structure and maching.

Packing:Plywood cases or bundles.

Type two:Bright Annealed Tube

Size: OD range:6-50.8mm WT range:0.71-3.68mm Length:6-24m

Standard:ASTM A269, EN 10217-7, etc

Process Method:Weled ,bright annealed.

Surface Finish:Bright Annealed(BA),pickling,bright annealed(BA)&polish

Packing:Plywood cases or bundles.

Bright Annealed stainless steel tube, ASTM A269, ASME SA269 -2015 TP310, 310S, TP316Ti ,TP347, 904L, TP347H, 254Mo

Specification:

- ASME SA213/A213: Standard Specification for Seamless Ferritic and Austenitic Alloy-

- Steel Boiler, Superheater and Stainless Steel Heat Exchanger Tubes.

- ASTM A269 / A269M:Standard Specification for Welded Austenitic Steel Boiler, Superheater

- Heat-Exchanger, and Condenser Tubes.

Other Standard:DIN 17456 , DIN 17458, EN10216-5, GOST 9940-81, GOST 9941-81, JIS-G3463...

Material Grade:

| American Standard | Austenitic Steel: TP304,TP304L,TP304H, TP304N, TP310S,TP316,TP316L,TP316Ti,TP316H, TP317,TP317L, TP321, TP321H,TP347, TP347H,904L… Duplex Steel : S32101,S32205,S31803,S32304,S32750, S32760 Others:TP405,TP409, TP410, TP430, TP439,... |

| Europen Standard | 1.4301,1.4307,1.4948,1.4541,1.4878,1.4550,1.4401,1.4404,1.4571,1.4438, 1.4841,1.4845,1.4539,1.4162, 1.4462, 1.4362, 1.4410, 1.4501 |

| GOST | 08Х17Т,08Х13,12Х13,12Х17,15Х25Т,04Х18Н10,08Х20Н14С2, 08Х18Н12Б,10Х17Н13М2Т,10Х23Н18,08Х18Н10,08Х18Н10Т, 08Х18Н12Т,08Х17Н15М3Т,12Х18Н10Т,12Х18Н12Т,12Х18Н9, 17Х18Н9, 08Х22Н6Т, 06ХН28МДТ |

Size Range:

| Production | Outside Diameter | Wall Thickness |

| Heat Exchanger Tube | 6.00mm to 101.6mm | 0.5mm to 8mm |

Final Finishing

Solution Annealed & Pickled/Bright Annealed.

Type of Tubes:

U-bend & Straight.

Some of the quality tests carried out by us includes:

| Corrosion Test | Conducted only when specially requested by the client |

| Chemical Analysis | Test done as per required quality standards |

| Destructive / Mechanical Testing | Tensile | Hardness | Flattening | Flare | Flange |

| Reverse-bend and Re. flat tests | Carried out in full compliance with relevant standards & ASTM A-450 and A-530 norms, which ensures trouble-free expansion, welding & use at customers end |

| Eddy Current Testing | Done to detect homogeneities in subsurface by using Digital Flaw-mark Testing System |

| Hydrostatic Testing | 100% Hydrostatic Testing carried out according to ASTM-A 450 norms for checking tube leakage, and biggest pressure we can support 20Mpa/7s . |

| Air Under Pressure Test | To check any evidence of air leakage |

| Visual Inspection | After passivation, every single length of tubes & pipes is subjected to thorough visual inspection by trained staff for detecting surface flaws & other imperfections |

Supplementary Testing : Apart from the above mentioned tests, we also carry out on the manufactured products supplementary testing. The tests conducted under this include:

|

|

|

Products Pictures

![]()

![]()

![]()

![]()