-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

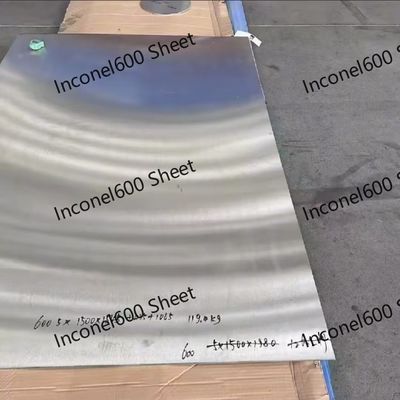

EN 10204-3.1 Certificated Inconel 600 Alloy Plate / Sheet / Strips Thickness 0.5 - 100mm

| Products | Nickel Alloy Plate | Grade | UNS N06600 / Inconel 600 |

|---|---|---|---|

| Thickness | 0.5 - 16.0mm | Width | 1000mm 1219mm 1500mm |

| Standard | ASTM EN | Service | Cutting |

| Loading Port | Shanghai Port | Surface | 2B NO.1 |

| Highlight | Inconel 600 Alloy Plate,100mm Inconel 600 Alloy Plate |

||

EN 10204-3.1 Certificated Inconel 600 Alloy Plate / Sheet / Strips Thickness 0.5 - 100mm

Products Specification

| Product Name | UNS 06600 / Inconel 600 Nickel Alloy Plate |

|---|---|

|

Standard |

ASTM EN DIN GB JIS |

| Thickness |

Cold Rolled: 0.6mm,0.8mm,1.0mm,1.2mm,1.5mm,2.0mm,2.5mm,3.0mm Hot Rolled:4.0mm,5.0mm,6.0mm,8.0mm,10.0mm,12.0mm,14.0mm,16.0mm,20.0mm Forged : 20 - 200mm custom any size as request |

| Standard Size |

Cold rolled Sheet 1219*2438mm Hot rolled Plates 1500*6000mm |

| Main Grade | 600,601,625,718,800,800H,800HT,926,C276,C4,Monel400 K500 904L 254SMO 654SO 317L.etc |

| Service | Laser Cutting any size as request |

| Other Products | Coil, Sheet, Plate, Wire, Round Bar, Square Bar,Pipe,Tube.etc |

Inconel 600 is a nickel-chromium alloy composed primarily of 72% nickel, 14-17% chromium, 6-10% iron, and trace amounts of manganese, silicon, and carbon. This composition provides excellent resistance to oxidation, carburization, and corrosion, particularly in high-temperature environments. The mechanical properties of Inconel 600 include a tensile strength of 70-100 ksi (485-690 MPa), yield strength of 30-80 ksi (210-550 MPa), and elongation of 35-50%. It also maintains its strength and oxidation resistance in temperatures up to 2000°F (1093°C), making it ideal for demanding industrial applications.

Inconel 600 Sheets and Plates Mechanical Properties

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Inconel 600 | 8.47 g/cm3 | 1413 °C (2580 °F) | Psi – 95,000 , MPa – 655 | Psi – 45,000 , MPa – 310 | 40 % |

Inconel 600 Sheets and Plates Chemical Composition

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

| Inconel 600 | 0.15 max | 1.00 max | 0.50 max | 0.015max | 0.50 max | 6.00 – 10.00 | 72.00 min | 14.00 – 17.00 |

DIN 2.4816 Plates , Inconel 600 Plates , Inconel 600 Sheets, Inconel 600 Sheets and Plates , Inconel Alloy 600 Sheets , Nickel Alloy 600 HR SheetsASME SB168 UNS N06600 Cold Rolled Sheet

Inconel 600 Sheets and Plates Equivalent Grade

| Grade | UNS No | Old British | Euronorm | GOST | Japanese JIS | ||

| BS | En | No | AFNOR | ||||

| Inconel 600 | N06600 | NA 13 | NiCr15Fe | 2.4816 | NC15FE11M | МНЖМц 28-2,5-1,5 | NCF 600 |

Inconel 600 sheets and plates offer several advantages, making them ideal for high-performance applications. They exhibit excellent resistance to oxidation, carburization, and corrosion, especially at elevated temperatures, ensuring durability in harsh environments. With high tensile strength and excellent weldability, Inconel 600 is highly reliable in aerospace, chemical, and power generation industries. It also maintains stability and strength in extreme thermal conditions, making it suitable for use in heat exchangers, gas turbines, and furnace components. Additionally, Inconel 600’s resistance to chloride-ion stress corrosion cracking enhances its longevity and performance.

Application Industry of Inconel 600 Sheets and Plates

- Oil and Gas Industry

- Transporting Materials

- Pulp and Paper Industry

- Power Plant Industry

- Dairy and Food Processing

- Heat Exchanger

- Textile Machinery

- Water Waste Projects

- Synthetic Fiber

- Exhaust gas and Exhaust air

- Construction Industry

- Automotive Industry

- Chemical Industry

![]()

![]()

![]()

![]()