-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

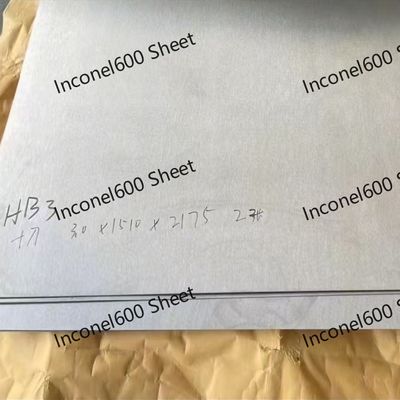

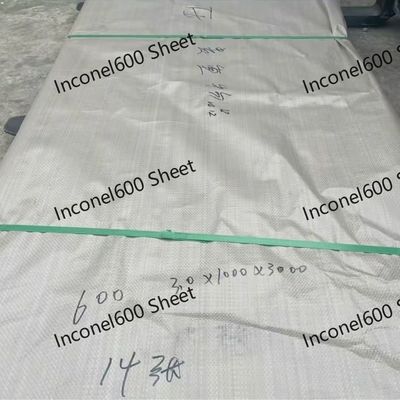

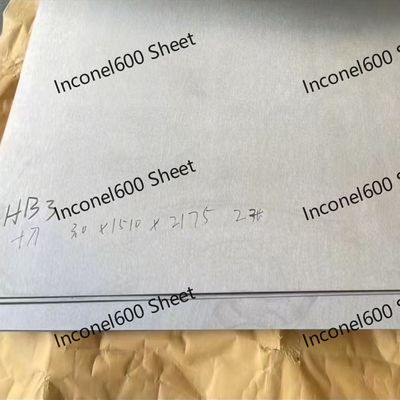

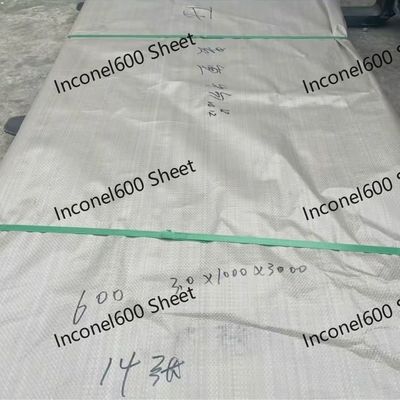

Thickness 1.0mm 1.2mm 1.5mm 2.0mm 2.5mm 3.0mm Inconel 600 /Alloy 600 Sheet / Plate/ Coil

| Products | Nickel Alloy Plate | Grade | UNS N06600 / Inconel 600 |

|---|---|---|---|

| Thickness | 0.5 - 16.0mm | Width | 1000mm 1219mm 1500mm |

| Standard | ASTM EN | Service | Cutting |

| Loading Port | Shanghai Port | Surface | 2B NO.1 |

| Highlight | 2.0mm Inconel 600 Sheet,3.0mm Inconel 600 Sheet,1.0mm Inconel 600 Sheet |

||

Thickness 1.0mm 1.2mm 1.5mm 2.0mm 2.5mm 3.0mm Inconel 600 /Alloy 600 Sheet / Plate/ Coil

Products Specification

| Product Name | UNS 06600 / Inconel 600 Nickel Alloy Plate |

|---|---|

|

Standard |

ASTM EN DIN GB JIS |

| Thickness |

Cold Rolled: 0.6mm,0.8mm,1.0mm,1.2mm,1.5mm,2.0mm,2.5mm,3.0mm Hot Rolled:4.0mm,5.0mm,6.0mm,8.0mm,10.0mm,12.0mm,14.0mm,16.0mm,20.0mm Forged : 20 - 200mm custom any size as request |

| Standard Size |

Cold rolled Sheet 1219*2438mm Hot rolled Plates 1500*6000mm |

| Main Grade | 600,601,625,718,800,800H,800HT,926,C276,C4,Monel400 K500 904L 254SMO 654SO 317L.etc |

| Service | Laser Cutting any size as request |

| Other Products | Coil, Sheet, Plate, Wire, Round Bar, Square Bar,Pipe,Tube.etc |

Inconel 600 Plate or as also referred to by its trade name UNS N06600 is a non-magnetic, highly corrosion resistant nickel based alloy. Reckoned as a conventional engineering grade alloy, Inconel is a good fit for use across a wide temperature range.Inconel 600 is a solution-hardened nickel-chromium alloy. The non-magnetic Inconel 600 Plate is highly resistant to corrosion and oxidation across different stress-induced environments. The superior concentration of nickel in the Inconel Alloy 600 Plate gives these modules exceptional resistance against chloride stress-corrosion cracking. The versatile grade of alloys of the Inconel 600 sheet is designed to withstand temperature range from cryogenic up to 1093 degrees C. These sheets are easily machinable and can be welded readily.

What Properties of Alloy 600 make it Suitable for chemical and food processing

Alloy 600 Plate is designed with a superior concentration of nickel and chromium, giving these modules enhanced corrosion resistance properties. These high-strength modules have excellent resistance against heat in high-temperature systems up to 2100 degrees F. This coupled with their excellent performance in cryogenic temperatures, makes them a good choice in the food and chemical processing industry.

What is best Inconel 600 temperature range and its Density?

Inconel 600 Plate is a solution-hardened module designed for optimum strength and performance. The Inconel 600 temperature range starts from as low as sub-zero/cryogenic temperatures and goes as 1093 degrees C in different environments. Inconel 600 Density is 8.47 g/cc in metric weight.

Inconel 600 Vs 625

- Inconel 600 plate is designed with a chemical concentration of 72% nickel with 14% chromium. A 625 Inconel grade is designed with a chemical composition of 58% nickel, 23% chromium, and 10% of molybdenum. The superior concentration gives the 625 grade higher corrosion resistance properties.

- Inconel 625 plate possesses better strength compared to the 600 Inconel grade.

- The melting range of the 600 grade is higher than Inconel 625 components.

What is ASTM B168?

Usually, components such as plates, sheets, and strips produced from nickel based alloys such as Alloy 600 are made in accordance with ASTM B168. The products made under this particular specification are to be first sampled and prepared, following which they are to be tested for their conformance to not only their chemistry requirements, but also their mechanical as well as their dimensional requirements. In addition to this, the UNS No 6600 plates are also tested to check if they conform to their grain size requirements

ASTM B168 covers the standard specification of

- Nickel- Chromium-Molybdenum-Copper Alloy of (UNS N06235) Sheet, Plate, and Strip

- UNS NO6699 Nickel, chromium, and aluminum alloys

- Nickel- Chromium-Iron Alloys of UNS N06600, N06603, N06601, N06693, N06690, N06045, N06025, and N06696)

- (UNS N06674) Nickel- Iron-Chromium-Tungsten Alloy of

- (UNS N06617) Nickel- Chromium-Cobalt-Molybdenum Alloy

Inconel 600 / UNS N06600 Application

- Nuclear waste reprocessing equipment

- Sour gas production tubes

- Jet Engine exhaust systems

- Aerospace equipment

- Moto exhaust systems

- Chimney Linings

- Chemical Processing

Typical Mechanical Property Ranges Of UNS N06600 Plate

| Element | Density | Melting Point | Yield Strength (0.2%Offset) | Elongation | Tensile Strength |

| Inconel 600 Plate | 8.47 g/cm3 | 1413 °C (2580 °F) | Psi – 45,000 , MPa – 310 | 40 % | Psi – 95,000 , MPa – 655 |

Chemical Compatibility Chart Of Nickel Alloy 600 Plate

| Grade | Fe | Cu | Si | S | Mn | Cr | C | Ni |

| Inconel 600 Plate | 6.00 – 10.00 | 0.50 max | 0.50 max | 0.015max | 1.00 max | 14.00 to 17.00 | 0.15 max | 72.00 min |

ASTM B168 Alloy 600 sheet Equivalent Properties

| STANDARD | AFNOR | WNR Material Number | UNS | BS | EN | GOST | JIS |

| Inconel 600 Plate | NC15FE11M | 2.4816 | N06600 | NA 13 | NiCr15Fe | МНЖМц 28-2,5-1,5 | NCF 600 |

![]()

![]()

![]()

![]()