-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

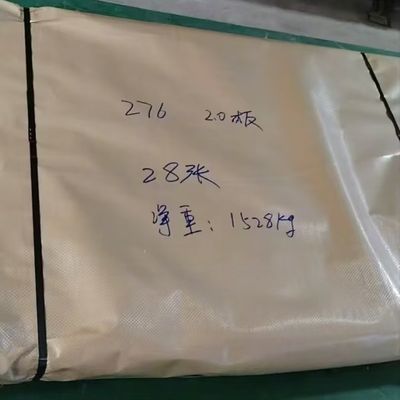

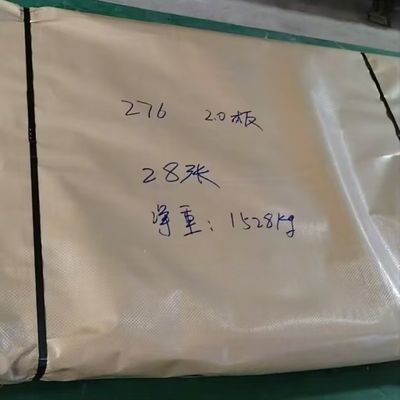

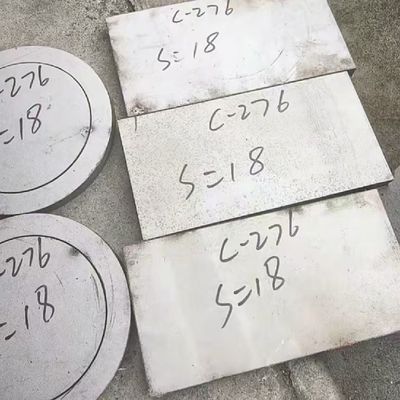

Laser Cutting Hastelloy C276 Nickel Alloy Plate Round Disc Alloy 276 Rings

| Products | Nickel Alloy Plate | Grade | Hastelloy C276 |

|---|---|---|---|

| Thickness | 1.0 - 20.0mm | Width | 1000mm 1219mm 1500mm |

| Standard | ASTM EN | Service | Cutting |

| Loading Port | Shanghai Port | Surface | 2B NO.1 |

| Highlight | Round Disc Nickel Alloy Plate,Alloy 276 Nickel Alloy Plate,Laser Cutting Nickel Alloy Plate |

||

Laser Cutting Hastelloy C276 Nickel Alloy Plate Round Disc , Alloy 276 Rings

Products Specification

| Product Name | Hastelloy C276 Plate |

|---|---|

|

Standard |

ASTM B575 / ASME SB575 |

| Thickness |

Cold Rolled: 0.6mm,0.8mm,1.0mm,1.2mm,1.5mm,2.0mm,2.5mm,3.0mm Hot Rolled:4.0mm,5.0mm,6.0mm,8.0mm,10.0mm,12.0mm,14.0mm,16.0mm,20.0mm Forged : 20 - 200mm custom any size as request |

| Standard Size |

Cold rolled Alloy C276 Sheet 1219*2438mm Hot rolled Alloy C276 Plates 1500*6000mm |

| Service | Laser Cutting any size as request |

| Other Products | Hastelloy C276 Coil,Hastelloy C276 strip,Hastelloy C276 pipe, Hastelloy C276 bar, Hastelloy C276 wire.etc |

Hastelloy C276 sheet metal introduction

Hastelloy C276 is a nickel-based alloy with excellent corrosion resistance and high temperature properties. It belongs to the Hastelloy series and is widely used in strong corrosive environments and high temperature occasions.

Main parameter

Chemical composition (typical value, %) :

- Nickel (Ni): margin

- Chromium (Cr): 14.5-16.5

- Molybdenum (Mo): 15.0-17.0

- Iron (Fe): 4.0-7.0

- Tungsten (W): 3.0-4.5

- Cobalt (Co): ≤2.5

- Manganese (Mn): ≤1.0

- Silicon (Si): ≤0.08

- Carbon (C): ≤0.01

- Phosphorus (P): ≤0.04

- Sulfur (S): ≤0.03

Mechanical properties of Hastelloy C276 Plate

- Tensile strength: ≥690 MPa

- Yield strength: ≥283 MPa

- Elongation: ≥40%

- Hardness: ≤100 HRB

- Physical properties:

- Density: 8.89 g/cm³

- Melting point: 1325-1370 °C

- Thermal expansion coefficient: 11.2μm /m·°C (20-100 °C)

- Thermal conductivity: 10.2W /m·K (100 °C)

- Resistivity: 1.30 μΩ·m

Standard of Hastelloy C276 Plate

- ASTM: ASTM B575

- EN: EN 2.4819

- JIS: JIS NW0276

- GB: GB/T 15007

Size of Hastelloy C276 Plate Sheet we can supply

- Thickness: 0.6mm-100mm

- Width: 1000mm-2000mm

- Length: 2000mm-6000mm

Apply of Hastelloy C276 Plate

- Chemical industry: Used to manufacture reactors, heat exchangers, pipelines, etc.

- Environmental protection project: Used for flue gas desulfurization equipment.

- Oil and gas: Used in offshore platforms and refining equipment.

- Pharmaceutical industry: For high-purity equipment.

- Nuclear industry: Used for nuclear reactor components.

Introduction to laser cutting

Laser cutting is a processing method that uses high energy density laser beam to cut materials. It has the characteristics of high precision, high efficiency and high quality, and is widely used in the cutting of metal and non-metal materials.

Processing range

- Material type: Metal (such as stainless steel, aluminum alloy, titanium alloy, nickel-based alloy, etc.), non-metal (such as plastic, wood, glass, etc.).

- Thickness range: Usually suitable for sheet metal from 0.5mm to 25mm, depending on laser power and material type.

Peculiarity of Hastelloy C276 Plate

- High precision: The cutting accuracy can reach ±0.1mm, suitable for precision machining.

- High efficiency: fast cutting speed and high automation.

- High quality: smooth cutting surface, no need for secondary processing.

- Flexibility: Can cut complex shapes and small holes.

- Non-contact processing: reduce material deformation and tool wear.

Hastelloy C276 sheet is widely used in chemical, environmental, oil and gas, pharmaceutical and nuclear industries due to its excellent corrosion resistance and high temperature properties. As a high-precision and high-efficiency processing method, laser cutting is suitable for cutting a variety of materials, especially for complex shapes and high-precision processing tasks.

![]()

![]()

![]()

![]()