-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

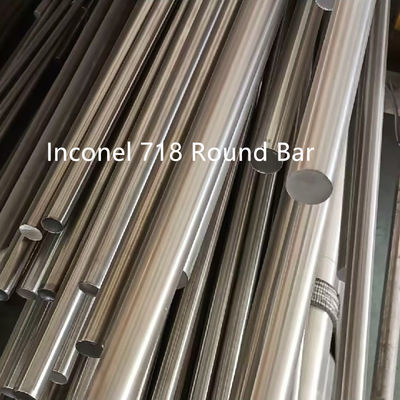

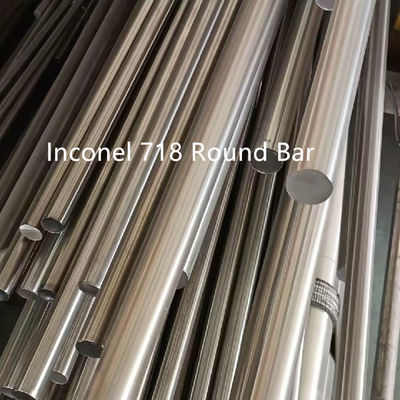

Inconel 718 Round Bar UNS N07718 / 2.4668 Alloy Bright Bar 4 - 50mm

| Products | Nickel Alloy Round Bar | Grade | Inconel 718 |

|---|---|---|---|

| Diameter | 10 - 350mm | Length | Custom Cutting Any Length As Request |

| Standard | ASTM EN | Service | Cutting |

| Loading Port | Shanghai Port | Surface | Black, Bright |

| Highlight | UNS N07718 Round Bar,2.4668 Round Bar,Inconel 718 Round Bar |

||

Inconel 718 Round Bar UNS N07718 / 2.4668 Alloy Bright Bar 4 - 50mm

Products Specification

|

Standard

|

AISI, ASTM, BS, DIN, GB, JIS

|

||

|

Grade

|

Monel series: 400 K500

Inconel series: 600 601 625 718 725 Incoloy series: 800 800H 825 925 Hastelloy series: B,B2,B3,C,C-276,C-4,C-22 Pure: Ni200, Ni201 |

||

|

Specifications

|

Round bar

|

Diameter:4~300mm

|

|

|

Flat bar

|

Thickness

|

1.0~100mm

|

|

|

Width

|

1~1500mm

|

||

|

Square bar

|

Size: 4*4-100*100mm

|

||

|

Length

|

2m, 5.8m, 6m, or as required.

|

||

|

Surface

|

Black, peeled, polishing, bright, sand blast, hair line, etc.

|

||

|

Price Term

|

Ex-work, FOB, CFR, CIF, etc.

|

||

|

Delivery Time

|

Standard size is in stock,prompt delivery or as order's quantity.

|

||

|

Package

|

Export standard package, bundled or be required.

The inner size of container is below: 20ft GP: 5.9m(length) x 2.13m(width) x 2.18m(high)about 24-26CBM 40ft GP: 11.8m(length) x 2.13m(width) x 2.18m(high) about 54CBM 40ft HG: 11.8m(length) x 2.13m(width) x 2.72m(high) about 68CBM |

||

Inconel 718 Round rod introduction

Inconel 718 is a nickel-based superalloy known for its excellent high temperature strength, corrosion resistance and oxidation resistance. It is strengthened by adding niobium and molybdenum, has good aging hardening properties, and is widely used in aerospace, oil and gas, nuclear energy and other fields.

Main parameter of Inconel 718 Round Bar

Chemical composition:

- Nickel (Ni): 50-55%

- Chromium (Cr): 17-21%

- Iron (Fe): margin

- Niobium (Nb): 4.75-5.5%

- Molybdenum (Mo): 2.8-3.3%

- Titanium (Ti): 0.65-1.15%

- Aluminum (Al): 0.2-0.8%

- Carbon (C): 0.08% max

- Manganese (Mn): 0.35% max

- Silicon (Si): 0.35% max

- Copper (Cu): 0.3% max

- Density: 8.19 g/cm³

- Melting point: 1260-1340°C

- Coefficient of thermal expansion: 13.0µm /m°C (20-100°C)

- Thermal conductivity: 11.4 W/m·K (100°C)

- Resistivity: 1.25µΩ ·m (20°C)

Peculiarity of Inconel 718 Round Bar

- High strength: Excellent high temperature strength and creep resistance through age hardening.

- Corrosion resistance: Good corrosion resistance in both oxidizing and reducing environments.

- Oxidation resistance: It has good antioxidant properties at high temperatures.

- Weldability: easy to weld, stable performance after welding.

- Fatigue resistance: It has good fatigue resistance under high cyclic stress.

Property of Inconel 718 Round Bar

Mechanical properties:

- Tensile strength: ≥ 1350 MPa (after age hardening)

- Yield strength: ≥ 1170 MPa (after age hardening)

- Elongation: ≥ 12% (after age hardening)

- Hardness: ≥ 35 HRC (after age hardening)

- High temperature performance: Good mechanical properties at temperatures up to 700°C.

- Low temperature performance: maintain excellent toughness and strength in low temperature environment.

Specification of Inconel 718 Round Bar

- Diameter range: usually 5mm to 300mm

- Length: Usually 1000mm to 6000mm

- Surface treatment: black leather, car, polishing, etc

Standard of Inconel 718 Round Bar

- ASTM: B637

- AMS: 5662, 5663, 5664

- UNS: N07718

- DIN: 2.4668

Advantage of Inconel 718 Round Bar

- Excellent high temperature performance: high strength, oxidation resistance and creep resistance at high temperatures.

- Strong corrosion resistance: suitable for a variety of corrosive environments.

- Easy processing and welding: It can be formed and welded by a variety of processing methods.

- Versatility: Suitable for extreme environments, including high temperature, high pressure and corrosive media.

Apply of Inconel 718 Round Bar

- Aerospace: Engine components (turbine discs, blades, combustion chambers), rocket engine components, high-strength fasteners

- Oil and Gas: downhole tools, valves and pump components, high pressure and high temperature pipelines

- Nuclear energy: nuclear reactor components, heat exchangers

- Chemical: Reactors, heat exchangers, piping systems

- Other: High strength springs, dies and tools

Inconel 718 round rods are widely used in aerospace, oil and gas, nuclear energy and other fields due to their excellent high temperature strength, corrosion resistance and oxidation resistance. Its high strength and good workability, obtained through age hardening, make it an ideal material choice for extreme environments.

![]()

![]()

![]()

![]()