Grade: 304 ,201,430,316

Thickness: 0.5mm – 3.0mm

Width: 1000/1219/1500mm/customized

Length: 6000mm/coil

Film: Double PE/laser PE

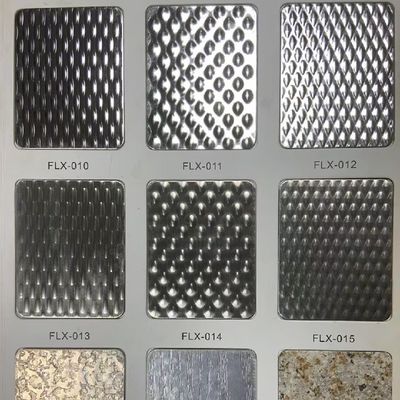

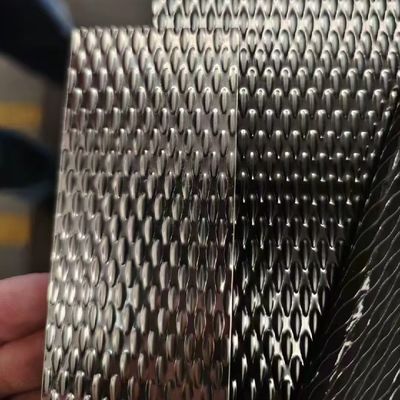

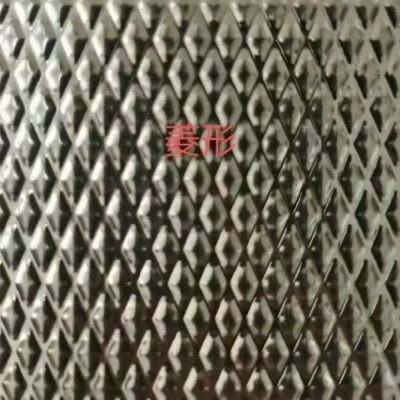

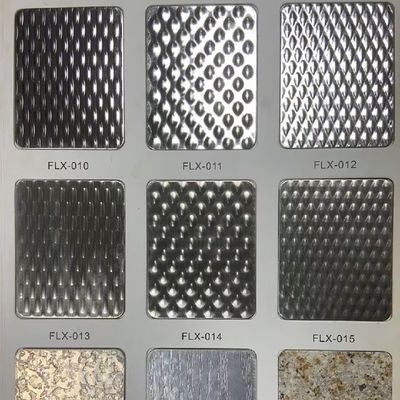

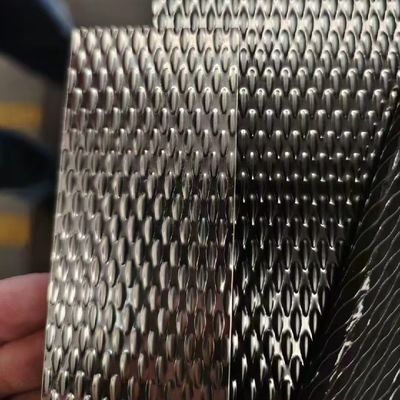

Pattern:

- Leather 2B Mill Finish stainless steel,

- Leather Rose Gold stainless steel,

- Leather BA stainless steel,

- Wood Brass stainless steel,

- Linen BA stainless steel,

- Linen Antique stainless steel,

- Linen Brass stainless steel,

- ICY Bamboo stainless steel,

- Square embossed stainless steel,

- 6WL stainless steel,

- 5WL stainless steel