-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

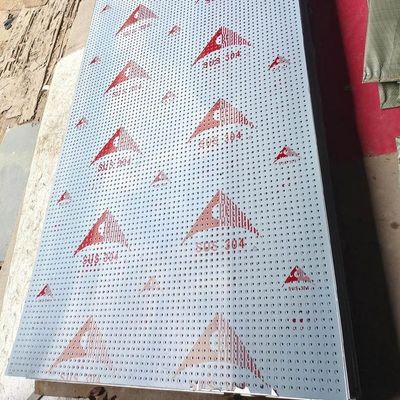

Perforated Stainless Steel Metal Sheet Plate SUS304 SUS316L SUS310S SS Sheet With Holes

| Place of Origin | China |

|---|---|

| Brand Name | TISCO |

| Certification | ISO |

| Model Number | 201 304 304L 310S 316L 317L 321.etc |

| Minimum Order Quantity | 500 kgs |

| Price | 2100 - 3200 USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | T/T, Western Union, L/C |

| Supply Ability | 10 Ton per week |

| Products | Stainless Steel Perforated Sheet | Grade | 304 201 316L 430 410S.etc |

|---|---|---|---|

| Hole Diameter | 1.0 - 20.0mm | Size | 1000*2000mm 1219*2438mm 1500*3000mm |

| Thickness | 0.3 - 3.0mm | Type | Cold Rolled |

| Surface | 2B | Application | Industrial |

| Packing | Wooden Pallets | ||

| Highlight | SUS304 Stainless Steel Sheet,Perforated Stainless Steel Sheet,SUS316L Stainless Steel Sheet |

||

Perforated Stainless Steel Metal Sheet & Plate SUS304 SUS316L SUS310S SS Sheet With Holes

Products Specification of our Perforated Metal Sheet

| Name | Perforated Metal Sheet |

| Material | SS 304 316L 201;Aluminum;Aluminum alloy;Iron;Gavanized steel;Q235,Q195;Mn steel |

| Hole Diameter | 0.1-30mm (0.1-0.4mm is etching hole;More than 30mm is laser cutting) |

| Size | Normal size is 1x2m 1.22x2.44m 1.5x3m (Other size we can customize.) |

| Thickness | 0.1-10mm |

| Coating | PVC Coating; Powder spraying; Galvanized Coating; |

| Applications | Industrial proccesing, Machinery, Food processing, Building & Constructions, Agriculture,Communication industries, automotive industries, hardward&household industries. |

| Hole shape | Round perforation, Square perforation, Rectangular, Hexagonal perforation, Slots perforation |

| Angle degree | 45°;60°;90° |

Pattern of Perforated Sheet

![]()

Perforated stainless steel is crafted by cutting, punching, or stamping to create precise patterns of holes or apertures. It serves both functional purposes, like filtration and ventilation, and aesthetic roles, such as architectural detailing.

Beyond their visual appeal, perforated steel sheets offer various practical benefits. They allow light to filter through while providing an effective means of screening. Additionally, these sheets are used for sound attenuation, contributing to a quieter and more comfortable environment. In architecture, perforated steel sheets are commonly employed as decorative elements. They also play a crucial role in sectors such as acoustics, food and beverage processing, chemicals, and energy, where they are used for efficient fluid filtration.

What to Consider When Choosing Perforated Steel Sheets

Application

When selecting a perforated steel sheet, the primary consideration is the intended application of the finished product. Understanding the specific requirements and functions of the product significantly influences other factors in the decision-making process.

Material

There are several base substrates used for perforated materials, each offering distinct properties that make them suitable for different uses. While there are options provided by various suppliers, some of the most commonly used materials include:

- Steel (including cold-rolled, hot-rolled, galvanized, aluminized, and pre-painted varieties) (e.g., hot-rolled pickled, cold-rolled, galvanized, aluminized, and pre-painted)

- Stainless Steel (e.g., protective film-coated, 400-series, T304, and T316)

Hole Sizes

Perforated steel sheets come with a variety of hole sizes and shapes. Consequently, the cost is affected by factors such as the thickness and hardness of the base material, the dimensions and spacing of the holes, as well as the production expenses.

Perforated Sheets Cut to Size

Perforated stainless steel sheets come in various dimensions, with the common sizes being listed below:

- Thickness 0.45mm up to 3mm

- Length 1829mm up to 2438mm

Manufacturing Process of Perforated Steel Sheets

Perforated stainless steel products are crafted from 15 distinct grades, each offering resistance to bacteria, rust, and corrosion. These grades come in various finishes including matte, satin, brushed, reflective, rough, and abrasive. The perforations can be round, square, oval, triangular, diamond, hexagonal, slot, star-shaped, or other custom designs, allowing for the creation of intricate and visually appealing patterns.

There are two primary methods for perforating stainless steel sheets, depending on the complexity of the design. Both methods begin with feeding the stainless steel sheets into a punching press:

- All-cross-perforated punching presses are used for straightforward, repetitive patterns that span the entire sheet.

- The thin stainless steel sheet is punctured by these steel sheets shaping machines' rams, which are shaped in the required pattern.

- A sectional two-axis punching press is used to create patterns and designs that are intricate, one-of-a-kind, and customized.

![]()

![]()

![]()

![]()