-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

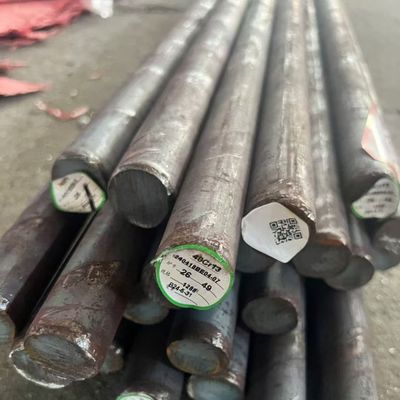

Hot Rolled Stainless Steel Round Bar Diameter 10 - 350mm 410 420 431

| Products | Stainless Steel Round Bar | Grade | 410 420 431 440 |

|---|---|---|---|

| Diameter | 10- 350mm | Length | 6000mm Or Custom Cutting Any Length As Request |

| Standard | ASTM EN | Service | Cutting |

| Loading Port | Shanghai Port | Surface | Black, Bright |

| Highlight | 431 Stainless Steel Round Bar,350mm Stainless Steel Round Bar,420 Stainless Steel Round Bar |

||

Hot Rolled Stainless Steel Round Bar Diameter 10 - 350mm Free Cutting Any Length 410 420 431

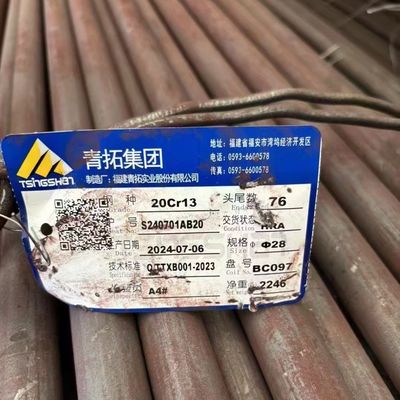

X20Cr13 is a kind of martensitic stainless steel. Commonly used in the production of knives, blades, & other cutting tools. It is a low-carbon alloy that contains 13% chromium. Also composed of small amounts of other elements such as carbon, manganese, and silicon. These elements help to enhance its strength, ductility, & machinability.

Tuolian supply X20Cr13 grade in a wide range of forms, including bars, rods, plates, sheets, tubes, forgings, castings, pipes, wires, etc. Specify your sizes and thicknesses, and we will provide them right away.

All products are also highly economical, due to our high-quality materials and low production costs. We are equipped with the latest technologies and processes, thus, we ensure fast and accurate production.

| Size | Round | Dia 0.1-500mm |

| Plate/Flat/Block | Thickness 0.3mm-200mm |

|

| Width 1mm-2500mm |

||

| Heat treatment | Annealed ; Solid Solution | |

| Surface condition | Black; Peeled; Polished; Machined;Sand blast etc | |

| Delivery condition | Forged; Hot rolled; Cold drawn | |

| Test | Tensile strength, Yield strength, elongation, area of reduction, impact value, hardness, grain size, ultrasonic test, US inspection, magnetic particle testing, etc. | |

| Payment terms | T/T;L/C;/Money gram/ Paypal | |

| Trade terms | FOB; CIF; C&F; etc.. | |

| Delivery time | 30-45 days | |

| Application | AISI420 stainless steels are used in Shear blades,needle valves, surgical equipment, cutlery | |

Chemical Composition of X20Cr13 Stainless Steel

| Element | Percentage |

| Carbon | 0.16 – 0.22% |

| Chromium | 12.00 – 14.00% |

| Manganese | 1.00% max |

| Phosphorus | 0.04% max |

| Sulfur | 0.03% max |

| Silicon | 1.00% max |

Heat Treatment Details

| Treatment | Temperature Range | Purpose |

| Annealing | 750-800°C | Soften the steel and improve machinability |

| Quenching | 950-1050°C | Harden the steel and improve strength |

| Tempering | 150-250°C | Reduce brittleness and improve toughness |

| Stress Relieving | 250-400°C | Remove internal stresses and improve dimensional stability |

| Cold Working | N/A | Increase strength and hardness through plastic deformation |

| Hot Working | 1100-900°C | Shape the steel through forging, rolling, or extrusion |

Equal Grade of X20Cr13 Stainless Steel

| Standard | Grade |

| AISI | 420 |

| ASTM | A276, A314, A580 |

| EN | 1.4021, X20Cr13, X30Cr13 |

| JIS | SUS420J1, SUS420J2 |

| GB | 20Cr13, 30Cr13 |

Application of X20Cr13 Stainless Steel

- Food processing equipment

- Pharmaceutical processing equipment

- Chemical processing equipment

- Pulp and paper production equipment

- Textile processing equipment

- Heat resistant components

- Automotive exhaust systems

- Kitchen sinks, Cutlery, Hand tools

- Oil and gas processing equipment

- Automobile trim & grills

- Desalination Plants

- Fasteners, Valves, Boilers

![]()

![]()

![]()

![]()