-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

ASME SB-265 Standard Specification For Titanium And Titanium Alloy Sheet And Plate

| Place of Origin | China |

|---|---|

| Brand Name | DELTA |

| Certification | ISO |

| Model Number | GR1 GR2 GR3 GR4 GR5 GR7 |

| Minimum Order Quantity | 500 kgs |

| Price | 40-45 USD/Kg |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 3 Ton per week |

| Products | Nickel Bars | Grade | GR1 GR2 GR3 GR4 GR5 GR7 |

|---|---|---|---|

| Thickness | 0.4-30.0mm | Length | Custom Any Length As Request |

| Standard | ASTM EN | Service | Cutting |

| Loading Port | Shanghai Port | Surface | Pickled , Bright |

| Highlight | ASME SB-265 Titanium Plate,ASME SB-265 Titanium Sheet,Titanium Alloy Sheet Plate |

||

ASME SB-265 | Standard Specification for Titanium and Titanium Alloy Sheet and Plate

| Grade | TA1, TA2, TA3, TA4, TA10, TA15, TA17, GR1, GR2, GR3, GR4, GR5, GR7, GR9, GR11, GR12 |

| Size | T(3.0mm~120mm)*W(800mm~2200mm)*L T(0.4mm~3mm)*W(1500mm max)*L |

| Standard | ASTM B 265, ASME SB265 AMS491 |

| Application | Chemical, industry, sports etc. |

| Feature | High corrosion resistance, low density, good thermal stability |

| Surface | Bright, Polished, Pickling, Acid cleaning, Sandblasting |

| Quality and test | Hardness test, Bending test, Hydrostatic etc. |

| Finish | Roll-up(Hard) |

| Surface | Polished |

AVAILABLE SIZES:

- Sheet is 0.3mm to 4.1mm thick, up to 1500mm width cold roll

- Plate is 4.1 mm to 100mm thick, up to 3000mm width hot roll

PROCESSING

Hot rolling and cold rolling

PROCESSING STANDARD:

ASME SB/B265, AMS 4911, AMS 4919, AMS 4914, ASTM F67, ASTM F136, ASTM F1341, ISO 5832-2, MIL-T-9046

EXAMPLE APPLICATIONS:

Fire wall, driver protection, valve covers, bell housings, driveshaft tunnels, brake backing plates, heat shields, rocker shaft stands, jewelry etc

| STANDARD | CHEMICAL COMPOSITION (weight %, max or range) | MECHANICAL PROPERTIES (min) | |||||||||||||

| ASTM B265 | UNS No |

N | C | H | Fe | O | Al | V | Pd | Mo | Ni | Tensile | Yield | El. | Red. |

| Mpa | Mpa | % | % | ||||||||||||

| GR 1 | R50250 | 0.03 | 0.08 | 0.015 | 0.2 | 0.18 | 240 | 138 | 24 | 30 | |||||

| GR 2 | R50400 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | 345 | 275 | 20 | 30 | |||||

| GR 3 | R50550 | 0.05 | 0.08 | 0.015 | 0.3 | 0.35 | 450 | 380 | 18 | 30 | |||||

| GR 4 | R50700 | 0.05 | 0.08 | 0.015 | 0.5 | 0.4 | 550 | 483 | 15 | 25 | |||||

| GR 5 | R56400 | 0.05 | 0.08 | 0.015 | 0.4 | 0.2 | 5.5-6.75 | 3.5-4.5 | 895 | 828 | 10 | 25 | |||

| GR 7 | R52400 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | 0.12-0.25 | 345 | 275 | 20 | 30 | ||||

| GR 9 | R56320 | 0.03 | 0.08 | 0.015 | 0.25 | 0.15 | 2.5-3.5 | 2.0-3.0 | 620 | 483 | 15 | 25 | |||

| GR 12 | R53400 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | 0.2-0.4 | 0.6-0.9 | 483 | 345 | 18 | 25 | |||

| GR 23 | R56401 | 0.03 | 0.08 | 0.0125 | 0.25 | 0.13 | 5.5-6.5 | 3.5-4.5 | 828 | 759 | 10 | 15 | |||

| TITANIUM MATERIALS SUPPLY SCOPE | ||||||||||

| TITANIUM GRADE | UNS NO. | WIRE | BAR | SHEET | PLATE | TUBE | PIPE | FITTING | FORGING | FASTENER |

| Ti Grade 1 | R50250 | √ | √ | √ | √ | √ | √ | X | √ | √ |

| Ti Grade 2 | R50400 | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| Ti Grade 3 | R50550 | √ | √ | √ | √ | X | X | X | √ | √ |

| Ti Grade 4 | R50700 | √ | √ | √ | √ | X | X | X | √ | √ |

| Ti Grade 5 (6Al 4V) | R56400 | √ | √ | √ | √ | X | X | X | √ | √ |

| Ti Grade 7 (0.2Pd) | R52400 | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| Ti Grade 9 (3Al 2.5V) | R56320 | √ | √ | √ | √ | √ | X | X | √ | √ |

| Ti Grade 11 | R52250 | √ | √ | √ | √ | √ | √ | X | √ | √ |

| Ti Grade 12 (0.3Mo 0.8Ni) | R53400 | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| Ti Grade 17 | R52252 | X | √ | √ | √ | √ | √ | X | √ | √ |

| Ti Grade 23 (6Al 4V Eli) | R56401 | √ | √ | √ | √ | X | X | X | √ | √ |

| Notes 1) √-Available, X-Unavailable | ||||||||||

| Notes 2) For other grades like Ti6Al2Sn4Zr2Mo, Ti6Al6V2Sn, Ti8Al1Mo1V, Ti6Al2Sn4Zr6Mo, Ti15V3Cr3Sn3Al, please contact us for details. | ||||||||||

| Notes 3) It may differs a little for materials in different sizes, please also contact us. | ||||||||||

Titanium and Alloy Products

| Product name | Specifications |

| Titanium Rod & Bar & Ingots | Ф3mm~Ф1020mm,the maximum weight is up to 12t |

| Titanium Slab | (80~400)mm×(~1500)mm×(~2600)mm |

| Titanium Forgings | Weight per piece≤2000kg |

| Titanium Hot-rolled plates | (4~100)mm×(800~2600)mm×(2000~12000)mm |

| Titanium Cold-rolled Sheet | (0.01~4.0)mm×(800~1560)mm×( ~6000) mm |

| Titanium Foil / Strips | (0.01~2.0)mm×(800~1560)mm×L |

| Titanium Tubes / Pipes | Ф(3~114)mm×( 0.2~5)mm × (~15000)mm |

| Standards | GB,GJB,ASTM,AMS,BS,DIN,DMS,JIS,ГОСт |

| Titanium Grade |

|

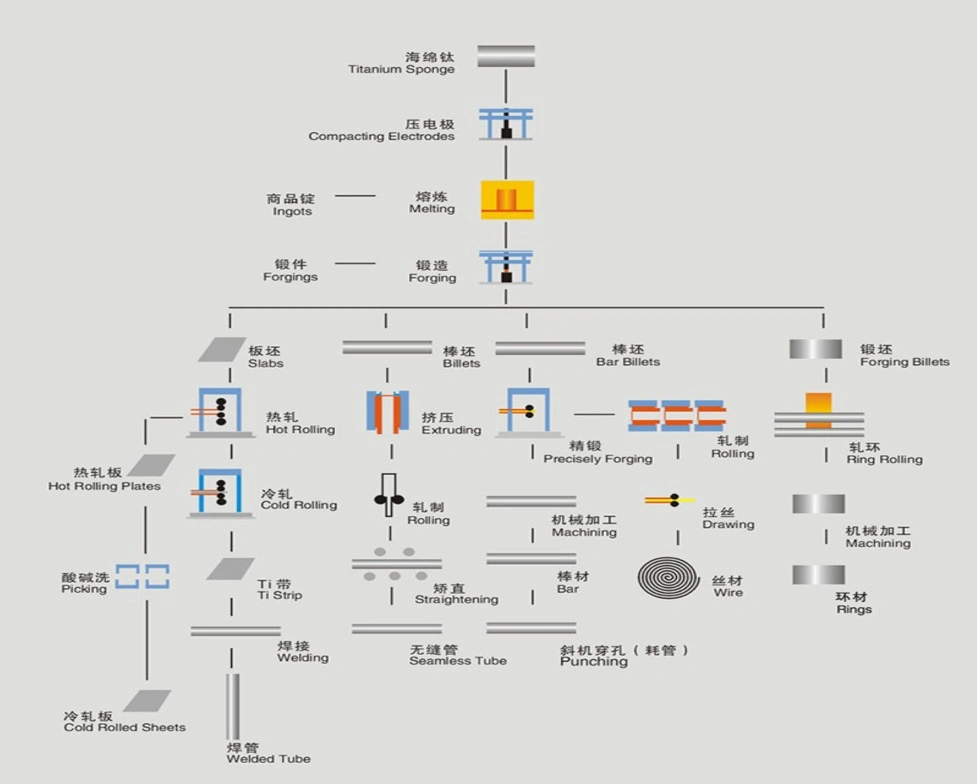

Titanium Production Process

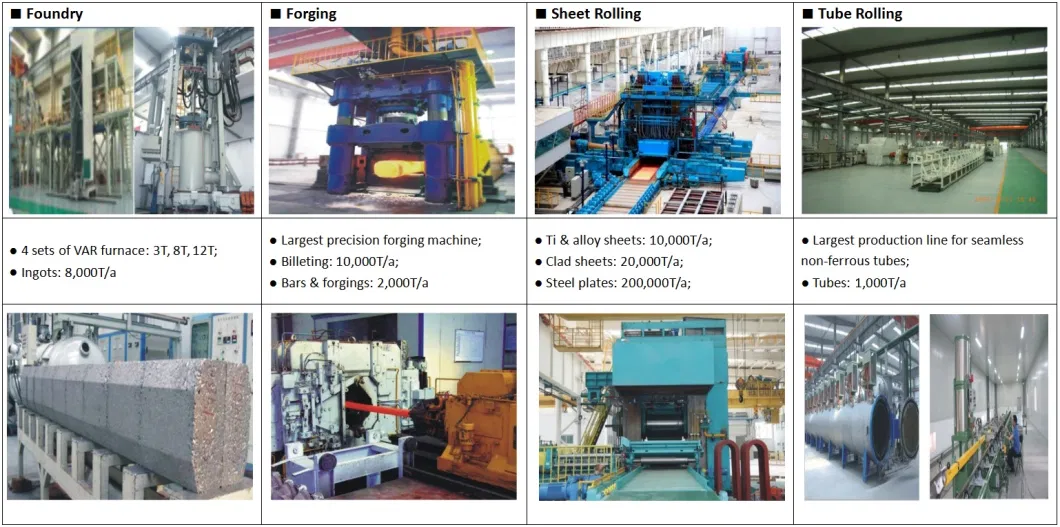

Titanium Production Equipment

Welcome to conact us for titanium inquiry

![]()

![]()

![]()

![]()