-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

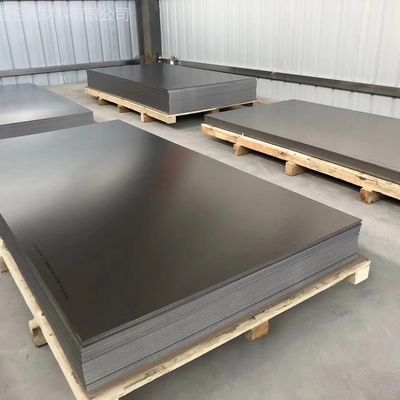

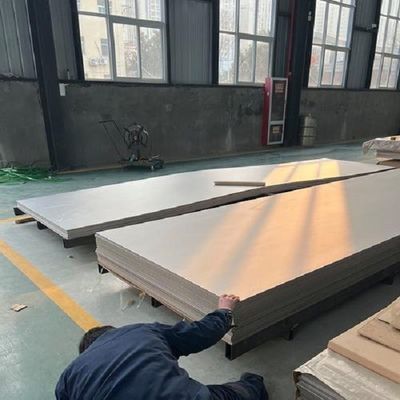

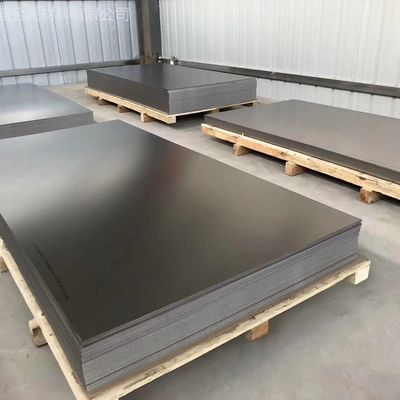

ASTM B265 GR1 Titanium Plate Thickness 0.4 - 30.0mm TA0 Plate Custom Cutting Any Size

| Place of Origin | China |

|---|---|

| Brand Name | DELTA |

| Certification | ISO |

| Model Number | GR1 GR2 GR3 GR4 GR5 GR7 |

| Minimum Order Quantity | 500 kgs |

| Price | 40-45 USD/Kg |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 3 Ton per week |

| Products | Nickel Bars | Grade | GR1 GR2 GR3 GR4 GR5 GR7 |

|---|---|---|---|

| Thickness | 0.4-30.0mm | Length | Custom Any Length As Request |

| Standard | ASTM EN | Service | Cutting |

| Loading Port | Shanghai Port | Surface | Pickled , Bright |

| Highlight | ASTM B265 GR1 Titanium Plate,30.0mm Titanium Plate,TA0 Titanium Plate |

||

ASTM B265 GR1 Titanium Plate Thickness 0.4 - 30.0mm TA0 Plate Custom Cutting any Size

| Grade | TA1, TA2, TA3, TA4, TA10, TA15, TA17, GR1, GR2, GR3, GR4, GR5, GR7, GR9, GR11, GR12 |

| Size | T(3.0mm~120mm)*W(800mm~2200mm)*L T(0.4mm~3mm)*W(1500mm max)*L |

| Standard | ASTM B 265, ASME SB265 AMS491 |

| Application | Chemical, industry, sports etc. |

| Feature | High corrosion resistance, low density, good thermal stability |

| Surface | Bright, Polished, Pickling, Acid cleaning, Sandblasting |

| Quality and test | Hardness test, Bending test, Hydrostatic etc. |

| Finish | Roll-up(Hard) |

| Surface | Polished |

ASTM B265 | ASME SB265 | ASTM F67 | ISO 5832-2 | 3.7025 | UNS R50250

Pure titanium Grade 1 is characterized by very good ductility and, as a result, very good cold formability, which makes the material suitable for deep drawing. Titanium Grade 1 is known for its excellent general and seawater corrosion resistance and offers high corrosion resistance in oxidizing, neutral and mildly reducing media (solutions) including chlorides.

Titanium’s low density (about half that of nickel-based alloys), high strength-to-weight ratio and corrosion resistance make it an ideal material for many corrosive chemical environments.

Characteristics Titanium Grade 1 | ASTM B265 | ASTM F67

Chemical composition - limits in % (ASTM B265 latest edition)

| Ti | Rest |

| Fe | max. 0,20 |

| O | max. 0,18 |

| C | max. 0,08 |

| N | max. 0,03 |

| H | max. 0,015 |

Physical constants and thermal properties

| Density | 4,51g/cm² |

| Melting point | 1670°C |

| Beta transus temperature | 888 ± 4°C |

| Thermal conductivity at 20°C | 16 W/ m°C |

Typical mechanical properties (at room temperature for ASTM B265)

| Yield strength | min. 138, max. 310 MPa |

| Tensile strength | min. 240 MPa |

| Elongation | min. 24% |

Equal grade of Titanium Plate

| GB | ASTM | JIS | DIN | ΓOCΓ |

| TA0 | GR.1 | 1Class | 3.7025 | BT1-00 |

| TA1 | GR.2 | 2Class | 3.7035 | BT1-0 |

| TA2 | GR.3 | 3Class | 3.7055 | - |

| TA3 | GR.4 | 4Class | 3.7065 | - |

| TA6 | - | - | - | BT5 |

| TA7 | GR.6 | - | 3.7115 | BT5-1 |

| TA9 | GR.7 | 12Class | 3.7235 | - |

| TA10 | GR.12 | - | 3.7105 | - |

| TC1 | - | - | - | OT4-1 |

| TC2 | - | - | - | OT4 |

| TC4 | GR.5 | 60Class | 3.7165 | BT6 |

| TC6 | - | - | - | BT3-1 |

| TC10 | AMS Ti-662 | - | 3.7175 | - |

| TC11 | - | - | - | B19 |

Application of Titanium Plate

1. Aerospace Field: Renowned for its high strength, low density, and excellent corrosion resistance, titanium stands as an indispensable asset in aerospace innovations. It plays a pivotal role in the fabrication of structural components for aircraft, rockets, and satellites, encompassing fuselages, engine parts, and fuel tanks.

2. Medical Field: Celebrated for its exceptional biocompatibility, titanium harmonizes seamlessly with human tissues, posing no adverse reactions. This attribute has cemented its extensive use in the medical industry, where it becomes the cornerstone for creating artificial joints, dental implants, pacemaker casings, and a myriad of other crucial medical devices.

3. Chemical Field: Titanium and its alloys shine in the chemical industry, revered for their unmatched corrosion resistance. They are quintessential in constructing chemical reactors, storage reservoirs, pipelines, pumps, and corrosion-resistant materials for marine engineering.

4. Sports Equipment Field: With its lightweight yet robust characteristics, titanium is the material of choice for high-end sports equipment. It finds its place in the crafting of premium bicycle frames, golf clubs, fishing rods, and an array of other elite sporting goods.

5. Other Fields: Beyond these prominent sectors, titanium graces the realm of luxury consumer products, including exquisite jewelry, sleek eyeglass frames, and sophisticated watches. Furthermore, it is a favored material in the electronics, power, and communications industries.

In summary, the exceptional properties of titanium facilitate its extensive application across numerous industries. As technological advancements surge and material standards ascend, the horizons for titanium applications are poised to expand even further.

FAQ

A: Our standard delivery times are exceptionally prompt, typically ranging from 5-10 days for stock items. For custom orders, anticipate a delivery window of 45-90 days, dependent on your specific order volume.

Q:Do you provide samples? Are they free or do they come with an extra charge?

A: We are delighted to offer samples at no cost, though the expense of shipping is the responsibility of the recipient.

Q: What are your terms of payment?

A: Our payment terms require a 30% T/T upfront, with the balance due prior to shipment or through BL at sight for your convenience.

Q: Can you produce the products according to my own drawings?

A:Absolutely, we are capable of manufacturing products tailored to your precise specifications as per your drawings, ensuring complete satisfaction.

Q: How does your factory do regarding quality control?

A:Quality stands at the forefront of our priorities. We rigorously uphold quality control measures throughout the entire production process, from commencement to completion, guaranteeing superior product standards.

Q: Can I request to change the form of packaging and transportation?

A:Yes, we offer flexibility in packaging and transportation methods, adapting as per your requests,

although you will need to cover any additional costs and differences that arise in the process.

Q: How does your factory do regarding quality control?

A:Quality is paramount. We maintain stringent quality control protocols from inception to finalization of production.

Q: How long is the delivery time?

A: Our delivery timeframe spans 10-20 working days following payment confirmation.

Should your order be urgent, we have the capacity to expedite our production process to meet your needs.

Q: What is your Payment?

A: For your convenience, payment options include 100% T/T in advance, Western Union for smaller orders,

or 30% T/T with the remaining 70% due prior to shipment.

For larger orders, we offer 100% Irrevocable LC at sight.

Q: Can you make DDQ (Deep Drawing Quality)?

A: Certainly, we manufacture materials suitable for deep drawing applications such as stainless steel pots, sinks, and bowls. Inform us of your intended use, and we will tailor the mechanical properties to fulfill your specifications.

Q: How to get a sample?

A: We provide samples for your evaluation and testing. For small samples, they are available at your expense.

Q: How to visit your company?

A: Our facility is located in Wuxi Jiangning. If you wish to visit us, please reach out, and we will coordinate your visit.

![]()

![]()

![]()

![]()