-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

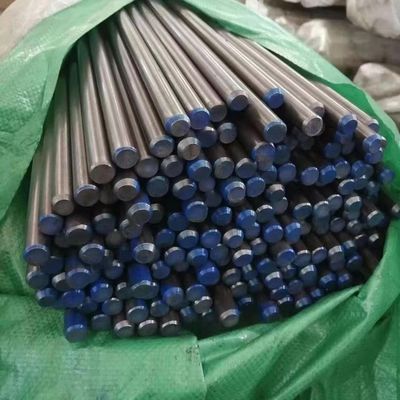

ASTM B160 UNS N02201 Nickel Round Bar Diameter 4 - 200mm HR CR Nickel 201 Alloy

| Products | Nickel Bars | Grade | UNS N02201 / Alloy 201 |

|---|---|---|---|

| Diameter | 4 - 200mm | Length | Custom Any Length As Request |

| Standard | ASTM EN | Service | Cutting |

| Loading Port | Shanghai Port | Surface | Bright |

| Highlight | HR CR Nickel Round Bar,UNS N02201 Nickel Round Bar,ASTM B160 Nickel Round Bar |

||

ASTM B160 UNS N02201 Nickel Round Bar Diameter 4 - 200mm HR CR Nickel 201 Alloy

Products Specification

| Products Name | UNS N02201 / Nickel 201 Bars |

| Standard | ASTM B160 |

| Diameter | 4 - 200mm |

| Type | hot rolled , cold drawn |

| Length | 1m 2m 3m or custom any length as request |

| Other Shape | Pipe, sheet , plate , strip, square , hexagonal,wire |

| MOQ | 50 kgs |

| Loading Port | Shanghai Port |

| Packing | Wooden box |

| Deliver time | 4 - 15 days |

Introduce of Nickel 201 / UNS N02201

Nickel 201 alloy is a commercially pure wrought alloy having properties similar to that of nickel 200 alloy, but with a lower carbon content to avoid embrittlement by inter-granular carbon at high temperatures.

It is resistant to acids and alkalis, and dry gases at room temperature. It is also resistant to mineral acids depending on the temperature and concentration of the solution.

Characteristics of Nickel 201

- Good resistance to corrosion in acids and alkalis and is most useful under reducing conditions.

- Outstanding resistance to caustic alkalis up to and including the molten state.

- In acid, alkaline and neutral salt solutions the material shows good resistance, but in oxidising salt solutions severe attack will occur.

- Resistant to all dry gases at room temperature and in dry chlorine and hydrogen chloride may be used in temperatures up to 550C.

- Resistance to mineral acids varies according to temperature and concentration and whether the solution is aerated or not. Corrosion resistance is better in de-aerated acid.

- Virtually immune to inter granular attack above 315C, chlorates must be kept to a minimum.

Chemical Composition of UNS N02201

|

|

Ni |

Mn |

C |

Si |

Fe |

Cu |

S |

|---|---|---|---|---|---|---|---|

|

Max |

|

0.35 |

0.02 |

0.35 |

0.40 |

0.25 |

0.01 |

|

Min |

99.0 |

|

|

|

|

|

|

Physical Properties of Alloy 201

| Density | 8.9 g/cm cube |

| Specific Heat | 440 J/kg K |

| Electrical Resistivity | 8.5 micro ohms cm |

| Curie Temperature | 358 C |

| Melting Range | 1435-1445 C |

| Thermal Expansion | (106K) 14.3 (20-300 C) |

Equal Standard Specification of Alloy 201

- ASME SB-160 – SB 163

- SAE AMS 5553

- DIN 17740

- DIN 17750 - 17754

- BS 3072-3076

- ASTM B 160 - B 163

- ASTM B 725

- ASTM B730

Application of Nickel 201 Products

- Manufacture and handling of sodium hydroxide, particularly at temperature above 300C.

- Production of viscose rayon. Manufacture of soap.

- Analine hydrochloride production and in the chlorination of aliphatic hydrocarbons such as benzene, methane and ethane.

- Manufacture of vinyl chloride monomer.

- Reactors and vessels in which fluorine is generated and reacted with hydrocarbons.

![]()

![]()

![]()

![]()