-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

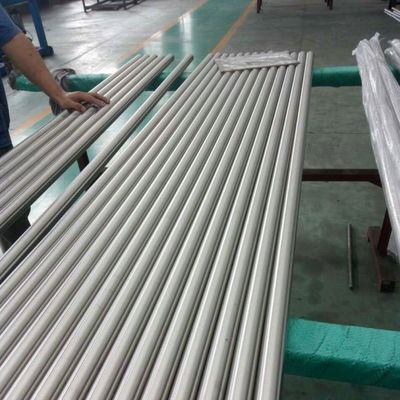

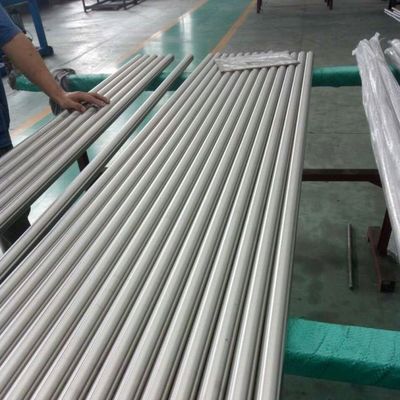

Alloy 200 UNS N02200 Pure Nickel Bar Bright Bar Diameter 4 - 200mm Ni Bars

| Products | Nickel Bars | Grade | Nickel Bar |

|---|---|---|---|

| Diameter | 4 - 200mm | Length | Custom Any Length As Request |

| Standard | ASTM EN | Service | Cutting |

| Loading Port | Shanghai Port | Surface | Bright |

| Highlight | UNS N02200 Pure Nickel Bar,Alloy 200 Pure Nickel Bar,200mm Pure Nickel Bar |

||

Alloy 200 (UNS N02200) Pure Nickel Bar Bright Bar Diameter 4 - 200mm Ni Bars

Description

Nickel 200 is a wrought commercially pure nickel product. The alloy provides highly ductile mechanical properties across a wide temperature range and good corrosion resistance in neutral to moderately reducing environments. In the annealed condition, the alloy possesses the approximate strength of mild steel.

The nickel alloys are readily fabricated by standard fabrication practices. The materials are covered by a variety of specifications and are assigned maximum allowable stresses in the ASME Boiler and Pressure Vessel Code. Nickel 200 is ferromagnetic and provides high thermal and electrical conductivity in comparison to nickel base alloys, stainless and low alloy steels.

Because long term exposures of Nickel 200 in the 800 to 1200°F range can result in precipitation of a carbon containing phase and loss of ductility, the alloy is not recommended for service above 600°F.

Chemical Composition

Chemical Composition (wt%) limits as specified in ASTM B160*

| Carbon | 0.10 | Manganese | 0.50 |

| Nickel | 20.00-23.00 | Silicon | 0.015 |

| Iron | 58.00 min | Sulfur | 0.015 |

Physical Properties

Physical properties for Nickel 200

| Density, lb/in3 | 0.322 |

| Modulus of Elasticity, psi | 30.0 x 106 |

| Coefficient of Thermal Expansion, 68-212˚F, /˚F | 7.4 x 10-6 |

| Thermal Conductivity, Btu/ft hr ˚F | 38.8 |

| Specific Heat, Btu/lb ˚F | 0.106 |

| Electrical Resistivity, Microhm-in | 21.6 |

Mechanical Properties

Mechanical property requirements for annealed bar product as specified in ASTM B160

| Yield Strength, min. (ksi) | 15 |

| Tensile Strength, min. (ksi) | 55 |

| Elongation, min. (%) | 40 |

Standards

Typical standards for Nickel 200

| ASTM B160 |

| ASME SB160 |

Nickel Alloy 200 Equivalents

- ASME SB-160 – SB-163

- DIN 17740

- DIN 17750-17754

- BS 3072-3076

- ASTM B 160 – B 163

- ASTM B 725

- ASTM B 730

Nickel Alloy 200 Uses

Due to its excellent properties, nickel alloy 200 is used in various industrial applications. It is commonly used to manufacture chemical processing equipment, electronic components, aerospace components, and heat exchangers. Its high resistance to many corrosive environments makes it an ideal material for marine applications, where saline water and moist environments would otherwise damage other metals.

Nickel Alloy 200 Corrosion Resistance

Nickel alloy 200 is highly resistant to many corrosive agents, including dilute sulfuric acid, saltwater, and alkalis. It can withstand extreme environmental conditions, making it ideal for chemical processing equipment, electronics, and marine applications. Nickel alloy 200 is also resistant to stress corrosion cracking and offers good resistance to pitting and crevice corrosion.

Nickel Alloy 200 Heat Treatment

Nickel alloy 200 can be heat treated to increase hardness and strength. The most common heat treatment process for nickel alloy 200 is annealing, which softens the metal and reduces its hardness. This makes it easier to machine and form. However, nickel alloy 200 cannot be hardened by heat treatment.

Nickel Alloy 200 Machining

Nickel alloy 200 requires special machining techniques due to its high ductility and low work hardening rate. The recommended machining techniques for nickel alloy 200 include slow speed and heavy cuts, high feeds, and sharp cutting tools. The most commonly used cutting tools for nickel alloy 200 are carbide and high-speed steel—additionally, nickel alloy 200 machines are well under lubrication to reduce friction and heat accumulation.

Nickel Alloy 200 Welding

Nickel alloy 200 exhibits good welding properties and can be welded using various methods, including arc welding, TIG welding, and MIG welding. When welding nickel alloy 200, precautions are essential to prevent cracking, distortion, and porosity. The recommended welding techniques for nickel alloy 200 include preheating the metal, reducing the heat input, and controlling the welding speed.

![]()

![]()

![]()

![]()