-

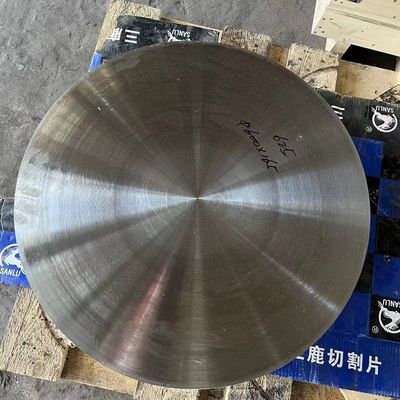

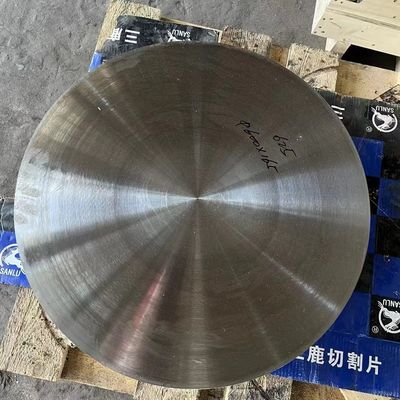

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

UNS S21800 Stainless Steel Round Bar Nitronic 60 Stainless Steel Alloy Rod

| Place of Origin | China |

|---|---|

| Brand Name | DELTA |

| Certification | ISO |

| Model Number | UNS S21800 / Nitronic 60 |

| Minimum Order Quantity | 500 kgs |

| Price | 10 - 12 USD/Kg |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 3 Ton per week |

| Products | Nickel Alloy Bars | Grade | UNS S21800 / Nitronic 60 |

|---|---|---|---|

| Diameter | 10- 350mm | Length | 6000mm Or Custom Cutting Any Length As Request |

| Standard | ASTM EN | Service | Cutting |

| Loading Port | Shanghai Port | Surface | Black, Bright |

| Highlight | Alloy Rod Stainless Steel Round Bar,UNS S21800 Stainless Steel Round Bar,Nitronic 60 Stainless Steel Round Bar |

||

UNS S21800 Stainless Steel Round Bar Nitronic 60 Stainless Steel Alloy Rod

| Form | Stainless Steel Round Bars |

| Grade | UNS S21800 / Nitronic 60 |

| Outer Diameter | 6mm-300mm or according to customer’s requirement |

| Length | custom cutting any length as request |

| Standard | ASTM, ASME, EN, JIS, DIN, GB/T, etc |

| Process Method | Hot Rolled, Cold Drawn, Cold Rolled, Forged Round Bar & Rod |

| Surface Finish | Bright, Hot Rolled Pickled, Cold Drawn, Sand Blasting Finished, Polished, Hairline |

| Other Grade |

Hastelloy : B2 B3 C22 C276 G30 X Stainless : 201 304 304L 309S 310S 316L 316Ti 317L 321 329 410 420 430 904L 2205 2507 904L 254SMO.etc |

| Price Item | EXW FOB CFR CIF |

| Payment | 30% TT inadvance, 70% TT Balance against copy of B/L |

| Delivery Time | It depends on your bars order total quantity and stock of these mother origin materials. Usually from the start of the order to the completion of production is about 3-4 weeks |

| Quality Requirement | Mill test certificate will be offered with shipment, the third party inspection is available |

| Main Markets | Europe, North America, Middle East, Southeast Asia |

| Metal Test | High or low temperature impact test, metallographic analysis |

| Chemical Analysis | As nickel alloy 718 bars standard |

Nitronic 60 Stainless Steel

Specifications:

Nitronic 60/UNS S21800

1. Alloy form: Bar, Sheet, Plate, Tube, Pipe, Wire, Cake, Ring, Flange

2. Provide free inspection and certificate

3. MOQ: 200kg

Product specific parameter standard

- S21800

- AMS 5848

- ASTM A193

- ASTM A194

- ASTM A240, ASTM A276

Nitronic 60

- Typical Mechanical Properties (Room Temperature)

s21800

| Nitronic 60 | ||||

| Condition | Ultimate Tensile ksi | Yield Strength (0.2%) ksi | Elongation % in 4D | % Reduction of Area |

|

s21800 Under 0.5" |

105 | 55 | 35 | 55 |

|

s21800 Over 0.5" |

95 | 50 | 35 | 55 |

Nitronic 60 stainless steel provides a significantly lower cost way to fight wear and galling compared with cobalt-bearing and high nickel alloys. Its uniform corrosion resistance is better than Type 304 in most media. Chloride pitting resistance is superior to Type 316. Room temperatrue yield strength is nearly twice that of Types 304 and 316. In addition, Nitronic 60 stainless steel provides excellent high-temperature oxidation resistance and low-temperature impact resistance.

Available Forms

Nitronic 60 stainless steel is available in bar, master alloy pigs, ingots and forging billets. Other forms available include sheet and strip, castings, extrusions, seamless tubing and plate.

Applications of Nitronic 60

Outstanding galling resistance at both ambient and elevated temperatures makes Nitronic 60 stainless steel a valuable material for valve sterns, seats and trim; fastening systems, including nuts and bolts; screening; chain-drive systems; pins, busings and roller bearings; and pump components such as wear rings and lobes. Nitronic 60 is the most effective wear and galling resistant alloy for bridge pins and other critical construction applications.

![]()

![]()

![]()

![]()

![]()

![]()