-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

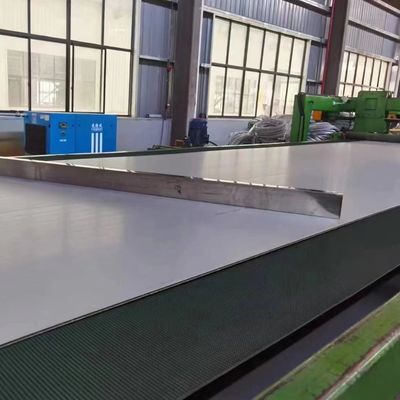

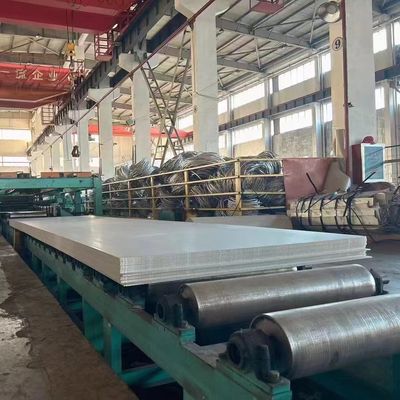

254SMO 00cr20ni18mo6cun 1.4547 Stainless Steel Sheet / Plate , 1.4547 Plate/EN 1.4547

| Products Name | Stainless Steel Checkered Plate | Grade | 254SMO |

|---|---|---|---|

| Thickness | 0.6-30.0mm | Standard | ASTM EN GB |

| Width | 1000mm 1219mm 1500mm | Surface | 2B NO.1 |

| Brand | TISCO BAOSTEEL | MOQ | 1 Ton |

| Highlight | 1.4547 Stainless Steel Sheet,EN 1.4547 Stainless Steel Sheet,254SMO Stainless Steel Sheet |

||

254SMO(00cr20ni18mo6cun)(1.4547) Stainless Steel Sheet / Plate , 1.4547 Plate/EN 1.4547

| Item | 254SMO Stainless Steel Plate |

| Raw Material | Stainless steel sheet (hot rolled and cold rolled) |

| Grades | 201, 202, 301, 304, 304L, 310S, 309S, 316, 316L, 321, 409L, 410, 410S, 420, 430, 904L, 2205 ,2507,254SMO,253MA.etc. |

| Thickness | 0.6 - 30.0mm |

| Stock Thickness | 0.6mm ,0.8mm,1.0mm,1.2mm,1.5mm.2mm, 2.5mm, 3mm, 3.5mm, 4mm, 4.5mm, 5mm, 5.5mm, 6mm, 7mm, 8mm,10.0mm,12.0mm,14.0mm,16.0mm,20.0mm,25mm,30.0mm |

| Width | 1000mm 1219mm 1500mm or cutting any size as your request |

| Finish | 2B, BA, No. 1, No. 4, mirror, brush, hairline, chequered, embossed, etc. |

| Package | Standard export package |

Surface finished of stainless steel

| Surface finish | Characteristics & Application |

| NO.1 |

Hot-rolled surface,annealed and pickled,can be used as cold-rolling material,industial tanks and chem i cal devices. |

| NO.2D |

Cold-rolled, an nealed and pick led with out skinpassing the dull prod ucts can be used as auto mo bile parts, build ing materrials and pipings. |

| NO.2B |

The surface brightness and flatness of NO.2B is better than NO.2D. Then through a special surface treament to improve its mechamical properties, N02B could nearly satisfy com pre hen sive uses. |

| NO.3 |

Polished with abra sive belt of grit #100#120,have bet ter bright ness with dis con tin u ous coarse stria, used as in ner and ex ter nal or na ments for building, elec tri cal ap pli anc es and kitchen uten sils etc. |

| NO.4 |

Polished with abrasive belt of grit #150-#180, have better brightness with discontinuous coarse stria, but thinner than NO.3, are used as bathtud building inner and external ornaments electrical appliances, kitchen utensils and food processing equipment etc. |

| #320 |

Polished with abrasive belt of grit #320, have better brightness with discontinuous coarse stria, but thinner NO.3, are used as bathtub building inner and external ornaments electrical appliances, kitchen utensils and food lprocessing equipment etc. |

| HL |

Polished with abrasive belt of grit #150-320 on the No.4 finish and has continuous streaks, mainly used as building ornaments, elevators, door of building, frontal plate etc. |

| BA |

Cold rolled, bright an nealed and skin-passed, the prod uct has ex cel lent bright ness and good re flex iv i ty like mirror, used for lectrical appliances, mirror, kitch en apparatus, or na ment ma te ri als etc. |

Our 254SMO Stainless Steel Products and Standard

| Form | ASTM |

| Rod, bar and shape | A 276, A 484 |

| Plate, sheet and strip | A 240, A 480 |

| Seamless and welded pipe | A 312, A 999 |

| Welded pipe | A 814, A 999 |

| Seamless and welded tubing | A 269, A 1016 |

| Fitting | A 403, A 960 |

| Forged or rolled pipe flange and forged fitting | A 182, A 961 |

| Forging | A 473, A 484 |

Chemical composition of 254SMO Stainless Steeel

| % | Fe | Cr | Ni | Mo | C | Mn | Si | P | S | Cu | N |

| min | balance | 19.5 | 17.5 | 6.0 | 0.50 | 0.18 | |||||

| max | 20.5 | 18.5 | 6.5 | 0.020 | 1.00 | 0.80 | 0.030 | 0.010 | 1.00 | 0.22 |

Physical properties of 254SMO Stainless Steel

| Density | 7.94 g/cm3 |

| Melting range | 1320-1390℃ |

Features: 254 SMO is a high performance austenitic stainless steel. Its high alloying

elements content imparts excellent resistance to uniform, pitting and crevice corrosion,

and stress corrosion cracking. It was originally developed to withstand the corrosion of acids,

especially in the presence of halide ions, such as hydrochloric acid, hydrofluoric acid,

phosphoric acid, and sulphuric acid contaminated with chlorides. In certain environments it is an alternative to more expensive nickel alloys and titanium alloys.

Applications: Chemical processing equipment, pulp and paper industry bleaching equipment, desalination plant seawater piping, food and beverage industry, pharmaceuticals,

and hydrometallurgy.

![]()

![]()

![]()

![]()