-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

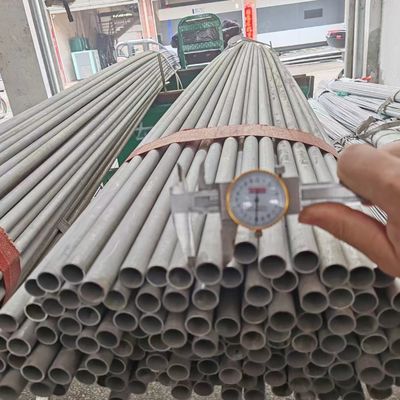

Bright Anneal / Hot Rolled 904L Stainless Steel Pipe DIN 1.4539 SS Pipe in 3m 6m Length

| Products | Stainless Steel Pipe | Grade | 904L |

|---|---|---|---|

| Standard | ASTM GB EN | Length | 6m Or Custom Cutting Any Length As Request |

| Diameter | DN10 - DN400 | Wall Thickness | SCH10 - XXS Or Unstandard Size |

| Type | Seamless Pipe | Service | Cutting, Polishing |

| Application | Industrial | Packing | Wooden Box Or PP Bag |

| Highlight | DIN 1.4539 Stainless Steel Pipe,904L Stainless Steel Pipe,Hot Rolled Stainless Steel Pipe |

||

Bright Anneal / Hot Rolled 904L Stainless Steel Pipe DIN 1.4539 SS Pipe in 3m 6m Length

| Product Name | Stainless Steel Pipe |

| Standard | JIS, AISI, ASTM, GB, DIN |

| Outer Diameter | 6mm-530mm (1/8"-20") or as the customers' requirements |

| Length | 1000-6000mm or as the customers' requirements |

| Grade | TP201, TP304, TP304L, TP310S, TP316, TP316L, TP317L, TP321, TP309S, TP410, TP420, TP430, TP904L |

| Thickness | 1mm-60mm |

| Type | weld |

| Surface | Pickled , Bright |

| manufacture | Hot Rolled/Cold Rolled |

| Application | Construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat ex-changer, machinery and hardware fields ,etc. |

| Packing | Weaving bag, non-woven fabric, seaworthy bundle,wooden case if required |

| Delivery time | Within 7 - 10 working days, according to customers' quantity |

| Payment | L/C or T/T |

| MOQ | 1 Ton |

| Quality | High Quality.SGS inspection is accepted if needed |

| Productivity | 1000 Tons/Month |

904L stainless steel is a superaustenitic stainless steel grade, Alloy 904L (UNS N08904) contains high levels of chromium and nickel with additions of molybdenum and copper to provide superior corrosion resistance.

The combination of high chromium and nickel content, coupled with additions of molybdenum and copper, assures good to excellent corrosion resistance, and moderate to high corrosion resistance in a wide range of process environments, containing dilute sulfuric acid. It also offers good resistance to other inorganic acids such as hot phosphoric acid as well as most organic acids.

Chemical Compositions

| Element | % Present (in product form) |

|---|---|

| Carbon (C) | 0.02 |

| Silicon (Si) | 0.70 |

| Manganese (Mn) | 2.00 |

| Phosphorous (P) | 0.03 |

| Sulfur (S) | 0.01 |

| Chromium (Cr) | 19.00 - 21.00 |

| Nickel (Ni) | 24.00 - 26.00 |

| Nitrogen (N) | 0.15 |

| Molybdenum (Mo) | 4.00 - 5.00 |

| Copper (Cu) | 1.20 - 2.00 |

| Iron (Fe) | Balance |

Mechanical properties (at room temperature in annealed condition)

| Product Form | ||||||||

|---|---|---|---|---|---|---|---|---|

| C | H | P | L | L | TW/TS | |||

| Thickness (mm) Max. | 8.0 | 13.5 | 75 | 160 | 2502) | 60 | ||

| Yield Strength | Rp0.2 N/mm2 | 2403) | 2203) | 2203) | 2304) | 2305) | 2306) | |

| Rp1.0 N/mm2 | 2703) | 2603) | 2603) | 2603) | 2603) | 2503) | ||

| Tensile Strength | Rm N/mm2 | 530 - 7303) | 530 - 7303) | 520 - 7203) | 530 - 7304) | 530 - 7305) | 520 - 7206) | |

| Elongation min. in % | Jmin (Longitudinal) | - | 100 | 100 | 100 | - | 120 | |

| Jmin (Transverse) | - | 60 | 60 | - | 60 | 90 | ||

Reference data on some physical properties

| Density at 20°C kg/m3 | 8.0 | |

|---|---|---|

| Thermal Conductivity W/m K at | 20°C | 12 |

| Modulus of Elasticity kN/mm2 at | 20°C | 195 |

| 200°C | 182 | |

| 400°C | 166 | |

| 500°C | 158 | |

| Specific Thermal Capacity at 20°C J/kg K | 450 | |

| Electrical Resistivity at 20°C Ω mm2/m | 1.0 | |

Processing / Welding

Standard welding processes for this steel grade are:

- TIG-Welding

- MAG-Welding Solid Wire

- Arc Welding (E)

- Laser Bean Welding

- Submerged Arc Welding (SAW)

Application of 904L Stainless Steel

Chemical plant, oil refinery, petrochemical plants, bleaching tanks for the paper industry, combustion gas desulfurisation plants, application in sea water, sulphuric and phosphoric acid. Due to the low C-content, the resistance to intergranular corrosion is also guaranteed in the welded condition.

![]()

![]()

![]()

![]()