-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

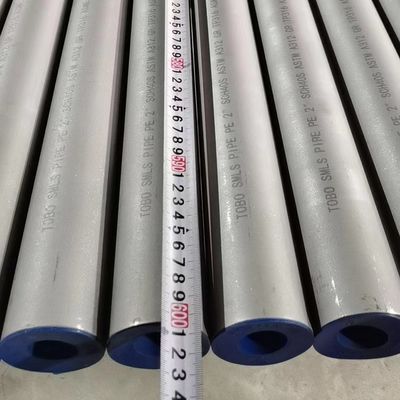

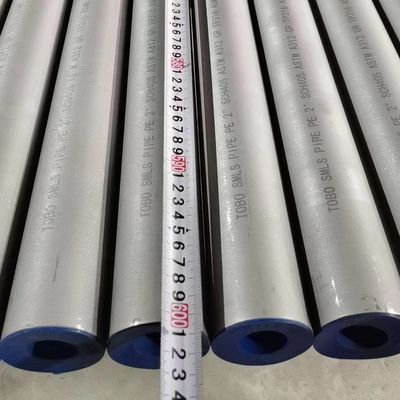

EN 10204-3.1 Certificated 316L Stainless Steel Pipe Tube SS Pipe Groove End Pipes

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Products | Stainless Steel Pipe | Grade | TP316L |

|---|---|---|---|

| Standard | ASTM GB EN | Length | 6m Or Custom Cutting Any Length As Request |

| Diameter | DN10 - DN400 | Wall Thickness | SCH10 - XXS Or Unstandard Size |

| Type | Seamless Pipe | Service | Cutting, Polishing |

| Application | Industrial | Packing | Wooden Box Or PP Bag |

| Highlight | 316L Stainless Steel Pipe,EN 10204-3.1 Stainless Steel Pipe,SS Pipe Groove End Pipes |

||

EN 10204-3.1 Certificated 316L Stainless Steel Pipe Tube SS Pipe Groove End Pipes

| Product Name | Stainless Steel Pipe |

| Standard | JIS, AISI, ASTM, GB, DIN |

| Outer Diameter | 6mm-530mm (1/8"-20") or as the customers' requirements |

| Length | 1000-6000mm or as the customers' requirements |

| Grade | TP201, TP304, TP304L, TP310S, TP316, TP316L, TP317L, TP321, TP309S, TP410, TP420, TP430, TP904L |

| Thickness | 1mm-60mm |

| Type | weld |

| Surface | NO.1/NO.4/8K/HL/BA/2B |

| manufacture | Hot Rolled/Cold Rolled |

| Application | Construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat ex-changer, machinery and hardware fields ,etc. |

| Packing | Weaving bag, non-woven fabric, seaworthy bundle,wooden case if required |

| Delivery time | Within 7 - 10 working days, according to customers' quantity |

| Payment | L/C or T/T |

| MOQ | 1 Ton |

| Quality | High Quality.SGS inspection is accepted if needed |

| Productivity | 1000 Tons/Month |

About Grade 316L Tubes

Grade 316L is basically an improved version of grade 316. In general, it is standard molybdenum grade among the austenitic steels. The molybdenum present in the 316L gives a better overall corrosion resistance property compared to other grades. The higher resistance is toward the crevice corrosion, pitting corrosion in an environment involving chloride.

grade 316L is also known as the low carbon version of its prior version that has high immunity toward sensitization i.e. grain boundary carbide precipitations. They got extensively used in gas and oil as well as chemical industries because of its cost-effective resistance toward corrosion and fabrication ease. There isn’t any appreciable price between the 316L and 316 stainless steel. The structure gives excellent toughness in cryogenic temperatures. In comparison to chromium-nickel stainless steel, it offers a high creep, tensile strength, stress to rupture at elevated temperature. These alloy got considered for its wide variety of usage where more or just one property is required. They are available in straight, seamless, cold redrawn and seam welded. Typical applications in which it got utilized are semiconductors, condensers, process engineering, and control lines. The mechanical properties like tensile, elongation, etc and physical properties like specific heat, thermal expansion, thermal conductivity, electrical resistivity, and density are mixed in such a way that makes it a better tube.

ASME SA213 316L Stainless Steel Tubes Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 316L | 1.4404 / 1.4435 | S31603 | SUS 316L | 316S11 / 316S13 | 03Ch17N14M3/ 03Ch17N14M2 | Z3CND17?11?02 / Z3CND18?14?03 | X2CrNiMo17-12-2 / X2CrNiMo18-14-3 |

Stock Size Range and Specifications For Stainless Steel 316L Tube

- Tube Specification : ASTM A213, A269, A249, A511, A554 / ASME SA213, SA269, SA249, SA511, SA554

- Dimension Standard : ANSI B36.19, ANSI B36.10

- Outside Diameter : 1/8" OD TO 2"OD 3MM OD TO 38 MM OD

- Thickness Range : 1MM TO 3 MM 0.028 TO 0.156 IN, SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS

- Type : Seamless / ERW / Welded / Capillary Tubes

- Form : Round Tube, Square Tube, Rectangular Tube

- Length : Single Random, Double Random & Required Length

- End : Plain End, Beveled End, Treaded

- End Protection : Plastic Caps

- Finish : Annealed and Pickled, Polished, Bright Annealed, Cold Drawn

- External Coating : 3LPE / 3LPP/ FBE/ DFBE/ PP

- Specials : Sizes and Specifications other than above can be manufactured on request

Chemical Composition of Stainless Steel 316L Tubing

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Fe |

| SS 316L | 0.035 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 16.00 - 18.00 | 2.00 - 3.00 | 11.00 - 14.00 | 68.89 min |

Mechanical Properties of SS 316L / S31603 / 1.4404 / SUS 316L Tubes

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1399 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

Stainless Steel 316L Tubes Application Industries

- Petrochemical Industry

- Chemical Industry

- Oil and Gas Industry

- Pulp & Paper Indusry

- Power Plant Industry

- Food Processing Industry

- Pharmaceuticals Industry

- Energy Industry

- Aerospace Industry

![]()

![]()

![]()

![]()