All Products

-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

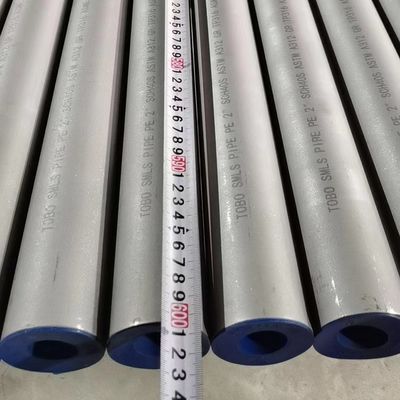

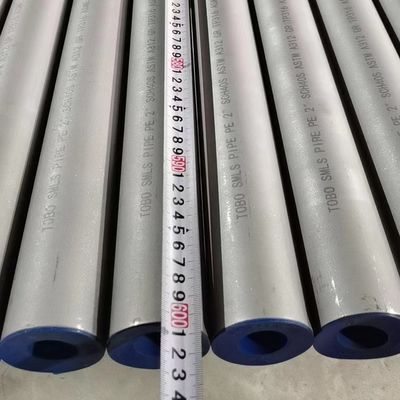

Pickling SS Pipe / Bright Polished Stainless Steel Pipe / TP316L 1.4404 316L Stainless Tube

Product Details

| Products | Stainless Steel Pipe | Grade | TP316L |

|---|---|---|---|

| Standard | ASTM GB EN | Length | 6m Or Custom Cutting Any Length As Request |

| Diameter | DN10 - DN400 | Wall Thickness | SCH10 - XXS Or Unstandard Size |

| Type | Seamless Pipe | Service | Cutting, Polishing |

| Application | Industrial | Packing | Wooden Box Or PP Bag |

| Highlight | Bright Polished Stainless Steel Pipe,TP316L Stainless Steel Pipe,Pickling Stainless Steel Pipe |

||

Product Description

Pickling SS Pipe / Bright Polished Stainless Steel Pipe / TP316L 1.4404 316L Stainless Tube

| TP316L Bright Annealed Tubing, 1/2inch Stainless Steel Tube | ||||||||||

| Outside Diameter | 3.2-25.4mm | |||||||||

| Wall Thickness | 0.2-2.5mm | |||||||||

| Length | As customer's requirement; In coil or in straight. | |||||||||

| Standard | ASTM A213/ ASME SA213, ASTM A269/ASME SA269, EN10216-5, etc. | |||||||||

| Grade | TP304, TP304L, TP316, TP316L, TP321, TP247H, etc. | |||||||||

| Delivery Condition | Pickled, Polished, Bright Annealed | |||||||||

| Technique | Seamless/Welded | |||||||||

| Application | Automotive industry, Aircraft/Aerospace, Instrumentation & Electrical, Chemical Industry, etc. | |||||||||

| Marking | LOGO, Standard, Grade, Size, Heat Number. | |||||||||

| Package | Woven bag, wooden cases, or as per customer's requirement. | |||||||||

| Quality Requirement | Mill Test Certificate (EN 10204/3.1); Third Part Inspection is acceptable. | |||||||||

Standard SIze of our 316L Stainless Steel Pipe

| Normal Size | |||||

| OD 3/16” | WT0.02” | 4.76x0.51mm | OD3/16” | WT0.028” | 4.76x0.71mm |

| OD3/16” | WT0.035” | 4.76x0.89mm | OD3/16” | WT0.049” | 4.76x1.24mm |

| OD0.24” | WT0.04” | 6x1mm | OD0.24” | WT0.06” | 6x1.5mm |

| OD1/4” | WT0.02” | 6.35x0.51mm | OD1/4” | WT0.028” | 6.35x0.71mm |

| OD1/4” | WT0.035” | 6.35x0.89mm | OD1/4” | WT0.049” | 6.35x1.24mm |

| OD1/4” | WT0.065” | 6.35x1.65mm | OD5/16” | WT0.028” | 7.94x0.71mm |

| OD5/16” | WT0.035” | 7.94x0.89mm | OD5/16” | WT0.049” | 7.94x1.24mm |

| OD5/16” | WT0.065” | 7.94x1.65mm | OD3/8” | WT0.028” | 9.53x0.71mm |

| OD3/8” | WT0.035” | 9.53x0.89mm | OD3/8” | WT0.049” | 9.53x1.24mm |

| OD3/8” | WT0.065” | 9.53x1.65mm | OD0.4” | WT0.04” | 10x1mm |

| OD0.4” | WT0.06” | 10x1.5mm | OD0.4” | WT0.079” | 10x2mm |

| OD0.47” | WT0.065” | 12x1mm | OD0.47” | WT0.06” | 12x1.5mm |

| OD1/2” | WT0.028” | 12.7x0.71mm | OD1/2” | WT0.035” | 12.7x0.89mm |

| OD1/2” | WT0.049” | 12.7x1.24mm | OD1/2” | WT0.065” | 12.7x1.65mm |

| OD0.55” | WT0.04” | 14x1mm | OD0.55” | WT0.06” | 14x1.5mm |

| OD5/8” | WT0.028” | 15.88x0.71mm | OD5/8” | WT0.035” | 15.88x0.89mm |

| OD5/8” | WT0.049” | 15.88x1.24mm | OD5/8” | WT0.065” | 15.88x1.65mm |

| OD5/8” | WT0.083” | 15.88x2.11mm | OD0.63” | WT0.065” | 16x1mm |

| OD0.63” | WT0.06” | 16x1.5mm | OD0.63” | WT0.079” | 16x2mm |

| OD3/4” | WT0.04” | 19.05x1mm | OD3/4” | WT0.049” | 19.05x1.24mm |

| OD3/4” | WT0.065” | 19.05x1.65mm | OD3/4” | WT0.083” | 19.05x2.11mm |

| OD1” | WT0.049” | 25.4x1.24mm | OD1” | WT0.0665” | 25.4x1.65mm |

| OD1” | WT0.083” | 25.4x2.11mm | OD1” | WT0.1” | 25.4x2.54mm |

Application:

-

Instrument Tubing

-

Chromatography tubing

-

Hydraulic Tubing

-

High Pressure Tubing

-

Cleaned Tubing

-

Multi Core Tubing

-

Heat Exchanger

-

Etc.

Inspection:

![]()

![]()

![]()

![]()

-

PMI Test

-

Hydraulic Test

-

Eddy Current Test

-

Non-Destructive Test

-

Etc.

Recommended Products