-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

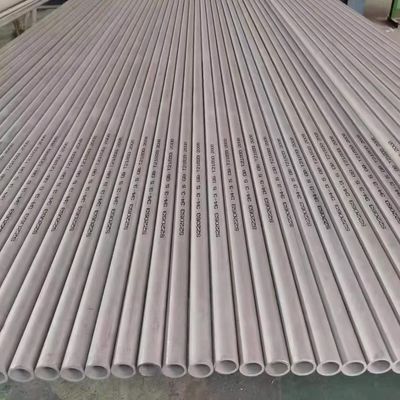

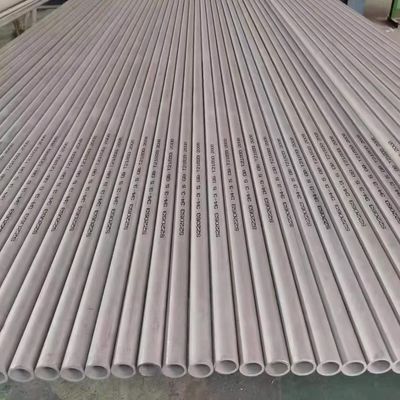

EN 10204-3.1 Certificated 904L 1.4539 UNS N08904 Alloy 904L Stainless Steel Pipe Tube

| Place of Origin | China |

|---|---|

| Brand Name | DELTA |

| Certification | ISO |

| Model Number | 904L / 1.4539 |

| Minimum Order Quantity | 500 kgs |

| Price | 4650-5760 USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | T/T, Western Union, L/C |

| Supply Ability | 10 Ton per week |

| Products | Stainless Steel Pipe | Grade | 904L |

|---|---|---|---|

| Standard | ASTM GB EN | Length | 6m Or Custom Cutting Any Length As Request |

| Diameter | DN10 - DN400 | Wall Thickness | SCH10 - XXS Or Unstandard Size |

| Type | Seamless Pipe | Service | Cutting, Polishing |

| Application | Industrial | Packing | Wooden Box Or PP Bag |

| Highlight | 1.4539 Stainless Steel Pipe,UNS N08904 Stainless Steel Pipe,EN 10204-3.1 Stainless Steel Pipe |

||

EN 10204-3.1 Certificated 904L 1.4539 UNS N08904 Alloy 904L Stainless Steel Pipe Tube

| Material | Alloy 904L 1.4539 N08904 X1NiCrMoCu25-20-5 |

| Alloy 904l Tubing Standards | ASTM B/ASME SB674 / SB677, ASTM A312/ ASME SA312 |

| Standard Specification for UNS N08904 Tubes | ASTM B677 UNS N08904, ASTM B673 UNS N08904, ASTM B674 UNS N08904 |

| Seamless Tube Size | 3.35 mm OD To 101.6 mm OD |

| Welded Tube Size | 6.35 mm OD To 152 mm OD |

| Swg & Bwg | 10 Swg., 12 Swg., 14 Swg., 16 Swg., 18 Swg., 20 Swg. |

| Schedule | SCH5, SCH10, SCH10S, SCH20, SCH30, SCH40, SCH40S, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

| AISI 904l Tube wall thickness | 0.020″ –0.220″, (special wall thicknesses available) |

| Manufacturing Specifications | ASTM A312

ASTM A213 ASTM A269 BS EN 10216 pt.5 As per customer’s specifications. |

| Length | Single Random, Double Random, Standard & Cut length |

| Finish | Polished, AP (Annealed & Pickled), BA (Bright & Annealed), MF |

| 904L Steel Pipe Form | Straight, Coiled, Square Pipes/ Tubes, Rectangular Pipe/ Tubes, Coiled Tubes, Round Pipes/ Tubes, “U” Shape for heat exchangers, Hydraulic Tubes, Pan Cake Coils, Straight or ‘U’ bent Tubes, Hollow, LSAW Tubes Etc. |

| 904l Stainless Tube Type | Seamless, ERW, EFW, Welded, Fabricated |

| End | Plain End, Beveled End, Treaded |

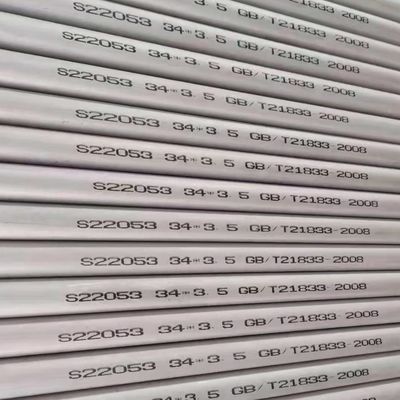

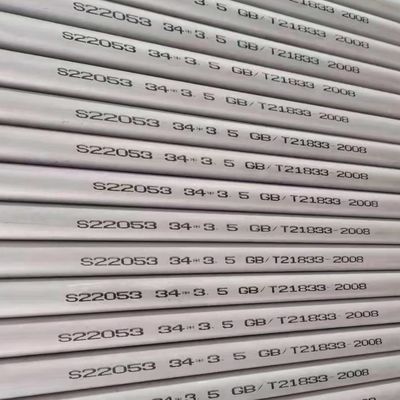

| Marking | All Stainless Steel 904L tubes are marked as follows: Standard, Grade, OD, Thickness, Length, Heat No. (Or according to the customer’s request.) |

| Application | Oil Tube, Gas Tube, Fluid Tube, Boiler and Heatexchanger |

| Value Added Service | Draw & Expansion as per required Size & Length, Polish (Electro & Commercial) Annealed & Pickled Bending, Machining Etc. |

| Specialize in | 904L Stainless Steel Capillary Tube & Other Odd Size 904L Stainless Steel Heat Exchanger & Condenser Tubes |

| Top 10 Manufacturer of 904L Tubes | Posco Korea, VDM Germany, Tubacex, Nippon Steel Corporation, Sumitomo Japan, Indian Mills, Walsin, SP Metal, RONSCO, BAOSTEEL, JISCO, TISCO |

| Test Certificate | Manufacturer Test Certificate Laboratory Test Certificate from Govt. Approved Lab. Under Third Party Inspection |

904L Stainless Steel Seamless Tubes Surface Finish

| Surface Finish | Internal Surface(ID) | Exterbal Surface(OD) | |||

| Roughness Average(RA) | Roughness Average(RA) | ||||

| μ inch | μm | μ inch | μm | ||

| AP | Annealed & Pickled | Not defined | Not defined | 40 or Not defined | 1.0 or Not defined |

| BA | Beight Annealed | 40,32,25,20 | 1.0,0.8,0.6,0.5 | 32 | 0.8 |

| MP | Mechanical Polish | 40,32,25,20 | 1.0,0.8,0.6,0.5 | 32 | 0.8 |

| EP | Electro Polish | 15,10,7,5 | 0.38,0.25,0.20;0.13 | 32 | 0.8 |

What is 904L Stainless Steel?

904L stainless steel is a high-alloy austenitic stainless steel that contains molybdenum, copper, and low carbon content. The low carbon content makes 904L stainless steel less susceptible to sensitization and intergranular corrosion, making it ideal for harsh environments. The high nickel and chromium content resists chloride stress-corrosion cracking and pitting corrosion.

Advantages of 904L Stainless Steel Pipe

904L stainless steel pipe has numerous advantages over other steel pipes, including corrosion resistance, superior durability and a high strength-to-weight ratio. 904L is more resistant than traditional stainless steels to various forms of acid attack and stress corrosion cracking due to its elevated levels of chromium, nickel, molybdenum and copper – which can all be found in the alloy composition. It also boasts improved physical properties, such as increased tensile strength under specific conditions. Being used for medical applications with strict hygiene requirements, 904L pipes offer much greater resistance against potential contamination from external agents. Furthermore, it can be welded with conventional methods despite its relatively high alloy content. All these features make it an ideal choice for piping infrastructure across numerous sectors, including medical, automotive and even food processing industries.

Corrosion Resistance

904L stainless steel pipe provides exceptional corrosion resistance due to its low carbon, high nickel and molybdenum content. Its chemical composition offers higher resistance to severely corrosive environments such as chlorides, sea water and sulfuric acid compared to other grades of stainless steel. It is ideal for industries that require superior corrosion-resistant properties, such as chemical processing plants, oil & gas production facilities and pulp & paper mills. The additional chromium in 904L also gives it better welding properties than traditional austenitic stainless steel pipes.

Low-Maintenance

904L stainless steel pipe offers a low-maintenance solution for many industrial and commercial applications. It is highly corrosion-resistant and ideal for environments exposed to atmospheric conditions or extreme temperatures. Furthermore, its high chromium content results in increased durability and strength. In addition, 904L stainless steel pipe requires minimal cleaning and maintenance due to its non-porous surface, which prevents dirt or particles from sticking and building upon the material. Finally, this material can be welded easily with other metals while preserving its properties.

Temperature Range

904L stainless steel pipe has a distinct temperature range that allows it to be used in many applications. It can handle temperatures up to 600°F and even withstand greater temperatures for short periods. These high-temperature capabilities make 904L stainless steel pipes ideal for various industrial, medical, marine, and chemical uses. Its superior corrosion resistance over conventional SS304 makes it ideal for the most demanding applications, while its low cost helps keep costs down. It’s also magnetic, so it’s easy to work with and shape as desired. All these beneficial properties make 904L stainless steel an excellent choice for any project!

High-Strength

904L stainless steel pipes have high tensile strength and withstand high pressure and temperature.

Versatility

Due to their corrosion-resistant properties, 904L stainless steel pipes are used in various industries, including chemical and petrochemical plants, food processing, oil and gas, and pharmaceuticals.

Applications of 904L Stainless Steel Pipe

The properties of 904L stainless steel make it suitable for various applications. The most common applications include:

Chemical and Petrochemical Plants

904L stainless steel pipes are widely used in chemical and petrochemical plants exposed to high concentrations of corrosive fluids.

Food Processing

904L stainless steel pipes are used in food processing applications because of their hygienic properties and resistance to acids and alkaline solutions.

Oil and Gas Industry

904L stainless steel pipes are commonly used in the oil and gas industry due to their ability to withstand extreme temperatures and high-pressure conditions.

![]()

![]()

![]()

![]()