-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

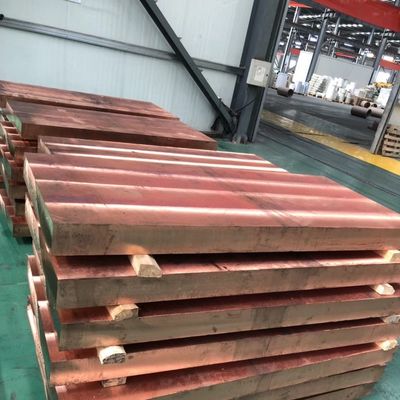

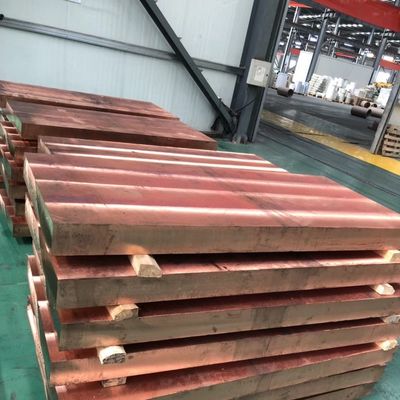

ASTM Standard C10200 Copper Oxygen Free High Conductivity C10200 Plate & Sheet

| Products | Copper Flta Bar | Grade | C10200 |

|---|---|---|---|

| Standard | ASTM GB EN DIN JIS | Thickness | 0.5 - 60.0mm |

| Width | Within 1000mm | Length | 6m Or Custom As Request |

| Certificate | EN 10204-3.1 | Other Products | Pipe , Round Bar, Strips |

| Highlight | High Conductivity Copper Plate & Sheet,ASTM Standard Copper Plate & Sheet,Oxygen Free Copper Plate & Sheet |

||

ASTM Standard C10200 Copper, Oxygen Free High Conductivity C10200 Plate & Sheet

|

Product name

|

Copper Plate & Sheet |

| Copper and copper alloy grade |

C11000,C10100,C12200

H59, H60, H62, H65, H68, H70, H80, H85, H90, H96, C2100, C2200,C2300, C2400, C2600, C2680, C2720, C2800, C3560, C3601, C3713, C3771, C3561 , CuZn30, CuZn32, CuZn35, CuZn37, CuZn40 ,TU1, T2, TP2, H96, H90, H85, H80, H70, H65, H63, H62, H59, HPb63-3, HPb66-0.5, HPb62-2, HPb62-3, HPb59-3, HSn70-1, HSn62-1,QSn8-0.3, QSn4-4-4, QAl9-4, QSB-1 etc.

|

| Width | Within 1500mm Custom Cutting any width as request |

| Thickness | 0.5 - 200.0mm |

|

Length |

1m 2m 3m 6m or custom cutting any length as request |

| Standard | ASTM EN DIN JIS GB |

| Other products | Plate, Sheet, Coil , Pipe, Round Bar, Square Bar, Flat Bar, Hexagonal Bar.etc |

Oxygen-free copper—also referred to as OFC, Cu-OF, Cu-OFE, and oxygen-free, high-conductivity copper (OFHC)—is formed by melting copper and combining it with carbon and carbonaceous gases. The electrolytic copper refining process removes most of the oxygen contained within, resulting in a compound that consists of 99.95–99.99% copper with less than or equal to 0.0005% oxygen.

The high purity levels of oxygen-free copper enhance the properties typical of standard copper material, such as thermal and electrical conductivity, ductility, impact strength, and machinability. Due to these advantageous properties, the material finds use in a variety of industrial applications.

Oxygen-Free Copper: Grades, Forms, Compositions, and Properties

Oxygen-free copper materials are classified by the amount of oxygen removed from the base copper material. The two basic grades are:

- Cu-OF (C10200) grade copper is oxygen-free up to 99.95%. This grade of copper boasts exceptional purity. While no copper is ever 100% pure, modern technology has allowed refiners to reduce the remaining oxygen content to a practical range of 0.001–0.003%.

- Cu-OFE (C10100) grade copper is oxygen-free up to 99.99%. It is purer than Cu-OF and exhibits a slightly higher percentage of electrical conductivity (approximately 1%) and superior corrosion resistance. Additionally, it is often used for high-quality audio/visual systems.

Both grades of oxygen-free copper are available in a wide variety of forms and shapes, including:

- Plate

- Rod

- Sheet

- Strip

- Tube

Although Cu-OF and Cu-OFE have slightly different compositions due to the .04% variance in residual oxygen level, they share many characteristics. For instance, they both contain the following properties in soft to hard conditions:

- Tensile strength of 222–385 N/mm2

- Proof strength range (to 0.1% deformation) of 60–325 N/mm2

- Elongation of 60-4%

- Hardness range of 45–115 HV

- Average conductivity of 102% and a guaranteed value of 101% as per IACS

- Thermal conductivity ranges between 386–394 W/m°C

Oxygen-Free Copper (OFC) Production

Oxygen-free copper (OFC) is formed via an intensive manufacturing and refining process that includes melting the copper and incorporating gases into the final composition. To prevent distortion and the formation of cracks within the material, manufacturers can add heat treatments to the production process to relieve stress. If the OFC is not softened during the heat treating process, then the manufacturer needs to perform further annealing (tempering) operations on the material to strengthen it.

Applications of Oxygen-Free Copper (OFC)

Oxygen-free copper is highly suitable for a number of industrial applications, including the manufacture of electronic products and products that operate within vacuum conditions. Some of the electronic products for which OFC is used are:

- Anodes

- Bus conductors

- Busbars

- Coaxial cables

- Glass-to-metal seals

- Hollow conductors

- Klystrons

- Lead-in wires

- Medical devices

- Rectifiers

- Transistor components

- Tubes

- Vacuum seals & vacuum applications

- Waveguides

![]()

![]()

![]()

![]()