All Products

-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

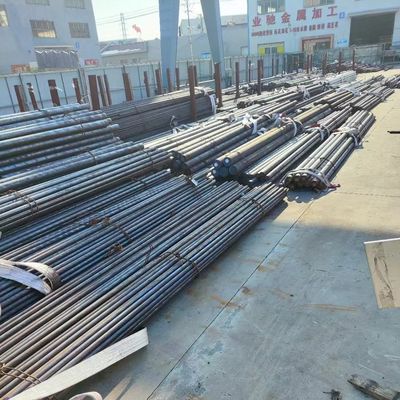

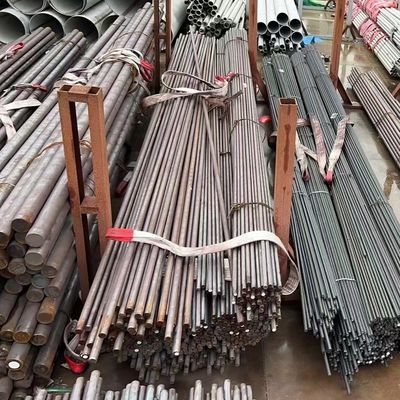

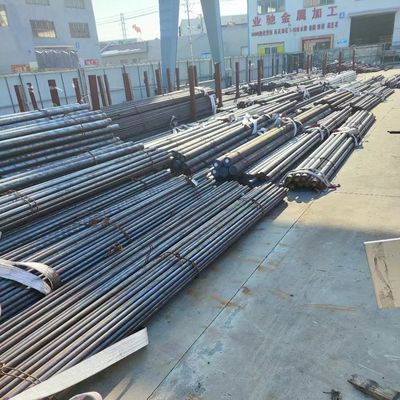

Incoloy 925 Nickel Alloy Base Round Bar Alloy 925 Bars Black Bars

Product Details

| Products | Nickel Alloy Bars | Grade | Incoloy 925 |

|---|---|---|---|

| Diameter | 6 - 250mm | Length | 6000mm Or Custom Cutting Any Length As Request |

| Standard | ASTM EN | Service | Cutting |

| Loading Port | Shanghai Port | Surface | Black, Bright |

| Highlight | Black Bars Nickel Alloy,Incoloy 925 Nickel Alloy,Alloy 925 Bars Black |

||

Product Description

Incoloy 925 Nickel Alloy Base Round Bar Alloy 925 Bars Black Bars

| Form | Nickel Alloy Bars |

| Grade | incoloy 925 |

| Outer Diameter | 6mm-250mm or according to customer’s requirement |

| Length | 1meter, 3 meters and 6 meters or customer’s requirement |

| Standard | ASTM, ASME, EN, JIS, DIN, GB/T, etc |

| Process Method | Hot Rolled, Cold Drawn, Cold Rolled, Forged Round Bar & Rod |

| Surface Finish | Bright, Hot Rolled Pickled, Cold Drawn, Sand Blasting Finished, Polished, Hairline |

| Other Grade |

Hastelloy : B2 B3 C22 C276 G30 X Incoloy: 800 800H 800HT 825 925 A286 330 Inconel: 600 601 617 625 718 725 X-750 Monel: 400 k-500 |

| Price Item | EXW FOB CFR CIF |

| Payment | 30% TT inadvance, 70% TT Balance against copy of B/L |

| Delivery Time | It depends on your bars order total quantity and stock of these mother origin materials. Usually from the start of the order to the completion of production is about 3-4 weeks |

| Quality Requirement | Mill test certificate will be offered with shipment, the third party inspection is available |

| Main Markets | Europe, North America, Middle East, Southeast Asia |

| Metal Test | High or low temperature impact test, metallographic analysis |

| Chemical Analysis | As nickel alloy 925 bars standard |

Standard Size of Alloy 925 Round Bar in Stock

| 4mm | 5mm | 6mm | 8mm | 10mm | 12mm | 14mm | 15mm |

| 16mm | 18mm | 19mm | 20mm | 21mm | 22mm | 24mm | 25mm |

| 27mm | 28mm | 30mm | 32mm | 34mm | 35mm | 38mm | 40mm |

| 42mm | 45mm | 48mm | 50mm | 55mm | 60mm | 65mm | 70mm |

| 75mm | 80mm | 85mm | 90mm | 95mm | 100mm | 105mm | 110mm |

| 115mm | 120mm | 125mm | 130mm | 135mm | 140mm | 150mm | 155mm |

| 160mm | 170mm | 180mm | 190mm | 200mm | 205mm | 210mm | 220mm |

| 230mm | 240mm | 250mm | 260mm | 270mm | 280mm | 290mm | 300mm |

925 is a superalloy of Nickel with a high-value Chromium and Iron combination to get Enhanced level strength. It is implemented with the addition of Molybdenum Copper and Titanium that amplify the corrosion resistance properties of alloy with age hardening benefit. As a result, it is more demanded superior strength and in major corrosive applications. It shows unique resistance properties against corrosion. Therefore it handles several chemical processes and surroundings, avoiding specific reducing effects.

Incoloy 925 Round Bar Specification

- Specifications : ASTM B805 / ASME SB805

- Dimensions : EN, DIN, JIS, ASTM, BS, ASME, AISI, ASTM, ASME

- Size : 5 mm To 500 mm

- Length : 6 meter

- Form : Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forging Etc.

- Finish : Cold drawn, Bright drawn, Centreless ground, Cold finished, Peeled and turned, Smooth turned, Slit rolled edge, Hot finished, Hot rolled, Rough turned/peeled, Peeled and reeled

- Tolerance : H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirements

CHEMICAL COMPOSITION OF INCOLOY 925 ROUND BAR

| Grade | C | Mo | Si | S | Cu | Fe | Ni | Cr | Al | Ti |

| Incoloy 925 | 0.01 max | 3 max | 0.5 max | 0.03 max | 1.8 | 28 | 44 | 21 | 0.3 | 2.1 |

MECHANICAL COMPOSITION OF INCOLOY 925 ROUND BAR

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.05 g/cm³ | 1343 °C (2450 °F) | Psi – 175000 , MPa – 1210 | Psi – 117000 , MPa – 810 | 24 % |

Applications utilizing these INCOLOY 925 ROUND BAR are:

- Sour gas equipments

- Seawater Components

- Acid Process

- Piping Systems

![]()

![]()

![]()

![]()

Recommended Products