-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

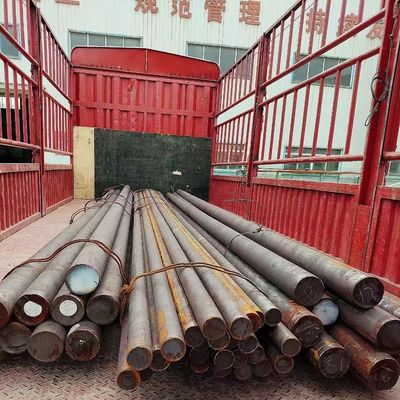

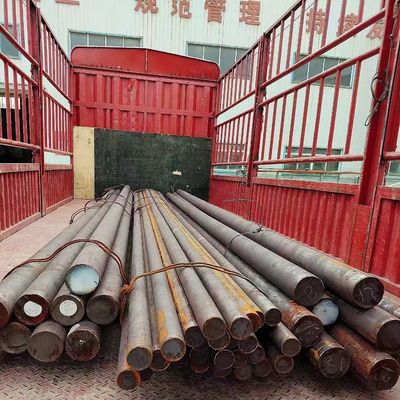

UNS N10675 / Hastelloy B-3 Round Bar / Rod with EN 10204-3.1 Certificate

| Products | Nickel Alloy Bars | Grade | Hastelloy B-3 |

|---|---|---|---|

| Diameter | 6 - 250mm | Length | 6000mm Or Custom Cutting Any Length As Request |

| Standard | ASTM EN | Service | Cutting |

| Loading Port | Shanghai Port | Surface | Black, Bright |

| Highlight | UNS N10675 Round Bar,N10675 Round Bar |

||

UNS N10675 / Hastelloy B-3 Round Bar / Rod with EN 10204-3.1 Certificate

| Form | Nickel Alloy Bars |

| Grade | Alloy B-2 |

| Outer Diameter | 6mm-250mm or according to customer’s requirement |

| Length | 1meter, 3 meters and 6 meters or customer’s requirement |

| Standard | ASTM, ASME, EN, JIS, DIN, GB/T, etc |

| Process Method | Hot Rolled, Cold Drawn, Cold Rolled, Forged Round Bar & Rod |

| Surface Finish | Bright, Hot Rolled Pickled, Cold Drawn, Sand Blasting Finished, Polished, Hairline |

| Other Grade |

Hastelloy : B2 B3 C22 C276 G30 X Incoloy: 800 800H 800HT 825 925 A286 330 Inconel: 600 601 617 625 718 725 X-750 Monel: 400 k-500 |

| Price Item | EXW FOB CFR CIF |

| Payment | 30% TT inadvance, 70% TT Balance against copy of B/L |

| Delivery Time | It depends on your bars order total quantity and stock of these mother origin materials. Usually from the start of the order to the completion of production is about 3-4 weeks |

| Quality Requirement | Mill test certificate will be offered with shipment, the third party inspection is available |

| Main Markets | Europe, North America, Middle East, Southeast Asia |

| Metal Test | High or low temperature impact test, metallographic analysis |

| Chemical Analysis | As nickel alloy B-3 bars standard |

Standard Size of Hastelloy B-3 Round Bar in Stock

| 4mm | 5mm | 6mm | 8mm | 10mm | 12mm | 14mm | 15mm |

| 16mm | 18mm | 19mm | 20mm | 21mm | 22mm | 24mm | 25mm |

| 27mm | 28mm | 30mm | 32mm | 34mm | 35mm | 38mm | 40mm |

| 42mm | 45mm | 48mm | 50mm | 55mm | 60mm | 65mm | 70mm |

| 75mm | 80mm | 85mm | 90mm | 95mm | 100mm | 105mm | 110mm |

| 115mm | 120mm | 125mm | 130mm | 135mm | 140mm | 150mm | 155mm |

| 160mm | 170mm | 180mm | 190mm | 200mm | 205mm | 210mm | 220mm |

| 230mm | 240mm | 250mm | 260mm | 270mm | 280mm | 290mm | 300mm |

Overview of Hastelloy B-3 Alloy

Hastelloy B-3 alloy (UNS N10675/W.Nr. 2.4600) exhibits extremely high resistance to pure hydrochloric, hydrobromic, and sulfuric acids.

Furthermore, it has greatly improved structural stability compared with previous B-type alloys, leading to fewer concerns during welding, fabrication, and service.

Like other nickel alloys (in the mill annealed condition), it is ductile, can be formed and welded, and resists stress corrosion cracking in chloride-bearing solutions. Also, it is able to withstand fluoride-bearing media and concentrated sulfuric acid, both of which result in damage to zirconium alloys. It is used in numerous chemical process industry (CPI) applications, especially in the construction of reaction vessels for pure, reducing acid service.

The molybdenum content of the nickel-molybdenum (B-type) alloys is such that there is a strong tendency for phases other than the desirable (face-centered cubic) gamma phase to form in the microstructure, particularly in the temperature range 500°C to 900°C. The most deleterious of these alternate phases is Ni4Mo, which forms quickly at certain temperatures, affects ductility, and reduces resistance to stress corrosion cracking.

The chief attribute of Hastelloy B-3 alloy, as compared with other modern B-type materials, is its greatly improved structural stability.

| Grade | Standard | C | Si | Mn | Mo | Co | Cr | Ni | Ti |

| Hastelloy B-3 | AMS 5542 | ≤0.01 | ≤0.10 | ≤3.00 | 27.0-32.0 | ≤3.0 | 1.0-3.0 | ≥65 | ≤0.20 |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 9.22 g/cm3 | 1418°C (2585°F) | 860Mpa | 420Mpa | 50% |

Features of Hastelloy B-3

1. It has strong corrosion resistance in acidic media such as hydrochloric acid, sulfuric acid, and formic acid

2. Strong thermal stability and structural stability

3. It has higher ductility than Hastelloy B-2, and can be welded and integrally formed

4. Long embrittlement time at high temperature

5. Excellent resistance to pitting, corrosion and stress corrosion cracking

Hastelloy B-3 Alloy Applications

Hastelloy B-3 alloy can be used in a variety of applications including:

- The production and processing of many concentrated acids

- Mechanical components and vacuum furnaces

- Chemical processing

![]()

![]()

![]()

![]()