All Products

-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

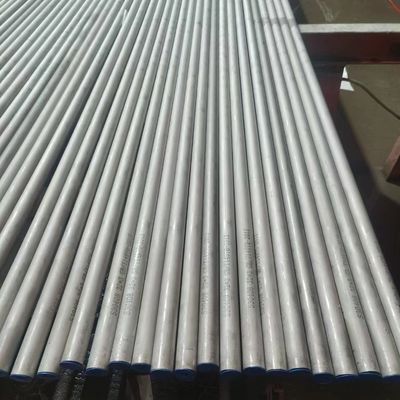

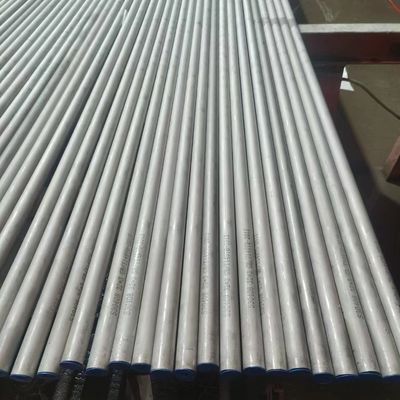

Inconel 625 / UNS N06625 Nickel Alloy Seamless Steel Pipe Tube SS Tube Cutting and Polishing

| Place of Origin | China |

|---|---|

| Brand Name | DELTA |

| Certification | ISO |

| Model Number | Inconel 625 / UNS N06625 |

| Minimum Order Quantity | 500 kgs |

| Price | 40-45 USD/Kg |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 3 Ton per week |

Product Details

| Products | Nickel Alloy Bars | Grade | Inconel 625 / UNS N06625 |

|---|---|---|---|

| Diameter | DN6-DN400 | Length | 6000mm Or Custom Cutting Any Length As Request |

| Standard | ASTM EN | Service | Cutting |

| Loading Port | Shanghai Port | Surface | Black, Bright |

| Highlight | Cutting Nickel Alloy Pipe,Polishing Nickel Alloy Pipe,N06625 Nickel Alloy Pipe |

||

Product Description

Inconel 625 / UNS N06625 Nickel Alloy Seamless Steel Pipe Tube SS Tube Cutting and Polishing

| ASTM Specification | ASTM B444 ASME SB 444 |

|---|---|

| Standard | ASTM, ASME, JIS, AISI, AMS, EN, SAE, DIN, NF, TOCT, DS, DTD, GB |

| ASTM B444 inconel 625 Seamless Pipe Size | 4 to 219mm W. T.: 0.5 to 20mm |

| Inconel 625 Welded Pipe Size | 5.0 - 1219.2 mm |

| Inconel WERKSTOFF NR. 2.4856 EFW Pipe size | 5.0 - 1219.2 mm |

| Swg & Bwg | 12 Swg., 10 Swg., 16 Swg., 14 Swg., 20 Swg., 18 Swg., |

| Schedule | XS, SCH30, SCH40, XXS, SCH80, SCH120, SCH60, SCH140, STD, SCH10, SCH10S, SCH40S, SCH80, SCH20, SCH5, SCH160 |

| Length | Double Random, Single Random, Standard & Cut length Pipe |

| Finish | Polished, AP (Annealed & Pickled), BA (Bright & Annealed), MF, NO.1, NO.4, 2B, BA, HL, 8K, Mirror finish, etc |

| Form | inconel 625 are available in form of Round, Square, Hollow, Rectangular, Hydraulic, Coiled, Straight Pipes, “U” Shape, Pan Cake Coils etc. |

| Type | Seamless / ERW/ EFW / Welded / Fabricated / CDW / DOM / CEW inconel 625 |

| End | Plain End, Beveled End, Treaded Pipe, Screwed ends |

| Marking | All ASTM B444 inconel 625 Pipes are marked as follows: Standard, Grade, OD, Thickness, Length, Heat No. (Or according to the customer’s request.) |

| Application | Dairy Pipe, Oil Pipe, Gas Pipe, Fluid Pipe, Boiler Pipe for Chemical Industry |

| Value Added Service | Draw & Expansion as per required Size & Length, Polish (Electro & Commercial) Annealed & Pickled Bending, Machining Etc. |

| Specialize in | Large Diameter inconel 625 |

| manufacturing Technique | Cold drawn, hot drawn, bright annealed, solid solution, hot extruding |

Inconel Din 2.4856 Welded Pipe Composition Standard

| Grade | C | Mn | Si | Fe | S | Cr2 | Al-Ti | Ni | |

|---|---|---|---|---|---|---|---|---|---|

| 625 | min. | – | – | – | – | – | 20.0 | – | 58.0 |

| max. | 0.10 | 0.50 | 0.50 | 5.0 | 0.015 | 23.0 | 0.40 | – | |

ASME SB444 Alloy 625 Hexagonal Pipe Characteristics

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness | |

| Rockwell B (HR B) max | Brinell (HB) max | ||||

|---|---|---|---|---|---|

| 625 | Psi – 1,35,000 , MPa -930 | Psi – 75,000 , MPa – 517 | 42.5 | – | – |

Equivalent Grades of ASTM B444 UNS N06625 Clad Pipe

| STANDARD | WNR Material Number | JIS | EN | BS | UNS | AFNOR | GOST |

| 625 | 2.4856 | NCF 625 | NiCr22Mo9Nb | NA 21 | N06625 | NC22DNB4M | ХН75МБТЮ |

Inconel 625 Applications

Nickel alloy Inconel 625 has many different industrial applications, some of which include:

- Heat shields

- Furnace hardware

- Gas turbine engine ducting

- Combustion liners and spray bars

- Chemical plant hardware

- Special seawater applications

![]()

![]()

![]()

![]()

Recommended Products