-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

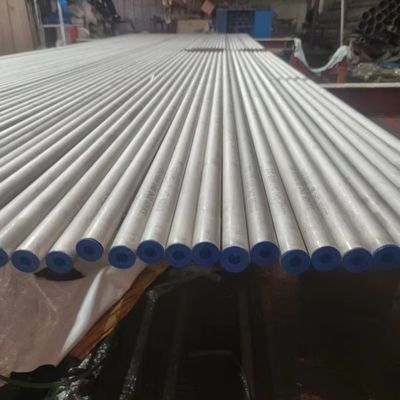

Incoloy 800 Nickel Alloy Seamless Pipe UNS N08800 Pipe Tube Thickness 1.0 - 60.0mm

| Place of Origin | China |

|---|---|

| Brand Name | DELTA |

| Certification | ISO |

| Model Number | Incoloy 800 / 800H |

| Minimum Order Quantity | 500 kgs |

| Price | 40-45 USD/Kg |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 3 Ton per week |

| Products | Nickel Alloy Bars | Grade | Incoloy 800 / 800H |

|---|---|---|---|

| Diameter | DN6-DN400 | Length | 6000mm Or Custom Cutting Any Length As Request |

| Standard | ASTM EN | Service | Cutting |

| Loading Port | Shanghai Port | Surface | Black, Bright |

| Highlight | N08800 Nickel Alloy Pipe,60.0mm Nickel Alloy Pipe,N08800 Seamless Pipe |

||

DIN 1.4876 / Alloy 800 / 800H Nickel Alloy Seamless Pipe Tubing ASTM EN DIN Standard

| Product | Nickel Alloy Pipe/Tube |

| Material | Inconel,Hastelloy,Monel,Incoloy,GH,Precision alloy,Stainless steel |

|

Standard

|

AISI,ASTM,DIN,JIS,GB,JIS,SUS,EN,etc |

| Wall Thickness | 0.2mm-300mm or as required |

| Surface Treatment | Polished/ galvanized/coated/color coated |

| Technique | Hot rolled / Cold rolled |

| Outer diameter | 600mm-2000mm or as required |

| Length | 200mm-6000mm or as required |

| Inspection | ISO,SGS,BV,MTC and so on |

| Application | High temperature components such as turbine blades, guide vanes, turbine disks, high pressure compressor disks,machine manufacturing |

| MOQ | 1Ton |

| Export Packing | Export packing standard: Waterproof paper, and steel strip packed. Covered with a layer of plastic film and cardboard, packed on the wooden pallets,bound with iron belt,loaded in the containers |

| Delivery time |

7-15days |

Incoloy800 Alloy 800 is widely used in equipment that must have high strength and resistance to oxidation, carburisation and other harmful effects of high temperature exposure. For service requiring optimum creep and rupture properties, Incoloy 800H or 800 HT are used. The high contents of nickel and chromium in the alloys also give good corrosion resistance.

Chemical Composition

ASTM B407 – Seamless Pipe & Tube

| Element | Incoloy 800 | Incoloy 800H | Incoloy 800HT |

|

Nickel

|

30.00-35.00 | 30.00-35.00 | 30.00-35.00 |

|

Chromium

|

19.00-23.00 | 19.00-23.00 | 19.00-23.00 |

|

Iron

|

39.50 min | 39.50 min | 39.50 min |

|

Carbon

|

0.10 max | 0.05-0.10 | 0.06-0.10 |

|

Aluminium

|

0.15-0.60 | 0.15-0.60 | 0.25-0.60 |

|

Titanium

|

0.15-0.60 | 0.15-0.60 | 0.25-0.60 |

|

Aluminium + Titanium

|

0.30-1.20 | 0.30-1.20 | 0.85-1.20 |

|

ASTM Grain Size

|

Not Specified | 5 or Coarser | |

Specified Minimum Mechanical Properties

| ASTM B407 – Seamless Pipe & Tube | Yield Strength |

Tensile Strength

|

Elongation

|

|

| MPa |

MPa

|

%

|

||

| Incoloy 800, 800H, 800HT | Hot Finished, Annealed | 170 | 450 | 30 |

| Incoloy 800 | Cold Worked, Annealed | 205 | 520 | 30 |

Incoloy 800 is a solid solution strengthened alloy of nickel, chromium and iron with small additions of aluminium and titanium. Incoloy 800H and Incoloy 800HT are developments of Incoloy 800, which give better performance at high temperature. ASME design codes give significantly higher design strengths for Incoloy H and HT than Incoloy 800, and allow their use to higher temperatures. AS1210 prequalifies Incoloy 800 for use to 800°C. ASME specifications allow the use of Incoloy 800 to 815°C, and of Incoloy 800H and 800HT to 982°C.

Typical Applications

Thermal processing equipment in industrial applications, such as baskets, trays, and fixtures. In chemical or petrochemical processing it is used for heat exchangers and piping systems in nitric acid media, especially where resistance to chloride stress corrosion cracking is required.

Description

Incoloy 800/800H/800HT are solid solution nickel chromium iron alloys with small additions of aluminium and titanium to improve corrosion and oxidation resistance. They are used for high temperature service, where resistance to oxidation and carburisation are required. For optimum stress rupture properties, or for pressure vessel service above 815°C, Incoloy 800H or Incoloy 800HT should be used.

Availability

Austral Wright Metals can supply these alloys as plate, sheet and strip, rod and bar, seamless and welded tube and pipe, fittings, condenser & heat exchanger tube, forgings and forging stock.

ASTM Product Specifications

| Specification | Title |

| B163 |

Seamless Nickel and Nickel Alloy Condenser and Heat Exchanger Tubes

|

| B366 |

Factory Made Wrought Nickel and Nickel Alloy Fittings

|

| B407 |

Nickel Iron Chromium Alloy Seamless Pipe and Tube

|

| B408 |

Nickel Iron Chromium Alloy Rod and Bar

|

| B409 |

Nickel Iron Chromium Alloy Plate, Sheet and Strip

|

| B514 |

Welded Nickel Iron Chromium Alloy Pipe

|

| B515 |

Welded UNS N08120, N08800, N08810 and UNS N08811 Alloy Tubes

|

| B564 |

Nickel Alloy Forgings

|

| B751 |

General Requirements for Nickel and Nickel Alloy Welded Tube

|

| B775 |

General Requirements for Nickel and Nickel Alloy Welded Pipe

|

| B829 |

General Requirements for Nickel and Nickel Alloy Seamless Pipe and Tube

|

![]()

![]()

![]()

![]()