-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

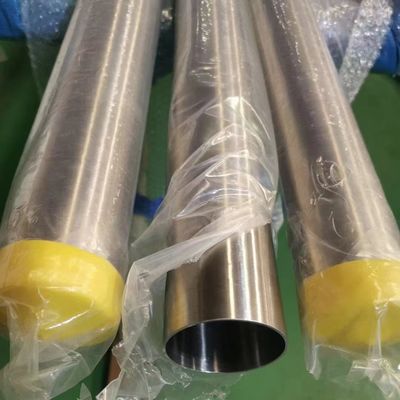

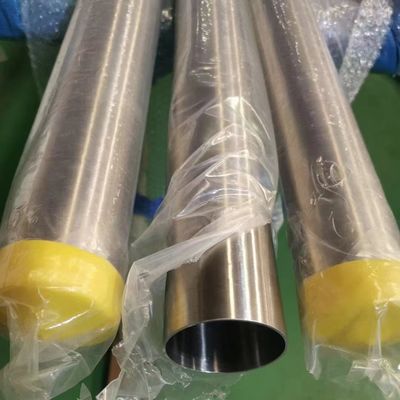

Bright (BA grade) Stainless Steel Tube Annealing TP304 TP316L Pipe ASTM A269

| Products | Stainless Steel Pipe | Grade | Stainless Steel 304 316L |

|---|---|---|---|

| Standard | ASTM GB EN | Length | 6m Or Custom Cutting Any Length As Request |

| Diameter | DN10 - DN400 | Wall Thickness | SCH10 - XXS Or Unstandard Size |

| Type | Seamless Pipe | Service | Cutting, Polishing |

| Application | Heat Exchanger | Packing | Wooden Box Or PP Bag |

| Highlight | ASTM Stainless Steel Pipe,ASTM Stainless Steel Tube,Stainless Steel Round Pipe |

||

Bright (BA grade) Stainless Steel Tube Annealing TP304 TP316L Pipe ASTM A269

| Products Name | 304 Stainless Steel Pipe |

| Pipe Type | Seamless Pipe . Welded Pipe |

| Surface | Pickling , polishing |

| Out Diameter | 6 - 508mm |

| Wall Thickness | 1.0 - 50.0mm |

| Length | 6m or cutting any length as request |

| Standard | ASTM / GB / EN / DIN / JIS / BS / BIS |

| Mainly Grade | 304 304L 304H 309S 310S 316L 316Ti 317L 321 347 2205 2507 904L 254SMO 800/800H Alloy20 ,Hastelloy Alloy, Monel Alloy,Inconel Alloy |

| Service | Cutting, Polishing, Hairline Finishing |

| MOQ | 200 Kgs |

| Packing | standard packing for export |

| Application | Industrial , food , medical, househould |

Bright annealing Stainless Steel tube

Bright annealing tube under a reducing atmosphere or in a vacuum protection, after high temperature solid melting and rapid cooling to get the stainless steel tube, requiring the inner surface has a very good surface roughness and cleanliness, is a comprehensive consideration of organizational stability corrosion resistance and workability of the pipe.

Bright annealed tube inner surface roughness Ra values and their own cleanliness is extremely demanding, so the particles can occur during transport and accumulation of fluid retention has been effectively curbed. In addition, the chemical composition of the pipe and the base material dimensional tolerances need to be strictly controlled to ensure the weldability of steel and the welding quality in the welding fumes, which can reduce the occurrence of particle generation and improving the corrosion resistance of welded parts, and smoothness.

Bright annealed stainless steel welded pipe is widely used in making military products, semiconductor, biological medicine, precision instruments and meters, hydraulic parts and many other industrial products.

Bright annealing is an annealing process performed in a vacuum or a controlled atmosphere containing inert gases (such as hydrogen). This controlled atmosphere reduces the surface oxidation to a minimum which results in a brighter surface and a much thinner oxide layer. Pickling is not needed after bright annealing since the oxidation is minimal. Since there is no pickling, the surface is much smoother which results in better resistance to pitting corrosion.

Bright annealing tube production control:

- Smelting raw materials must have good control, the level required to meet the microstructure times better level.

- Cold rolling volume control and reasonable within the organization in order to avoid defects.

- Mold control, to ensure the inner and outer surface roughness R a ≤ 0.3μm.

- Bright annealing control to ensure reasonable mechanical properties and surface brightness, and eliminate the pass mechanical polishing (MP), to ensure the smoothness of the inner surface under microscopic state, to avoid transmission fluid residues.

- Cleaning the control surfaces should have the products delivered better cleanliness and cleanliness, with metallic colors, no oil adhesion, oxide adhesion.

- Single hats loss prevention bagging, overall braid or wooden packaging.

The material of the stainless steel round bar is from Jiuli and Baosteel China, we control the quality from the very start. We polished three times to make sure the surface is perfect bright and smooth, and without any deficiency in quality.

The Bright Annealing Tube System can either be placed standalone or in-line with surface reduction equipment to create a total in-line process. Innovative design allows for easy changeover from product to product, and each system is equipped with automatic power control and precision temperature control through recipe parameters.

- Designed for ease of operation and maintenance

- Automatic speed sensor controls power proportionate to line speed

- Recipe storage and retrieval

- Integrated temperature sensing

- High wear ceramic tube guides

- Integrated pumping system

- Solid state inverters, operating in both medium and high frequencies

Bright annealing (BA) refers to stainless steel material is heated in closed furnace in reducing atmosphere of inert gases, common Hydrogen gas, after fast annealing, rapid cooling, stainless steel has a protective layer on the outer surface, no reflect in open air environment, this layer can resist corrosion attack. In general, material surface is more smooth and brighter.

Bright Annealing Stainless Steel Pipe

Tube is processed in bright annealing finish, in this process, some factors are important for quality tube, if bright annealing process is not proper, that will result in crack, then may corrosion.

Before Bright Annealing

The surface of the tube must be clean, no other foreign matter, any matter left on the tubing surface can cause damage during the process.

Inserted Gas

Annealing atmosphere should be free from Oxygen, isolating material, creating a vacuum condition. Inserted gas, common dry hydrogen or argon, can obtain bright result.

Annealing Temperature

Annealing temperature should be noticed depending on different stainless grades, commonly Austenitic steels annealing temperature is at least 1040 degree, soak time is not important. high temperature must be required to have brighter appearance. Heating is done as fast as possible, slow heat results in oxidation.

Some Ferritic stainless steels require lower annealing temperature, such as TP439, cannot be effectively bright annealed, Water quenching will cause scale formation.

Specifications

- Welded : A249, A269, A789, EN10217-7

- Seamless: A213, A269, A789

- Grade: 304, 304L, 316, 316L, 321, 2205

- Finishing: Bright annealing

Size:

- Out diameter: 3 mm – 50.8 mm;

- Wall thickness: 0.3 mm – 3 mm

- Forms: round, U bend, coiling

Stainless Steel Tube Bright Annealing Marking & Packing

- Marking according to MPS and Standard

- Stainless Steel Tubes Ends with Caps according to PO

- In Seaworthy Wooden Cases With Plastic Paper protect

- In Plywood Cases With Plastic Paper Protect(Recommend, All Plywood Cases made by ourselves with lower cost.)

- Steel Racks Package

- Hexagonal packing in Bundles

![]()

![]()

![]()

![]()