-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

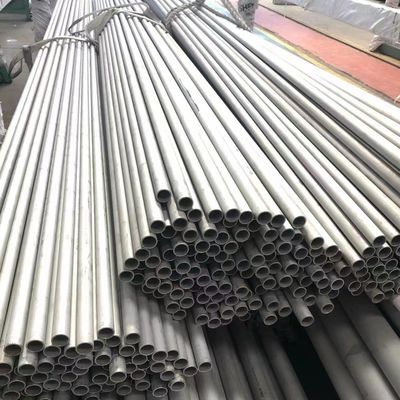

ASTM A789 Duplex S32520 Stainless Steel Seamless Pipe for Heat Exchanger and Petroleum Industry

| Products | N08020 Stainless Steel Pipe | Grade | UNS S32520 |

|---|---|---|---|

| Standard | ASTM GB EN | Length | 6m Or Custom Cutting Any Length As Request |

| Diameter | DN10 - DN400 | Wall Thickness | SCH10 - XXS Or Unstandard Size |

| Type | Seamless Pipe | Service | Cutting, Polishing |

| Application | Heat Exchanger | Packing | Wooden Box Or PP Bag |

| Highlight | ASTM Stainless Steel Pipe,ASTM Stainless Steel Tube,Stainless Steel Round Pipe |

||

ASTM A789 Duplex S32520 Stainless Steel Seamless Pipe for Heat Exchanger and Petroleum Industry

| Products Name | UNS S32520 Stainless Steel Pipe |

| Pipe Type | Seamless Pipe . Welded Pipe |

| Surface | Pickling , polishing |

| Out Diameter | 6 - 508mm |

| Wall Thickness | 1.0 - 50.0mm |

| Length | 6m or cutting any length as request |

| Standard | ASTM / GB / EN / DIN / JIS / BS / BIS |

| Mainly Grade | 304 304L 304H 309S 310S 316L 316Ti 317L 321 347 2205 2507 904L 254SMO 800/800H Alloy20 ,Hastelloy Alloy, Monel Alloy,Inconel Alloy |

| Service | Cutting, Polishing, Hairline Finishing |

| MOQ | 200 Kgs |

| Packing | standard packing for export |

| Application | Industrial , food , medical, househould |

ASME SA 789 UNS 32520 Duplex Steel Pipe for Heat Exchanger and petroleum industry

Duplex stainless steel has a signatory dual microstructure phase, which gives them heightened advantages in comparison to conventional steel. And since the ductility factor of these alloys is high, achieving an ASTM A789 UNS 32520 Duplex Stainless Steel Pipe Brighting Annealing is relatively simple. As bright annealed bars, not only do they have a smooth surface but, they can be constructed by the manufacturers, despite tight tolerances. Buyers have the option of purchasing either seamless or welded duplex steel pipes. Though with regards to its appearance, both welded and an ASME SA 789 UNS 32520 Seamless Pipe may be similar, yet dissimilar. While the shape and size of the pipe may be similar, the manner of manufacturing the UNS S32550 grade F61 Welded Pipe involves a weld seam. Though it is possible to redact the appearance of a weld seam by a significant degree, in a high pressured environment, the performance of a welded pipe is almost 20% lower than that of a seamless one. Yet, the cost-efficiency of a welded type is much higher than the former. When one speaks of the properties of duplex stainless steel alloys - their corrosion resistance is a feature that suits corrosive applications. Not to forget their performance in stress-related corrosive environments, where conventional alloys are susceptible to cracking. Cracked pipes are highly undesired in applications, where the media transported is flammable or toxic. Toxic media is highly corrosive. Either gaseous or liquid, the media flowing through pipes causes some form of friction. As the durability, corrosion resistance, and longevity of Alloy F255 UNS 32520 Pipe is much higher many buyers prefer using them. The specifications as - ASTM A790 and ASTM A789, are used in the construction of UNS S32520 EN 1.4507 Duplex Pipe. Both specifications take into consideration seamless as well as welded constructed pipes. In addition to the chemistry requirements, both specifications - ASTM A789 and ASTM A790 UNS S32520 Pipe require conformance to tests about their mechanical properties.

ASTM A789 UNS 32520 Duplex Stainless Steel Pipe sizes

ASTM A789 UNS 32520 Seamless Pipe

- Size: 4 - 406mm

- Thickness : 0.5 - 50mm

- Length: Single, Double Random & Cut Length

ASTM A789 UNS 32520 Welded Pipe

- Size: 5.0 - 1219.2 mm

- Thickness : 0.5 - 20mm

- Length: Single, Double Random & Cut Length

Duplex Stainless Steel Pipe Grade

| UNS DESIGNATION | AMERICAN (USA) SPECIFICATION |

|---|---|

| UNS S31803 | ASTM A789/ SA789 |

| UNS S32205 | ASTM A789/ SA789 |

| UNS S31500 | ASTM A789/ SA789 |

| UNS S32550 | ASTM A789/ SA789 |

| UNS S32750 | ASTM A789/ SA789 |

| UNS S32950 | ASTM A789/ SA789 |

| UNS S32520 | ASTM A789/ SA789 |

Chemical Composition of Duplex Stainless Steel Pipe

| UNS DESIGNATION | COMPOSITION, % | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| C MAX |

MN MAX |

P MAX |

S MAX |

SI MAX |

NI | CR | MO | N | CU | OTHERS | |

| S31803 | 0.03 | 2 | 0.03 | 0.02 | 1 | 4.5-6.5 | 21.0-23.0 | 2.5-3.5 | 0.08-0.20 | . . . | . . . |

| S32205 | 0.03 | 2 | 0.03 | 0.02 | 1 | 4.5-6.5 | 22-23 | 3.0-3.5 | 0.14-0.20 | . . . | . . . |

| S31500 | 0.03 | 1.20-2.00 | 0.03 | 0.03 | 1.40-2.0 | 4.3-5.2 | 18-19 | 2.5-3.0 | 0.05-0.10 | . . . | . . . |

| S32550 | 0.04 | 1.5 | 0.04 | 0.03 | 1 | 4.5-6.5 | 24-27 | 2.9-3.9 | 0.10-0.25 | 1.50-2.50 | . . . |

| S31200 | 0.03 | 2 | 0.045 | 0.03 | 1 | 5.5-6.5 | 24-26 | 1.-2.0 | 0.14-0.20 | . . . | . . . |

| S31260 | 0.03 | 1 | 0.03 | 0.03 | 0.75 | 5.5-7.5 | 24-26 | 2.5-3.5 | 0.10-0.30 | 0.20-0.80 | W 0.10-0.50 |

| S32001 | 0.03 | 4.0-6.0 | 0.04 | 0.03 | 1 | 1.0-3.0 | 19.5-21.5 | 0.6 | 0.05-0.17 | 1.00 max | . . . |

| S32304 | 0.03 | 2.5 | 0.04 | 0.04 | 1 | 3.0-5.5 | 21.5-24.5 | 0.05-0.60 | 0.05-0.20 | 0.05-0.60 | . . . |

| S32750 | 0.03 | 1.2 | 0.035 | 0.02 | 0.8 | 6.0-8.0 | 24-26 | 3.0-5.0 | 0.24-0.32 | 0.50max | . . . |

| S32760 | 0.05 | 1 | 0.03 | 0.01 | 1 | 6.0-8.0 | 24-26 | 3.0-4.0 | 0.20-0.30 | 0.50-1.00 | W 0.50-1.00 |

| S32950 | 0.03 | 2 | 0.035 | 0.01 | 0.6 | 3.5-5.2 | 26-29 | 1.0-2.5 | 0.15-0.35 | . . . | . . . |

| S32520 | 0.03 | 1.5 | 0.035 | 0.02 | 0.8 | 5.5-8.0 | 23-25 | 3.0-5.0 | 0.20-0.35 | 0.8 | . . . |

Tensile Strength of Duplex Stainless Steel Pipe

| DUPLEX GRADE | TENSILE STRENGTH, MIN., KSI [MPA] | YIELD STRENGTH, MIN., KSI [MPA] | ELONGATION IN 2 IN., OR 50MM, MIN, % | HARDNESS, MAX BRINELL |

|---|---|---|---|---|

| S31803 | 90 [620] | 65 [450] | 25 | 290 |

| S32205 | 95 [655] | 70 [485] | 25 | 290 |

| S31500 | 92 [630] | 64 [440] | 30 | 290 |

| S32550 | 110 [760] | 80 [550] | 15 | 297 |

| S31200 | 100 [690] | 65 [450] | 25 | 280 |

| S31260 | 100 [690] | 65 [450] | 25 | 290 |

| S32001 | 90 [620] | 65 [450] | 25 | 290 |

| S32304 | 100 [690] | 65 [450] | 25 | 290 |

| S32750 | 116 [800] | 80 [550] | 15 | 310 |

| S32760 | 109 [750] | 80 [550] | 25 | 300 |

| S32950 | 100 [690] | 70 [480] | 20 | 290 |

| S32520 | 112 [770] | 80 [550] | 25 |

ASME SA 789 UNS 32520 Pipe Inspection & Test reports

- Mill Test Certificates with all ASTM A789 UNS 32520 Duplex Stainless Steel Pipe

- Flattening Test

- Flaring Test

- Blow Test

- Bending Test

- Impact Test

- Hardness Test

- Exterior Size Inspection

- EN 10204/3.1B, EN 10204 3.1 and EN 10204 3.2 Material Test Certificates (MTC)

- Chemical Component Analysis

- Mechanical Properties including Ultimate Yield strength, tensile strength, Elongation

- PMI Test Reports

- Visual Inspection Reports

- Third Party Inspection for ASTM A789 UNS 32520 Pipe

- NABL Approved Lab Reports

- Non Destructive Test Reports

- Destructive Test Report

- Heat Treatment Charts

- Surface roughness measurement

- 100% Radiography Test Report

- Fumigation Certificates

- Raw Materials Certificate

- Moisture testing

- Laboratory Test Certificate from Govt. Approved Lab

- Form A for Generalized System of Preferences (GSP)

- HS Code Commercial Invoice

![]()

![]()

![]()

![]()