-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

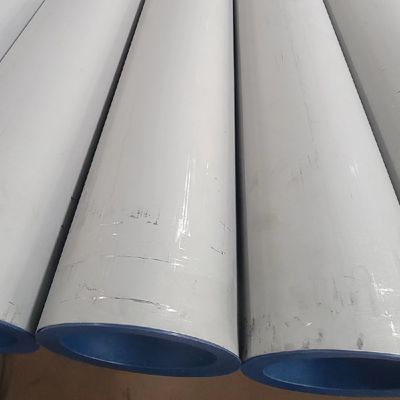

ASTM A312 Grade 321 Stainless Steel Seamless Pipe SCH40S SCH80S SCH160S SMLS Pipe

| Place of Origin | China |

|---|---|

| Brand Name | DELTA |

| Certification | ISO |

| Model Number | 304 304L 316L 316LN 316Ti 317L 321 310S 309S 347 2205 2507 904L 254SMO S32760 410S.etc |

| Minimum Order Quantity | 500 kgs |

| Price | 4000-5000 USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | T/T, Western Union, L/C |

| Supply Ability | 10 Ton per week |

| Products | Stainless Steel Pipe | Grade | 304 304L 410s 316L 316Ti 316ln 321 317L 2205 S32760 254smo 2507 310S 347 904L.etc |

|---|---|---|---|

| Standard | ASTM GB EN | Length | 6m Or Custom Cutting Any Length As Request |

| Diameter | DN10 - DN400 | Wall Thickness | SCH10 - XXS Or Unstandard Size |

| Type | Seamless Pipe | Service | Cutting, Polishing |

| Application | Heat Exchanger | Packing | Wooden Box Or PP Bag |

| Highlight | seamless stainless steel pipe,stainless steel round tube,boiler stainless steel pipe |

||

ASTM A312 Grade 321 Stainless Steel Seamless Pipe SCH40S SCH80S SCH160S SMLS Pipe

Specification of our stainless steel pipe

| Products Name | Stainless Steel pIpe |

| Diameter | DN6 - DN500 |

| Wall Thickness | SCH10S - XXS or unstandard size as request |

| Length | 6m or cutting any length as request |

| Standard | ASTM JIS EN DIN |

| Technique | Hot Rolled / cold drawn |

| Type | Seamless Pipe / Welded Pipe |

| Surface | Bright Polished, Pickling |

| Main Grade | 201 304 304L 309S 310S 316L 316Ti 316LMod 317L 321 347 410 904L 254SMO 253MA 2205 2507 654SMO 926 400 c276 c22 C4 600 625 800 825.etc |

| MOQ | 500 kgs |

| Loading Port | Shanghai Port |

| Packing | wooden box or ppbag |

About 321 Stainless Steel

Alloy 321 (UNS S32100) is a titanium stabilized austenitic stainless steel with good general corrosion resistance. It has excellent resistance to intergranular corrosion after exposure to temperatures in the chromium carbide precipitation range of 800 – 1500°F (427 – 816°C). The alloy resists oxidation to 1500°F (816°C) and has higher creep and stress rupture properties than alloys 304 and 304L. It also possesses good low temperature toughness.

Alloy 321H (UNS S 32109) is the higher carbon (0.04 – 0.10) version of the alloy. It was developed for enhanced creep resistance and for higher strength at temperatures above 1000oF (537°C). In most instances, the carbon content of the plate enables dual certification.

Alloy 321 cannot be hardened by heat treatment, only by cold working. It can be easily welded and processed by standard shop fabrication practices.

321 Stainless Steel Pipe Spefication

- ASTM A312/A312M Stainless steel seamless pipes dimention

- O.D : 1/8" NB TO 32" NB , (10.29MM-812.80MM)

- W.T: SCH 10S, SCH 40S, SCH 80S, , SCH160, SCH XXS.

- Annealed and Picked

- 100% PMI TESTED

- EN10204.3.1B MILL TEST CERTIFICATE

- THIRD PARTY INSPECTION ACCEPTED

- ASTM A312/A312M TP321 Stainless steel seamless pipes Packing.

- With plastic caps to both ends, Wrapped with Poly bags, pack into bundles. Or pack into plywood boxes as required.

TP321 Seamless Pipe Chemical Composition:

| HEAT NO. | Chemical Composition (%) | |||||||||||||

| C | Mn | P | S | Si | Ni | Cr | Mo | N | Ti | |||||

| STAND. | MIN. | 9.00 | 17.00 | / | 5 X( C +N) | |||||||||

| MAX. | 0.080 | 2.00 | 0.045 | 0.030 | 1.00 | 12.00 | 19.00 | / | / | 0.70 | ||||

TP321 Seamless Pipe Mechanical Properties:

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness | |

| Rockwell B (HR B) | Brinell (HB) | ||||

| TP321 | 515 | 205 | 35 | 90 | 187 |

Common Applications of 321 Stainless Steel Pipe

- Useful in the chromium carbide precipitation range (800-1500°F, 427-815°C)

- Aircraft exhaust stacks

- Manifolds

- Chemical processing equipment

- Welded equipment

- Jet engine parts

- Heat Exchangers

- Expansion joints

![]()

![]()

![]()

![]()