-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

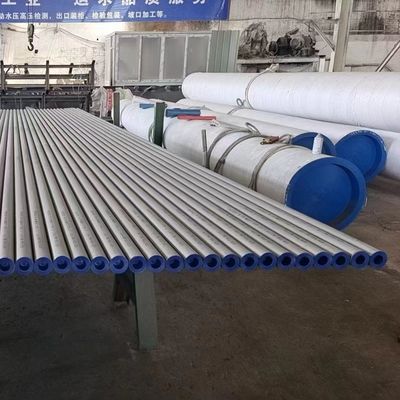

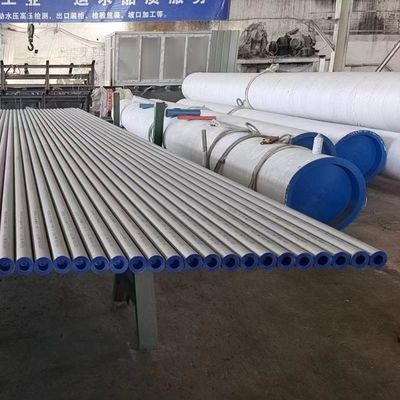

Hot Rolled Pickling Finish 304L 316L 317L Stainless Steel Seamless Pipe Tube NPS1/8-NPS80

| Place of Origin | China |

|---|---|

| Brand Name | DELTA |

| Certification | ISO |

| Model Number | 304 304L 316L 316LN 316Ti 317L 321 310S 309S 347 2205 2507 904L 254SMO S32760 410S.etc |

| Minimum Order Quantity | 500 kgs |

| Price | 4000-5000 USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | T/T, Western Union, L/C |

| Supply Ability | 10 Ton per week |

| Products | 253ma Stainless Steel Pipe | Grade | 304 304L 410s 316L 316Ti 316ln 321 317L 2205 S32760 254smo 2507 310S 347 904L.etc |

|---|---|---|---|

| Standard | ASTM GB EN | Length | 6m Or Custom Cutting Any Length As Request |

| Diameter | DN10 - DN400 | Wall Thickness | SCH10 - XXS Or Unstandard Size |

| Type | Seamless Pipe | Service | Cutting, Polishing |

| Application | Heat Exchanger | Packing | Wooden Box Or PP Bag |

| Highlight | seamless stainless steel pipe,stainless steel round tube,boiler stainless steel pipe |

||

Hot Rolled Pickling Finish 304L 316L 317L Stainless Steel Seamless Pipe Tube NPS1/8-NPS80

Products Specification of Our Stainless Steel Pipe

| Products Name | Stainless Steel pIpe |

| Diameter | DN6 - DN500 |

| Wall Thickness | SCH10S - XXS or unstandard size as request |

| Length | 6m or cutting any length as request |

| Standard | ASTM JIS EN DIN |

| Technique | Hot Rolled / cold drawn |

| Type | Seamless Pipe / Welded Pipe |

| Main Grade | 201 304 304L 309S 310S 316L 316Ti 316LMod 317L 321 347 410 904L 254SMO 253MA 2205 2507 654SMO 926 400 c276 c22 C4 600 625 800 825.etc |

| MOQ | 500 kgs |

| Loading Port | Shanghai Port |

| Packing | wooden box or ppbag |

What “L” Grades Are and Why They Are Used

The low carbon “L” grades are used for applications involving welding treatments or high temperature exposure, e.g. welding of heavy or medium sections. The low carbon content of steels prevents carbide precipitation at grain boundaries, which can cause inter-granular corrosion under corrosive operation conditions. Carbide precipitation occurs at temperatures ranging from about 450 to 850°C.

Based on their applications, “L” grade steels are available in the form of pipe, plate and, most commonly, in round bars. The corrosion resistances of standard austenitic and “L” grades are identical in the absence of high temperature exposure or welding treatments.

What “H” Grades Are and Why They Are Used

"H" grades are high carbon stainless steel grades, having improved strength at high temperatures - generally above 500°C. These high carbon grades have high short-term and long-term creep strength. They are usually produced in the form of pipe and plate. Most commonly employed grades are grade 304H and 316H, but ASTM A240/A240M also covers high carbon versions of grade 309, 310, 321, 347 and 348. When used at temperatures of about 450-850°C, these grades are subjected to sensitization which, in turn, causes aqueous corrosion, and reduction in toughness and ductility at ambient temperatures.

What the Differences Are

304 and 304L

Grades 304 and 304L have the same composition limits for all components except carbon. However, neither grade 304 nor grade 304L is specified to have minimum carbon content.

304 and 304H

Grade 304H is a high carbon version of grade 304, and it has the same composition specification as that of standard grade 304. Grade 304H does not have the 0.10% nitrogen maximum limit which is applicable to both "L" and standard grades. All austenitic "H" grades should have a grain size of ASTM No 7.

316, 316L and 316H

The three grades 316, 316L and 316H are the major counterparts of grade 304. Only the percentage of carbon contents differentiates these grades. The following table provides the carbon content of the alternatives covered under ASTM A240/A240M:

Table 1. Stainless steel carbon contents

| Grade | UNS Number | Specified Carbon Content (%) |

|---|---|---|

| 304 | S30400 | 0.08 max |

| 304L | S30403 | 0.030 max |

| 304H | S30409 | 0.04-0.10 |

| 316 | S31600 | 0.08 max |

| 316L | S31603 | 0.030 max |

| 316H | S31609 | 0.04-0.10 |

NOTE: Specifications for some other products, particularly tube and pipe, have a limit of 0.035% or 0.040% maximum for 304L and 316L, but are otherwise the same.

Property Specifications

The table below specifies the differences in mechanical properties of various grades:

Table 2. Stainless steel property specifications

| Grade | UNS | Tensile Strength (MPa) min | Yield Strength (MPa) min | Elongation (%) min | Brinell Hardness (HB) max | Rockwell Hardness (HRB)max |

|---|---|---|---|---|---|---|

| 304 | S30400 | 515 | 205 | 40 | 201 | 92 |

| 304L | S30403 | 485 | 170 | 40 | 201 | 92 |

| 304H | S30409 | 515 | 205 | 40 | 201 | 92 |

| 316 | S31600 | 515 | 205 | 40 | 217 | 95 |

| 316L | S31603 | 485 | 170 | 40 | 217 | 95 |

| 316H | S31609 | 515 | 205 | 40 | 217 | 95 |

Looking for equipment to analyze your metals?

In practice, steel mills generally ensure that the "L" grade heats meet the strength requirements of the standard grades.

Dimensional Tolerance Differences

There are no dimensional or other differences between standard, "L" and "H" grades.

Pressure Vessels

Pressure vessel codes, such as AS1210, and pressure piping codes, such as AS4041, provide allowable working pressures for each of the stainless steel grades at high temperatures. These codes provide high-pressure ratings for standard stainless steel grades when compared to that of "L" grades at any temperature. The codes avoid utilization of "L" grade steels at temperature of 425 or 525°C.

The codes consist of a clause stating that standard grades, which contain at least 0.04% carbon, must be used at temperatures above 550°C. Therefore, grades 304 or 316, having 0.02% carbon, are not allowed to be used at high temperatures. The pressure vessel codes provide the same allowable pressure rating for "H" grades.

Alternative Grade Usage

It is possible to use a product labelled as a standard grade instead of "L" or "H" grade, or vice versa, owing to the availability issues. This substitution can be made under the following conditions:

High Temperature Strength Requirements

"L" grades can be used as standard grades as long as high temperature strength is not required, and the mechanical properties conform to the standard grade requirements. "L" grades nearly always comply with the standard grade requirements, but this must be investigated on each occasion.

Tested Carbon Content - L Grades

Standard grades can be used as "L" grades if their carbon content meets the "L" grade limits of 0.030 or 0.035% maximum.

Tested Carbon Content - H Grades

Standard grades are often used instead of "H" grades as their carbon contents meet the "H" limits of 0.04 to 0.10%. Additional testing may be required to satisfy the grain size requirement. "H" grades having a maximum 0.10% of nitrogen and 0.08% of carbon are used as standard grades.

![]()

![]()

![]()

![]()