-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

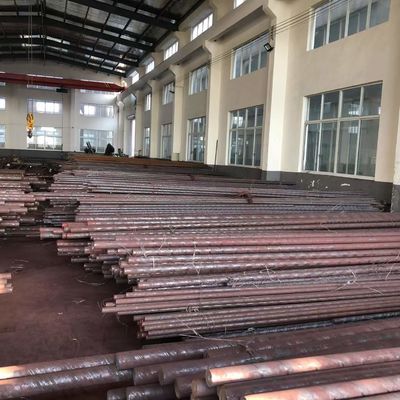

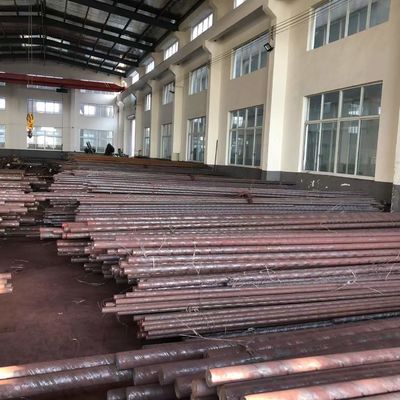

UNS S21800 Urea Grade Stainless Steel Bar for Chemical Industrial Alloy218 Stainless Steel Shaft

| Place of Origin | China |

|---|---|

| Brand Name | DELTA |

| Certification | ISO |

| Model Number | 201 304 316L 321 309S 310S 2205 17-4PH 2507 |

| Minimum Order Quantity | 500 kgs |

| Price | 2400 - 3500 USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 20Ton per week |

| Shape | Angle Bar / Channel Bar | Standard | ASTM EN GB JIS |

|---|---|---|---|

| Grade | 201 304 316L 316LMod 309S 310S 321 2205 2507.etc | Application | Construction,Industry,surgical Tools,seawater Equipment.,kitchenware |

| Length | Customers' Requirements,5.8m,6m,2m-6m,or As Required | Size | Custom As Request |

| Packing | Standard Seaworthy Package,In Wooden Cases(for FCL/ LCL Shipment) | Service | Cutting, Surface Finishing |

| Highlight | stainless steel round bar,stainless steel bar stock,steel round bar |

||

UNS S21800 Urea Grade Stainless Steel Bar for Chemical Industrial 218 Stainless Steel Shaft

UNS S21800 Urea Class Stainless Steel

UNS S21800 stainless steel offers corrosion and abrasion resistance at a much lower cost than cobalt and nickel alloys. Its overall corrosion resistance is superior to Type 304 in most media. In UNS S21800, the resistance to chloride pitting is better than Type 316. The yield strength at room temperature is almost twice that of 304 and 316. UNS S21800 has excellent high temperature oxidation resistance and low temperature impact resistance.

MATERIAL DESCRIPTION FOR UNS S21800 / ALLOY 218 / NITRONIC® 60

NITRONIC® 60 is silicon/manganese alloyed austenitic stainless steel with double yield strength of AISI 304 material. The increased silicon and manganese level inhibit wear, galling and fretting and makes the alloy fit for temperatures up to 1000°C. General corrosion resistance is between AISI 304 and 316. It offers better chloride pitting resistance, stress corrosion cracking resistance and crevice corrosion resistance than AISI 316L in laboratory conditions.

Standard Specification of UNS S21800 / Nitronic 60 Alloy Stainless Steel

Specifications |

||

|---|---|---|

| Form | Standard | |

|

Bar |

ASTM A193 ASTM A194 ASTM A276 ASTM A479 F899 AMS 5848 |

|

|

Wire |

|

|

|

Sheet |

ASTM A240 F899 |

|

|

Plate |

ASTM A240 F899 |

|

|

Fitting |

|

|

|

Forging |

ASTM A182 |

|

|

Weld Wire |

A5.9 ER218 |

|

Applications

- Automotive valves - can withstand gas temperatures of upto 1500°F for a minimum of 50,000 miles.

- Fastener galling - capable of frequent assembly and disassembly, allowing more use of the fastener before the threads are torn up, also helps to eliminate corroded or frozen fasteners.

- Pins - Used in roller prosthetics & chains to ensure a better fit of parts (closer tolerance, non-lubricated) and longer lasting.

- Marine shafts - better corrosion than types 304 and 316, with double the yield strength.

- Pin and hanger expansion joints for bridges - better corrosion, galling-resistance, low temperature toughness, & high charpy values at sub-zero temps compared to the A36 and A588 carbon steels commonly used.

Heat Treatment

Annealed at 1066°C followed by water quenching.

Chemical composition of UNS S21800 Alloy

| Weight % | C | Si | Mn | S | P | Cr | Ni | Mo | N |

| Min. | 3,50 | 7,00 | 16,00 | 8,00 | 0,08 | ||||

| Max. | 0,10 | 4,50 | 9,00 | 0,030 | 0,060 | 18,00 | 9,00 | 0,75 | 0,18 |

Product Standards: ASTM A276, ASTM A479

Mechanical properties of UNS S21800 Alloy

| Yield strength Rp0.2, MPa |

Tensile Strength Rm, MPa |

Elongation [%] |

Hardness [HB] |

Impact, Charpy-V, -196ºC [J] |

|

| BAR | ≥ 345 | ≥ 655 | 35 | ≤ 241 | 150 |

| Typical | 400 | 720 | 55 | 200 |

Applications

- Automotive valves - can withstand gas temperatures of upto 1500°F for a minimum of 50,000 miles.

- Fastener galling - capable of frequent assembly and disassembly, allowing more use of the fastener before the threads are torn up, also helps to eliminate corroded or frozen fasteners.

- Pins - Used in roller prosthetics & chains to ensure a better fit of parts (closer tolerance, non-lubricated) and longer lasting.

- Marine shafts - better corrosion than types 304 and 316, with double the yield strength.

- Pin and hanger expansion joints for bridges - better corrosion, galling-resistance, low temperature toughness, & high charpy values at sub-zero temps compared to the A36 and A588 carbon steels commonly used.

![]()

![]()

![]()

![]()