All Products

-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

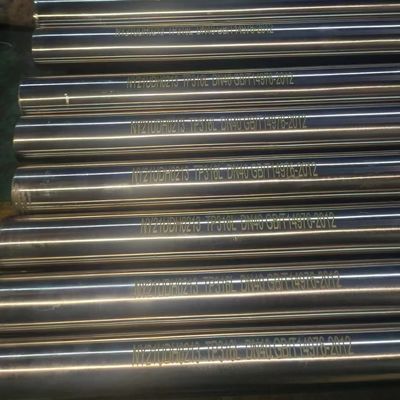

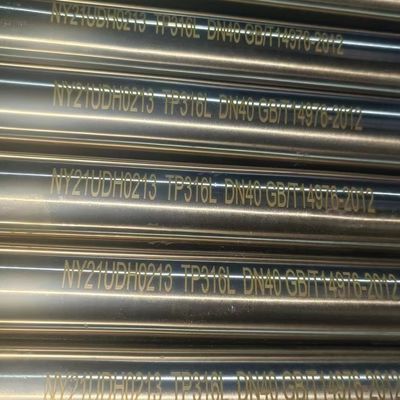

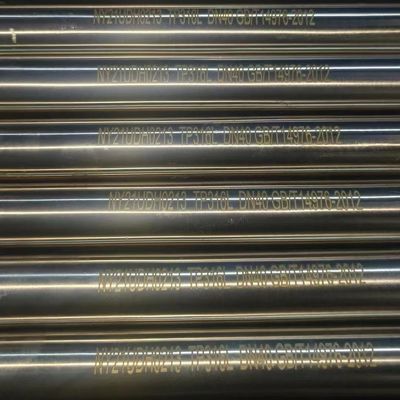

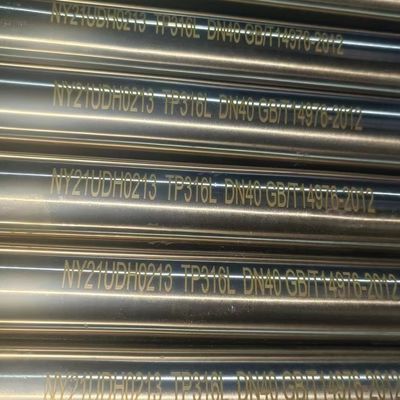

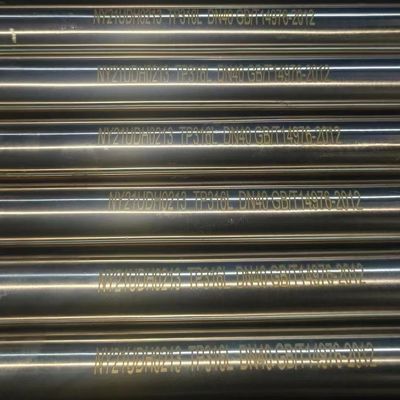

DN 10 - DN300 Stainless Steel TP316L Pipe Tube / 1.4404 Stainless Pipe SCH40 SCH80S

| Place of Origin | China |

|---|---|

| Brand Name | DELTA |

| Certification | ISO |

| Model Number | 201 304 316L 321 310S 314 347 2205 2507 904L.etc |

| Minimum Order Quantity | 500 kgs |

| Price | 2400 - 3500 USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | T/T, Western Union, L/C |

| Supply Ability | 10 Ton per week |

Product Details

| Products | Bright Polished Stainless Steel Pipe | Grade | 304 316L 321 2205 310S 904L.etc |

|---|---|---|---|

| Standard | ASTM GB EN | Length | 6m Or As Request |

| Diameter | 6 - 219mm Or As Clients Request | Wall Thickness | 0.2 - 8.0mm |

| Type | Welded Pipe | Service | Cutting |

| Other Shape | Square, Rectangle | ||

| Highlight | DN300 Stainless Steel Pipe,SCH80S Stainless Steel Pipe,1.4404 Stainless Steel Pipe |

||

Product Description

DN 10 - DN300 Stainless Steel TP316L Pipe Tube / 1.4404 Stainless Pipe SCH40 SCH80S

| ASTM / ASME Grade | ASTM A312 / ASTM SA 312 |

| Dimensional ANSI Specifications | ANSI/ ASME B36.19M, ANSI/ ASME B36.10M |

| Different Types and Forms | Rectangle, Hex, Honed, Square, Round, Hydraulic Pipe supplier |

| Basic types we produce | 100% X Ray Welded, CDW, ERW, Welded, Seamless, Fabricated |

| Pipe End Bevel | Plain, Beveled and Treaded End |

| Delivery & Finished Condition | Bright Annealed, Cold Drawn, Polished, Annealed and Pickled, Pickled and Passivated |

| Mechanical Surface Finish | 2B, No.4, No.1, No.8 Mirror Finish or custom Finish as per customer Requirements |

| ASTM A312 TP316L Wall Thickness | SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS |

| Other Facilities we offer | Grooving, Threading, Machining, Ultrasonic Testing, Customer Tagging/ Marking, Destructive, MTR’s Available, Threading, Polishing, Export Documentation, Non Destructive, Beveling, Export Packaging, Cutting, Color Coding, Material testing |

| SS 316L Pipes Marking |

Marked Pipe Sample: ANSI B36.19 ASTM A312 TP316L 12" NB SCH 60S SEAMLESS HEAT NO. XXXX |

| Dual certified 316L Pipe supplier | Dual certification : To certify ASTM A312 316L and ASME SA312 316L material specification |

316L Stainless Steel Pipe for sale

| SS UNS S31603 Box Pipes | SA312 316L Stainless Steel Threaded Pipes |

| werkstoff nr. 1.4436 Stainless Steel 316L C Class Pipes | TP 316L Stainless Steel DIN 1.4436 Water Pipes |

| Stainless Steel UNS S31603 Dairy Pipes | ASTM A312 SS 316L Rectangular Pipes |

| A312 GR TP316L Square Pipes | Austenitic Stainless Steel 316L Round Pipes |

| A312 TP 316L Seamless Pipes | ASTM A312 TP316L Exhaust Pipes |

| TP 316L Stainless Steel Hollow Pipes | A312 TP316L Schedule 40 Pipes |

| ASTM A 312 TP 316L Stainless Steel Schedule 80 Pipes | SA 312 TP 316L 3 Inch Pipes |

| ASTM A312 GR TP316L Schedule 10 Pipes | TP 316L Stainless Steel DIN 1.4436 Erw Pipes |

| A312 Stainless Steel 316L Electropolished Pipes | ASTM A312 SS 316L Polished Pipes |

ASTM A312 TP316L Equivalent grades

| GRADE | UNS | WERKSTOFF NR. | JIS | AFNOR | BS | GOST | EN | SS |

| USA | GERMAN | JAPAN | RUSSIAN | BRITISH | RUSSIAN | EUROPE | SWEDISH | |

| TP 316L | S31603 | 1.4404 / 1.4435 | SUS 316L | Z3CND17‐11‐02 / Z3CND18‐14‐03 | 316S11 / 316S13 | 03Ch17N14M3 / 03Ch17N14M2 | X2CrNiMo17-12-2 / X2CrNiMo18-14-3 | 2348 |

ASTM A312 TP316L allowable stress

| SPECIFICATION | SA-312 | SA-312 |

|---|---|---|

| SS Grade | TP316L | TP316L |

| Nominal Composition | 16Cr-12Ni-2Mo | 16Cr-12Ni-2Mo |

| Product Shape | Welded pipe | Seamless & Welded pipe |

| UNS designation | S31603 | S31603 |

| Sizes/ Thickness [mm] | - | - |

| P Number | 8 | 8 |

| Group Number | 1 | 1 |

| Minimum Tensile Strength [MPa] |

485 | 485 |

| Minimum Yield Strength [MPa] |

170 | 170 |

| I-Applic. and Maximum temperature limit [°C] |

454 | 454 |

| III-Applic. and Maximum temperature limit [°C] | NP | 427 |

| VIII-1-Applic. and Maximum temperature limit [°C] | 454 | 454 |

| XII-Applic. and Maximum temperature limit [°C] | 343 | 343 |

| External Pressure Chart No. |

HA-4 | HA-4 |

316L Pipe Dimensions

| SIZES | OUTSIDE DIAMETER | WALL THICKNESS | WEIGHT |

|---|---|---|---|

| 1/8 inches | 0.405 inches 10.287 mm |

0.068 inches 1.7272 mm |

0.245 lbs/ft 0.36460018 kg/m |

| 1/4 inches | 0.54 inches 13.716 mm |

0.088 inches 2.2352 mm |

0.425 lbs/ft 0.6324697 kg/m |

| 3/8 inches | 0.675 inches 17.145 mm |

0.091 inches 2.3114 mm |

0.568 lbs/ft 0.845277152 kg/m |

| 1/2 inches | 0.84 inches 21.336 mm |

0.109 inches 2.7686 mm |

0.851 lbs/ft 1.266427564 kg/m |

| 3/4 inches | 1.05 inches 26.67 mm |

0.113 inches 2.8702 mm |

1.131 lbs/ft 1.683113484 kg/m |

| 1 inches | 1.315 inches 33.401 mm |

0.133 inches 3.3782 mm |

1.68 lbs/ft 2.50011552 kg/m |

| 1 1/4 inches | 1.66 inches 42.164 mm |

0.140 inches 3.556 mm |

2.274 lbs/ft 3.384084936 kg/m |

| 1 1/2 inches | 1.9 inches 48.26 mm |

0.145 inches 3.683 mm |

2.719 lbs/ft 4.046317916 kg/m |

| 2 inches | 2.375 inches 60.325 mm |

0.154 inches 3.9116 mm |

3.654 lbs/ft 5.437751256 kg/m |

| 2 1/2 inches | 2.875 inches 73.025 mm |

0.203 inches 5.1562 mm |

5.795 lbs/ft 8.62391038 kg/m |

| 3 inches | 3 1/2 inches 88.90 mm |

0.216 inches 5.4864 mm |

7.579 lbs/ft 11.278794956 kg/m |

| 3 1/2 inches | 4 inches 101.6 mm |

0.226 inches 5.7404 mm |

9.113 lbs/ft 13.561638532 kg/m |

| 4 inches | 4.500 inches 114.3 mm |

0.237 inches 6.0198 mm |

10.794 lbs/ft 16.063242216 kg/m |

| 5 inches | 5.563 inches 141.3002 mm |

0.258 inches 6.5532 mm |

14.623 lbs/ft 21.761422172 kg/m |

| 6 inches | 6.625 inches 168.275 mm |

0.280 inches 7.112 mm |

18.981 lbs/ft 28.246840884 kg/m |

| 8 inches | 8.625 inches 219.075 mm |

0.322 inches 8.1788 mm |

28.564 lbs/ft 42.507916496 kg/m |

| 10 inches | 10.75 inches 273.05 mm |

0.365 inches 9.271 mm |

40.498 lbs/ft 60.267665672 kg/m |

| 12 inches | 12.75 inches 323.85 mm |

0.375 inches 9.5250 mm |

49.580 lbs/ft 73.78317112 kg/m |

AISI 316L Pipe Chemical Composition

| ASTM A312 | C | Mn | Si | P | S | Cr | Mo | Ni | N | |

| TP316L | min. | - | - | - | - | - | 16.0 | 2.0 | 10.0 | - |

| max. | 0.08 | 2.0 | 0.75 | 0.045 | 0.03 | 18.0 | 3.0 | 14.0 | 0.10 | |

SA 312 TP 316L Pipe Standard

| STANDARD | SS 316L |

|---|---|

| ASTM | A312 |

| ASME | SA 312 |

| WERKSTOFF NR. / DIN | 1.4404 / 1.4435 |

| UNS | S31603 |

| JIS | SUS 316L |

| AFNOR | Z3CND17-11-02 / Z3CND18-14-03 |

ASTM A312 TP 316L Stainless Steel Pipe Roughness

| MATERIAL SURFACE | ABSOLUTE ROUGHNESS COEFFICIENT Ε MM |

|---|---|

| Aluminum Alloy, Lead | 0.001 - 0.002 |

| Drawn Copper/ Brass | 0.0015 |

| 316L Stainless Steel | 0.015 |

316L Pipe Hardness

| GRADE | ROCKWELL B HARDNESS (HR B) MAX | BRINELL HARDNESS (HB) MAX |

|---|---|---|

| 316L | 95 | 217 |

SS 316L Pipe Schedule Chart

| OD | O/D | NOMINAL WALL THICKNESS (NPS) | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DIA | SCHEDULE.5S | SCHEDULE.5 | SCHEDULE 10S | SCHEDULE.10 | SCHEDULE.20S | SCHEDULE.30 | SCHEDULE.40S | SCHEDULE.40 | SCHEDULE 60 | |||||||||||

| (A) | (B) | METER MM |

WALL THK |

WEIGHT KG/MTR | WALL THK |

WEIGHT KG/MTR | WALL THK |

WEIGHT KG/MTR | WALL THK |

WEIGHT KG/MTR | WALL THK |

WEIGHT KG/MTR | WALL THK |

WEIGHT KG/MTR | WALL THK |

WEIGHT KG/MTR | WALL THK |

WEIGHT KG/MTR | WALL THK |

WEIGHT KG/MTR |

| 6 | 1/8 | 10.3 | 1 | 0.23 | 1.2 | 0.27 | 1.5 | 0.33 | 1.73 | 0.37 | ||||||||||

| 8 | 1/4 | 13.7 | 1.2 | 0.37 | 1.65 | 0.49 | 2 | 0.58 | 2.24 | 0.64 | ||||||||||

| 10 | 3/8 | 17.2 | 1.2 | 0.47 | 1.65 | 0.63 | 2 | 0.74 | 2.31 | 0.87 | ||||||||||

| 15 | 1/2 | 21.3 | 1.65 | 0.01 | 1.65 | 0.81 | 2.11 | 1.02 | 2.11 | 1.02 | 2.5 | 1.15 | 2.77 | 1.29 | ||||||

| 20 | 3/4 | 26.7 | 1.65 | 1.03 | 1.65 | 1.03 | 2.11 | 1.3 | 2.11 | 1.3 | 2.5 | 1.49 | 2.87 | 1.71 | ||||||

| 25 | 1 | 33.4 | 1.65 | 1.31 | 1.65 | 1.31 | 2.77 | 2.13 | 2.77 | 2.13 | 3 | 2.24 | 3.38 | 2.54 | ||||||

| 32 | 11/4 | 24.2 | 1.65 | 1.67 | 1.65 | 1.67 | 2.77 | 2.73 | 2.77 | 2.73 | 3 | 2.9 | 3.56 | 3.44 | ||||||

| 40 | 11/2 | 48.3 | 1.65 | 1.93 | 1.65 | 1.93 | 2.77 | 3.16 | 2.77 | 3.16 | 3 | 3.35 | 3.68 | 4.11 | ||||||

| 50 | 2 | 60.3 | 1.65 | 1.93 | 1.65 | 2.42 | 2.77 | 3.99 | 2.77 | 3.99 | 3.5 | 4.9 | 3.91 | 5.52 | ||||||

| 65 | 21/2 | 73 | 2.11 | 3.75 | 2.11 | 3.75 | 3.05 | 5.34 | 3.05 | 5.34 | 3.5 | 6 | 5.16 | 8.77 | ||||||

| 80 | 3 | 88.9 | 2.11 | 4.59 | 2.11 | 4.59 | 3.05 | 6.56 | 3.05 | 6.56 | 4 | 8.37 | 5.49 | 11.47 | ||||||

| 90 | 31/2 | 101.6 | 2.11 | 5.25 | 2.11 | 5.25 | 3.05 | 7.53 | 3.05 | 7.53 | 4 | 9.62 | 5.74 | 13.78 | ||||||

| 100 | 4 | 114.3 | 2.11 | 5.93 | 2.11 | 5.93 | 3.05 | 8.5 | 3.05 | 8.5 | 4.5 | 12.18 | 6.02 | 6.32 | ||||||

| 125 | 5 | 141.3 | 2.77 | 9.61 | 2.77 | 9.61 | 3.4 | 11.74 | 3.43 | 11.74 | 5 | 16.8 | 6.55 | 2210 | ||||||

| 150 | 6 | 168.3 | 2.77 | 11.47 | 2.77 | 11.47 | 3.4 | 14.04 | 3.43 | 14.04 | 5.5 | 22.08 | 7.11 | 28.69 | ||||||

| 200 | 8 | 219.1 | 2.77 | 15 | 2.77 | 15 | 3.76 | 20.77 | 3.76 | 20.27 | 6.35 | 33.82 | 7.04 | 37.38 | 8.18 | 43.2 | 10.81 | 53.9 | ||

| 250 | 10 | 273.1 | 3.4 | 22.95 | 3.4 | 22.95 | 4.19 | 28.2 | 4.19 | 28.2 | 6.35 | 42.41 | 7.8 | 51.81 | 9.27 | 61.22 | 12.2 | 82.8 | ||

| 300 | 12 | 323.9 | 3.96 | 31.72 | 4.19 | 33.6 | 4.57 | 36.54 | 4.57 | 36.54 | 6.35 | 50.48 | 8.38 | 66.2 | 9.53 | 75.01 | 10.31 | 80.94 | 14.27 | 110.62 |

| 350 | 14 | 355.6 | 3.96 | 34.86 | 4.78 | 41.99 | 6.35 | 55.53 | 7.92 | 68.95 | 9.53 | 82.58 | 9.53 | 82.58 | 11.13 | 96 | 15.06 | 128.42 | ||

| 400 | 16 | 406.4 | 4.19 | 42.2 | 4.78 | 48.07 | 6.35 | 63.61 | 7.92 | 79.03 | 9.53 | 94.7 | 9.53 | 94.7 | 12.7 | 125.2 | 16.66 | 162.59 | ||

| 450 | 18 | 457.2 | 4.19 | 47.46 | 4.78 | 54.15 | 6.35 | 71.69 | 7.92 | 89.1 | 11.13 | 124.32 | 9.53 | 106.83 | 14.27 | 158.27 | 19.05 | 209 | ||

| 500 | 2C | 508 | 4.78 | 60.23 | 5.54 | 69.7 | 6.35 | 79.76 | 9.53 | 118.93 | 12.7 | 157.51 | 9.53 | 118.9 | 15.06 | 185.89 | 2062 | 251.65 | ||

| 550 | 22 | 558.8 | 4.78 | 65.95 | 5.54 | 76.75 | 6.35 | 87.84 | 9.53 | 131.07 | 12.7 | 173.66 | 9.53 | 131.07 | 15.88 | 216.04 | 22.23 | 298.55 | ||

| 600 | 24 | 609.6 | 5.54 | 83.8 | 6.35 | 95.92 | 6.35 | 95.92 | 9.53 | 143.2 | 14.27 | 212.72 | 9.53 | 143.2 | 17.45 | 258.74 | 24.59 | 360.21 | ||

| 650 | 26 | 660.4 | 7.92 | 129.4 | 12.7 | 205.97 | 9.53 | 155.32 | ||||||||||||

| 700 | 28 | 711.2 | 7.92 | 139.47 | 12.7 | 222.13 | 15.88 | 276.48 | 9.53 | 167.44 | ||||||||||

| 750 | 3C | 762 | 6.35 | 120.15 | 7.92 | 149.55 | 7.92 | 149.55 | 12.7 | 238.28 | 15.88 | 296.68 | 9.53 | 179.56 | ||||||

| 800 | 32 | 812.8 | 7.92 | 159.62 | 12.7 | 254.44 | 15.88 | 316.88 | 9.53 | 191.69 | 17.48 | 348.11 | ||||||||

| 850 | 34 | 863.6 | 7.92 | 169.64 | 12.7 | 270.5 | 15.88 | 336.96 | 9.53 | 203.74 | 17.48 | 370.22 | ||||||||

| 900 | 36 | 914.4 | 7.92 | 179.77 | 12.7 | |||||||||||||||

ASME SA 312 TP 316L Pipe Mechanical Properties

| ASTM A312 | Tensile Stress (MPa) min | Yield Stress 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness | |

| Rockwell B (HR B) max | Brinell (HB) max | ||||

| TP316L | 515 | 205 | 40 | 95 | 217 |

A312 Gr TP 316L Stainless Steel Pipe Yield Strength

0.2% Proof (MPa) min

| GRADE | YIELD STRENGTH |

|---|---|

| 316L | 170 |

316L Stainless Steel Pipe Temperature Rating

| GRADE | MEAN CO-EFF OF THERMAL EXPANSION (ΜM/M/°C) | THERMAL CONDUCTIVITY TEMPERATURE (W/M.K) | ELEC RESISTIVITY (NΩ.M) | SPECIFIC HEAT 0-100 °C (J/KG.K) | |||

|---|---|---|---|---|---|---|---|

| 0-100 °C | 0-315 °C | 0-538 °C | AT 100 °C | AT 500 °C | |||

| 316L | 15.9 | 16.2 | 17.5 | 16.3 | 21.5 | 740 | 500 |

AISI 316L Stainless Steel Pipe Tolerances

Nominal pipe size (NPS)

- up to 4 = ± 0.79 mm | 5 thru 8 = + 1.58 mm / - 0.79 mm

- 10 thru 18 = + 2.37 mm / - 0.79 mm | 20 thru 24 = + 3.18 mm / - 0.79 mm

| WALL THICKNESS (WT) | LENGTH | WEIGHT |

|---|---|---|

|

All Diameters = - 12.5% + tolerance not specified |

+ 6.40 mm / - 0 mm | Weight = + 10% / - 1.5% |

Why choose SS 316L Pipe manufacturers instead of a supplier?

- Avoid supplier commission & get lowest price

- All manufacturers provides MTC and MTR test reports with each delivery

- Custom sizes can be produced, depends on the quantity

- 100% exchange and return policy

- Assured High quality material

- Ready sizes to save cost and time

![]()

![]()

![]()

![]()

Recommended Products