-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

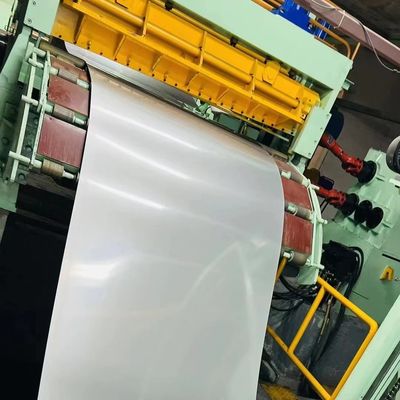

ASTM A240 UNS S32750 Duplex Stainless Steel Plate & Sheet 0.4 - 30.0mm from POSCO DIN 1.4410 Alloy 2507

| Place of Origin | China |

|---|---|

| Brand Name | TISCO BAOSTEEL |

| Certification | ISO |

| Model Number | 2507/ 1.4410 / UNS S32750 |

| Minimum Order Quantity | 500 kgs |

| Price | 4000-6000 USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | T/T, Western Union |

| Supply Ability | 20Ton per week |

| Products | Stainless Steel Plate | Grade | 2507 / 1.4410 / UNS S32750 |

|---|---|---|---|

| Thickness | 0.4-30.0mm | Width | 1500mm 1219mm 1000mm |

| Surface | NO.1 2B | Brand | POSCO TISCO |

| Standard | ASTM A240/240M | Loading Port | Shanghai Port |

| Highlight | Alloy 2507 Duplex Stainless Steel Plate,DIN 1.4410 Duplex Stainless Steel Plate |

||

ASTM A240 UNS S32750 Duplex Stainless Steel Plate & Sheet 0.4 - 30.0mm from POSCO DIN 1.4410 Alloy 2507

| Products | 2507 / UNS S32750 / 1.4410 Duplex Stainless Steel Plate | |||

|

Width

|

1000mm/1219mm/1240mm/1500mm/2000mm or as customer's requirements

|

|||

|

Thickness

|

cold rolled: 0.1-3mm; hot rolled: 3-100mm

|

|||

|

Length

|

100mm to 12000mm or as customer's request

|

|||

|

Surface

|

N0.1, N0.4, 2D, 2B, HL, BA, 6K, 8K, Mirror,etc

|

|||

|

Material

|

201,202,301,302,303,304,304L,304N1,309S,310S,316,316L, 316Ti,316N,317,317L,321,409L,410,420,430,904,904L,etc

|

|||

|

Grade

|

200/300/400/500/600/700/800/900 series/duplex stainless steel

|

|||

|

Standards

|

AISI ASTM JIS SUS DIN GB

|

|||

|

Brand

|

TISCO,ZPSS,Baosteel,POSCO,LISCO,YUSCO,Ansteel, QPSS,JISCO, HXSCO,Chengde,Yongjin,Tsingshan,Shouyang,

|

|||

Alloy 32750 is a super duplex stainless steel supplied in the hot worked and solution annealed condition. As a super duplex stainless steel, it combines the desirable aspects of both austenitic and ferritic grades. The higher chromium, molybdenum and nitrogen contents result in a Pitting Resistance Equivalent number (PREN) of >40, providing pitting and crevice corrosion resistance superior to austenitic and duplex stainless steels in almost all corrosive media, and a Critical Pitting Temperature exceeding 50°C.

Supplied in the annealed condition it achieves yield strengths of 80ksi (550Mpa), greater than most austenitic and duplex stainless steel grades. It cannot be hardened by heat treatment but can be strengthened by cold working. It also exhibits a low coefficient of thermal expansion and higher heat conductivity than austenitic steels and is suitable for working temperatures up to 300°C. Alloy 32750 is listed in NACE MR 0175 for sour service and having gained ASME Approval for Pressure Vessel applications it can be used in a wide variety of applications.

Regular Stock Size of Our 32750 Duplex Stainless Steel Plate

| Cold Rolled 32750 Sheet | Hot Rolled 32750 Plate | ||

| Thickness | Size | Thickness | Size |

| 0.4mm | 1000*2000mm | 4.0mm | 1500*6000mm |

| 0.5mm | 1000*2000mm | 5.0mm | 1500*6000mm |

| 0.6mm | 1219*2438mm | 6.0mm | 1500*6000mm |

| 0.7mm | 1219*2438mm | 8.0mm | 1500*6000mm |

| 0.8mm | 1219*2438mm | 10.0mm | 1500*6000mm |

| 1.0mm | 1219*2438mm | 12.0mm | 1500*6000mm |

| 1.2mm | 1219*2438mm | 14.0mm | 1500*6000mm |

| 1.5mm | 1219*2438mm | 16.0mm | 1500*6000mm |

| 2.0mm | 1219*2438mm | 20.0mm | 1500*6000mm |

| 2.5mm | 1219*2438mm | 25.0mm | 1500*6000mm |

| 3.0mm | 1219*2438mm | 30.0mm | 1500*6000mm |

Chemical Composition of UNS S32750 Duplex Stainless Steel

| Cr | Ni | Mo | Co | C | Mn | N | Si | P | S | Fe | Al | |

| Min | 24.00 | 6.00 | 3.00 | 0.24 | ||||||||

| Max | 26.00 | 8.00 | 5.00 | 0.50 | 0.03 | 1.20 | 0.32 | 0.80 | 0.035 | 0.02 | Bal |

Mechanical Properties:

| 0.2% Proof Stress | 550 N/mm2 | 79.8 ksi |

| Tensile Strength | 795 N/mm2 | 115 ksi |

| Elongation, 5.65√S0 | 25% | |

| Reduction of area | 45% | |

| Hardness (Brinell) | 220-270 | |

| Impact Strength (Room Temp) | 80J | |

| Impact Strength (-46oC) | 45J (minimum 35J) |

Notes:

- Hardness shall be in accordance with NACE MR 1075 with a maximum HRC of 28

- Testing performed on each melt of material per heat treatment batch

- Impact strength values for plate > 5mm thickness only

- Minimum properties quoted (tested at room temperature in a longitudinal direction)

- Testing shall be carried out in accordance with ASTM A370 or EN ISO 6892-1 (tensile), EN ISO 6506-1 (hardness)

- ASTM G48A corrosion test (at 50°C) no pitting and < 3.0g/m2 weight loss (ASTM specification < 4.0g/m2)

- Ferrite content 40-55%

- Microstructure certified free from grain boundary carbides, sigma, chi and laves phases

Key Features:

- Excellent corrosion resistance in a wide variety of corrosive chemicals

- Pitting Resistance Equivalent number (PREN) of >40

- Outstanding resistance to pitting and crevice corrosion in seawater and other chloride containing environments

- Critical Pitting Temperature exceeding 50°C

- High strength compared to austenitic and 22%Cr duplex stainless steels

- Excellent ductility and impact strength at both ambient and sub-zero temperatures

- High resistance to abrasion, erosion and cavitation erosion

- Excellent resistance to stress corrosion cracking in chloride containing environments

- Listed in NACE MR 0175 for sour service

- ASME Approval for Pressure Vessel application

Applications:

- Process industry components in nitric acid, dioxide, polypropylene & PVC production, caustic evaporators

- Equipment handling organic & fatty acids

- Marine industry and shipbuilding propellers, shafts, rudders, shaft seals, pumps, bolts, fasteners, valves, instrumentation

- Oil and chemical tankers

- Oil & Gas industry pumps, valves, pipe, vessels, wellhead equipment, subsea equipment

- Pollution control systems, fans and pumps, wet scrubbers, incinerators, flue gas desulphurisation (FGD)

- Pulp & paper industry components such as black liquor heater tubes, digester blow valves, rotary feed valves, I.D.fans, brownstock washers, precipitators, bleaching components

- Food Industry applications including sugar cane centrifuges, corn and vegetable processing plant

- Agrochemicals production such as fertilisers (based on wet phosphoric acid)

- Sewage treatment, seawater cooling, desalination plants

![]()

![]()

![]()

![]()